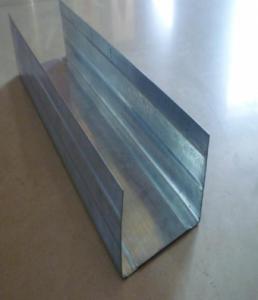

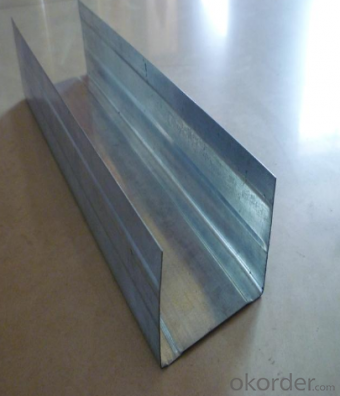

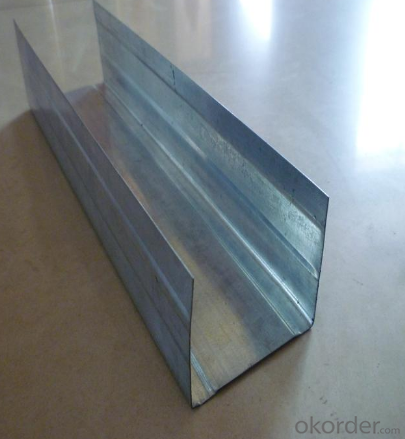

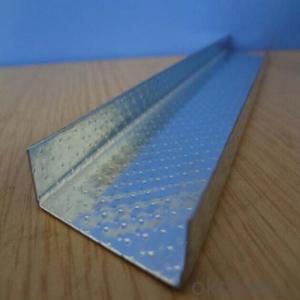

Galvanized stud for gypsum drywall metal stud and track

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized stud for gypsum drywall

Instruction

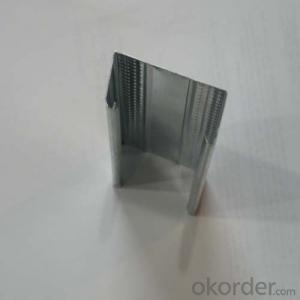

Drywall Metal Profile

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

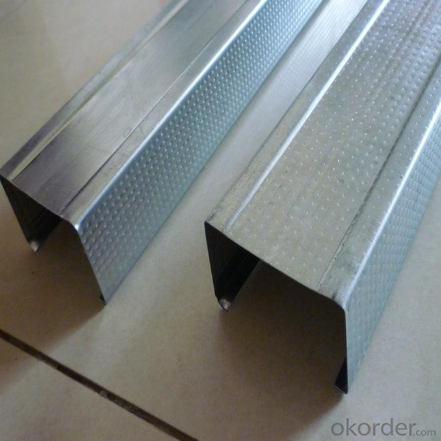

Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe,

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Galvanized steel profile / metal stud gypsum drywall

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

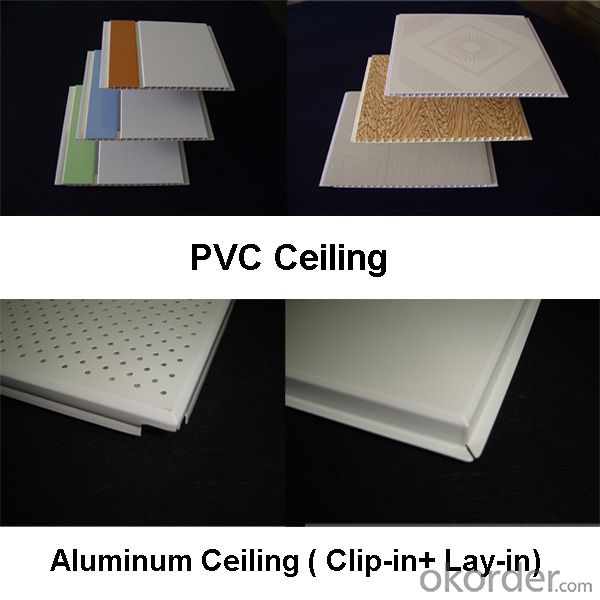

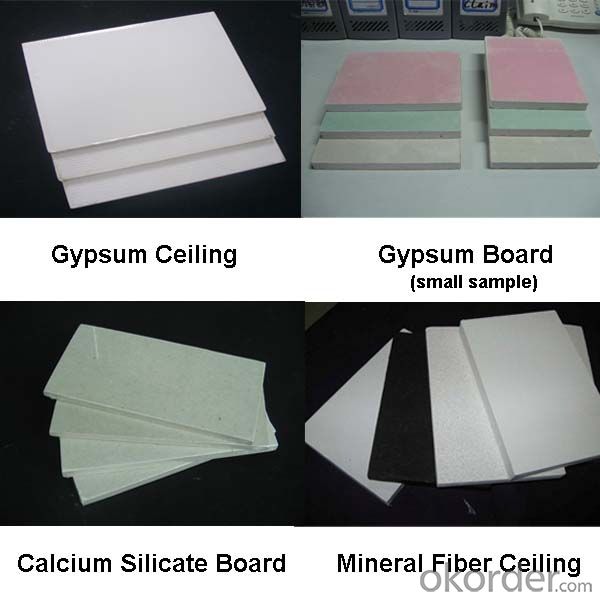

Other products we supply:

Galvanized steel profile / metal stud gypsum drywall

- Q: Light steel keel partition wall fire retardant coating shabu several surface

- Grass-roots side of the wooden side need to brush four sides, the base liner is two sides, but the paste surface layer of decorative panels generally just brush a back, the front is usually not brush fire paint, or should be the quality of surface layer decorative plate paste.

- Q: Light steel keel gypsum board wall height is how to determine

- According to the British standard BS5234, different use of the partition wall has different stiffness requirements, the maximum height of the partition wall to determine the criteria for a certain surface load W conditions, the wall of the maximum deflection y does not exceed L / 240; The maximum deformation can not be greater than the L / 240 well system under the 200Pa uniform load. The wind load is superimposed and the uniform load will become larger

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- My advice is not to do on wooden flooring Because the wood floor is flexible. The The It is best to finish the wall, and then restore the floor Just personal opinion for reference only

- Q: Light steel keel partition wall construction process is what

- Light steel keel partition wall - → installation of the door hole box - → installation along the top keel and along the keel → vertical keel sub-file - → installation of vertical keel - → installation of horizontal keel card - → installation panel - Sewing practice - → face layer putty paint (or paint).

- Q: How to construct double - sided double gypsum board partition wall

- Line: according to the design and construction plans, in accordance with the keel width of the elastic line, has been done on the ground or ridge to release the wall position line, door and window openings border line, and put the top, wall keel position edge. To cover the panel of the long, wide sub-file, to ensure that the keel position is correct. Heaven and earth keel installation, along the ball line fixed top, to keel, fixed point spacing should not be greater than 600mm, keel docking should remain straight. Fixed keel keel, keel the end should be fixed, fixed should be solid. Wall, column edge keel with nails or wood screws and walls, column fixed, nail distance of 1000mm.

- Q: Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Wood keel is best used, one is poor fire, the second is easy to produce pests, and now the ceiling are gradually replaced by light steel keel keel.

- Q: How to do woodworking partition wall, with door

- Wooden skeleton should use specifications for 40 mm × 70 mm red, from pine. The spacing of the keel should take into account the size of the panel, usually between 450 and 600 mm If there is a door, both sides should establish a vertical keel. The dragon keel should be connected with the lordel open rod, the window on the bottom and the top of the door should be installed along the horizontal keel installed along the ground, along the top wood Leng, the corners should be stretched into the brick at least l20 mm, To ensure that the partition wall and the original structure of the wall connected firmly.

- Q: What is the relationship between the base board and the liner, whether the keel is between the two layers? Such as light in the wall to do soft package, the basic board and liner how to connect?

- General light wall rarely used to fix things, if the drawings are so barely designed to do so.

- Q: Light steel keel wall cheap or cheap red brick

- Of course, is the light steel keel, probably in 70 a square, wall, then 12 of the wall art manual brick is 80, double-sided batch of 30, is 110!

- Q: Shanghai Light Steel keel ceiling Shanghai plant decoration office building decoration light steel keel ceiling wall

- Effective space division The internal space of the plant is mainly divided by the operator according to their actual use requirements to make reasonable use of space, if the plant has a large number of equipment, it is not appropriate to set too much partition and partition, as far as possible to the ground color or with some Color identification to the division of the region, with the identification of the area to avoid too much color, so not only the regional division is not obvious also feel dizzy, and some plants can be clearly divided into the equipment area and office area, such a plan It is now more common because it is easy to manage. Then in the design of such a plant must master the data and the close combination of space, but also take into account the equipment area and the working area of the work area is smooth and dust, noise interference.

Send your message to us

Galvanized stud for gypsum drywall metal stud and track

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords