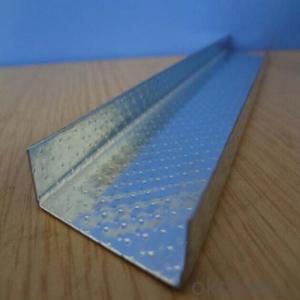

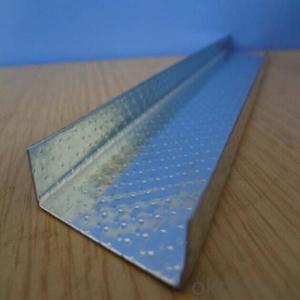

Galvanized Metal Stud and Track for Drywall Steel Light Frame

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 550000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Item name: metal stud

Thickness:0.4-0.8mm

Surface:Zinc Galvanized

Packing: Clear tape, 10pcs/bundle

main channel Technicology:adopting high-grade quality hot-dipped galvanized steel,The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common product

Material

Galvanised steel

Zine Coated Level

60~270 g/m2 (depends on the customer's request

Thickness

0.35~1.20mm

Length:

2000mm, 2700mm, 2800mm, 2900mm, 3000mm, 3600mm

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6, commercial building

Advantages and Features:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6. We can supply you the products based on your specific requirements

Other Products Available:

38 light steel main channel,50 light steel main channel,60 light steel main channel,75 stud,100 stud,.50 track,75 track,100 track.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q: How to install damping sound insulation felt

- 1, along the wall laying sound insulation felt, seam at the pressure seam processing; ???? 2, the installation of vibration keel, wedge around 600mm; keel gap filled with cotton; ???? 3, vibration-proof keel installed on the noise board (two-layer board clip insulation felt, sheet and sound insulation stitch treatment)

- Q: Light steel keel wall to withstand the number of wind load

- Light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, Interior decoration, ceiling and other places.

- Q: Light steel keel wall how to install glass door

- In the cut off, with 20 * 20 or 25 * 25 galvanized iron pipe welded into the design of the size of the box, in the ground, the top of the fixed between the fixed door on both sides of the vertical frame, and then the height of the door plus the same box , Welding beam fixed to the spring on the shaft. ??????? This is to consider the glass door in the abnormal switch will have a huge lateral force, resulting in the door axis prone to displacement.

- Q: Lightweight wallboard light steel keel how to construction

- Damp room and steel plate plaster wall, light partition board keel spacing should not be greater than hundreds of millimeters, the installation of supporting keel, the support card should be installed in the direction of the vertical keel opening, partition wall card should be four hundred To six hundred millimeters, from the keel at both ends of the distance should be twenty to twenty five millimeters, should be fixed according to the location of the ball along the edge, along the keel and border keel, keel line should be coincident with the line.

- Q: Light steel keel wall to remove the price

- Fixed price: the state has a demolition quota, but the price is very low, generally can not afford to be fixed. Now some parts of the decoration quota also have to remove the sub-head, slightly higher than the demolition quota, but no profit.

- Q: Light steel keel wall can be installed sliding door

- How can not press ah. It is estimated that you are afraid of wood that you fooled you And your door is too big to shrink it. The normal door is 800. Get so much useless. Now the light steel keel wall is too much. How can we press the door.

- Q: Decoration decoration works Light steel keel wall, layer 4 meters high thickness What are the requirements? There is no specific specification?

- 1 enhances the integrity, stability and shock resistance of the partition The construction of the law in the ridge before the construction of the ground keel fixed screw and attached to the wall of the fixed support frame in place in the concrete floor, and with the wall to the ridge poured into one, changing the structure of the connection, enhanced Wall integrity, stability and shock resistance. 2 effective prevention of keel deformation and wall panel cracking and other quality problems This method can increase the rigidity of the keel on both sides of the door and the wall pendulum by increasing the steel way to prevent the deformation of the keel system due to the external force. The installation of the fixed and cantilevered structure of the steel member wall, The ridge production, are completed once, changed the wall after the completion of the installation of the toilet or wall equipment, the construction of the cantilevered structure of the platform, effectively control the wall panel cracks and other quality problems. 3 sound insulation and fire effects Embedded in the ridge of the fixed support steel components of the dislocation of the installation, in the world keel and roof and ridge between the border keel and structural walls paved between the fire noise cotton, and sealed with fire sealant, and 100 ㎜ thick gypsum board partition system sound insulation performance equivalent to the traditional 240 mm brick wall effect, reduce the amplitude, enhance the light steel keel wall insulation and fire effects.

- Q: Light steel keel gypsum board partition should pay attention to what quality problems

- 1, contact with the stability of the keel through the keel when the wall height of not more than 3m can be set to a wall height of 3-5m should be set up two, more than 5m should be set to 3. 2, light steel keel gypsum board partition wall should be done to the structure board. 3, for the sound insulation requirements of the partition, should be along the top keel and along the keel and the main structure of the junction, the pad with long sound insulation tape, and in the gypsum board and the main structure of the embedded sealant, Fill 50mm thick glass wool.

- Q: Light steel keel wall how much money a square

- Is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, railway stations, Theater, shopping malls, factories, office buildings, old building renovation, interior decoration, roof and other places.

- Q: Shanghai Light Steel keel ceiling Shanghai plant decoration office building decoration light steel keel ceiling wall

- Focus on the ground material, the first floor of the plant decoration if the ground, a lot of plant floor decoration is not required to carry the load, then you can consider using some inexpensive decorative materials, such as terrazzo or cement flooring to do the plant floor decoration materials, Decoration to consider anti-static, then we should choose anti-static floor or anti-epoxy floor, etc. as the preferred material for the ground, there are plant floor decoration needs to load the ground, then we must do concrete in the ground floor, Concrete is divided into commercial concrete and soil concrete two, the former cost slightly higher but the quality is stable, the latter price lower quality in general, and then in the concrete base and then lay the other texture is more hard stone finishes can be.

Send your message to us

Galvanized Metal Stud and Track for Drywall Steel Light Frame

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 550000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords