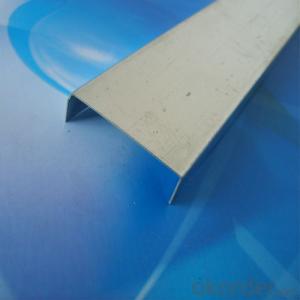

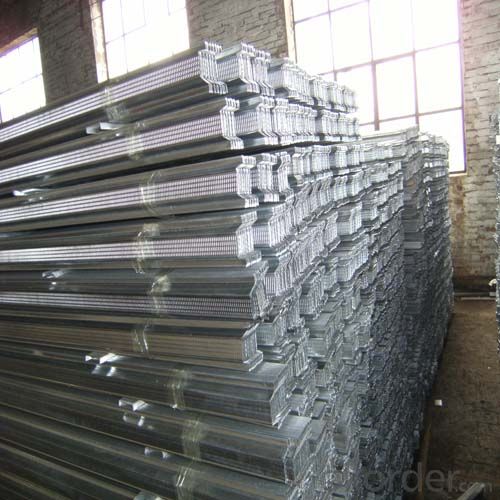

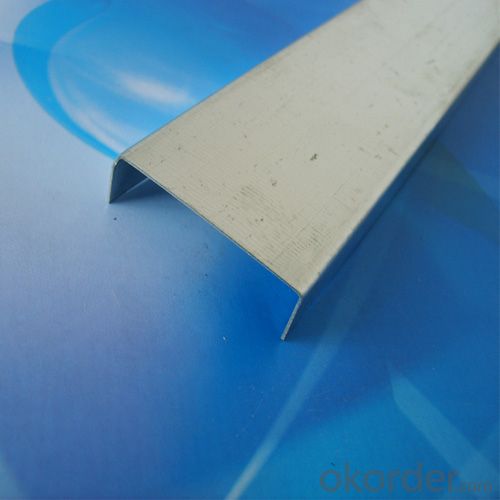

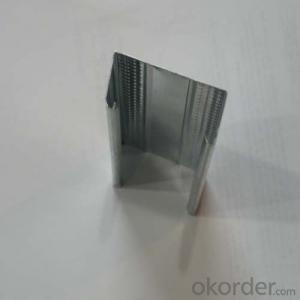

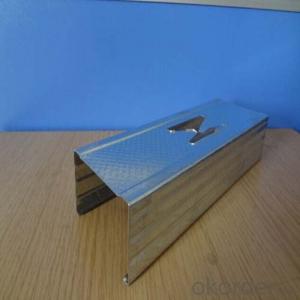

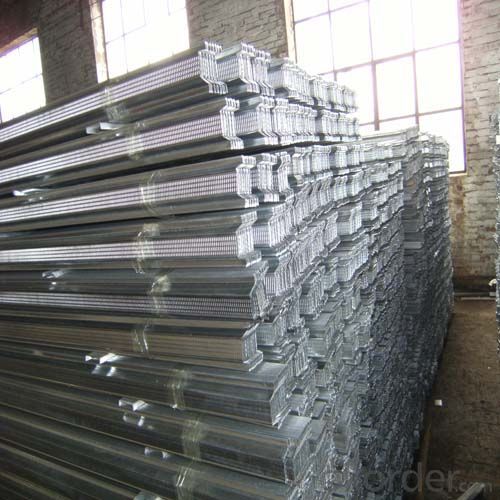

Drywall Metal Stud Galvanized Steel Profiles for Gypsum Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drywall Metal Profile

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

HUILON Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with HUILON magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

Item | Specification (mm) | |

Width | Height | |

V channel | 30/38 | |

Main channel | 38 | 10/12/14 |

Main channel | 50 | 12/15 |

Cross channel | 50 | 15/17/19 |

Cross channel | 60 | 27 |

Cross channel | 38 | 27 |

Furring channel | 35 | 22 |

U angle | 29 | 24/29 |

L angle | 22-35 | |

Track /Horizontal Channel | QU/UW | 50/75/100x35/40/50x0.45mm |

Stud/Vertical Channel | QC/CW | 50/75/100x35/40/50x0.45mm |

Omega Furring Channel | Ω | 35x22x12/13mm |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

Product Overviews

- Q: I was not a tool in the category, or else I got myself!

- I think you do so sound insulation is not the middle of the need to add sound insulation materials. There are many kinds, such as noise insulation cotton class. The more types of composite materials, the more layers, the sound and sound effects the best. It is best to have sound and sound effects have to reduce the sound of the rebound.

- Q: Who used the light steel keel gypsum board to do the wall?

- Not compare province, province, then you buy bricks more province, just better installed than brick light

- Q: Can my light steel keel ceiling withstand the weight?

- To be honest, the thickness of light steel is not visible, and even your different specifications are difficult to identify together. If the figure shown on the release of these things did not occur under the deformation of light steel, it should be no problem

- Q: PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Each corners above the U-slot, this is the use of the buckle board. Light steel keel sub-station dragon and Wolong. Wolong before the installation of the first hammer with a hammer, playing wooden needle, and Wolong fixed, and then install the station dragon, and clamp with a good fit.

- Q: Light steel keel wall and wood which low cost

- Should be a wooden keel, the general family decoration with a wooden keel on it, wood keel cost is low, to meet the family use, light steel keel cost high, but high strength. It is recommended to use wood keel

- Q: Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- Yes, according to the provisions of the standard fixed light steel keel, glass fixed hole, to ensure that the glass transparent and clean, surrounded by transparent glass glue. In the space can be added to the items and so on

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- Do of course But I suggest do not do it! You do not want to move the floor, you put the floor cut off the partition of the piece. Directly to the disadvantages: 1: wooden floor flexible, partition instability. 2: you are not bad when the wall and the floor shut. 3: sound insulation is certainly worse

- Q: Light steel keel gypsum board partition wall brush black latex paint, I would like to change the brush blue latex paint, how to deal with grassroots?

- I am a decoration worker, painter, there are a few details you need to add 1, before the black latex paint is how long to sit? 2, there is no grass-roots off, loose phenomenon? 3, need to transform the home improvement? Or tooling? Because each has a processing method? Need to be added to determine your home to change how to deal with the grassroots, gypsum board in addition to the degree of solidarity you can rest assured that the situation is not damp its structure is still very high!

- Q: Light steel keel wall how much money a square

- Is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, railway stations, Theater, shopping malls, factories, office buildings, old building renovation, interior decoration, roof and other places.

- Q: 9 + 9 double gypsum board is what it means

- Gypsum board is a kind of material made of building gypsum as the main raw material. It is a light weight, high strength, thinner thickness, easy processing and insulation and fire insulation and other properties of better building materials, is currently focused on the development of one of the new lightweight sheet. Gypsum board has been widely used in residential, office buildings, shops, hotels and industrial plants and other buildings within the wall, wall panels (instead of wall plaster layer), ceilings, sound-absorbing panels, ground floor boards and the Such as decorative plates. Gypsum board gypsum board (divided into ordinary gypsum board (commonly used), fiber gypsum board, gypsum decorative plate "interpretation") it to gypsum as the main material, adding fiber, adhesive, modifier, Dry from. With fire, noise, heat, light, high strength, low shrinkage and other characteristics and good stability, not aging, anti-moth, available nails, saws, planing, sticky and other methods of construction.

Send your message to us

Drywall Metal Stud Galvanized Steel Profiles for Gypsum Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords