Metal Profile Stud Track For Drywall Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

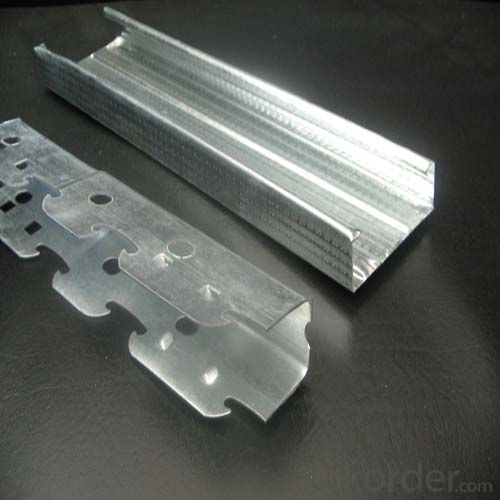

drywall partition metal stud profiles

1.Zinc Galvanized&Snowflakes

2.High quality hot-dipped galvanized steel coil used

Drywall partition metal stud profiles

Main data

1.Zinc Galvanized&Snowflakes

2.High quality hot-dipped galvanized steel coil used

3.For ceiling and wall part Drywall partition metal stud profiles

Main data

1.Zinc Galvanized&Snowflakes

2.High quality hot-dipped galvanized steel coil used

3.For ceiling and wall partition

4.Thichness:0.3mm-0.8mm

5.Length:3mm in common size ition

4.Thichness:0.3mm-0.8mm

5.Length:3mm in common size

6.Color:Silver white

7.Shap:U and C shap

8.Used with paper faced gypsum board or other products

Introduction

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling. Ceiling keel and wall channel has light-weight, high-intensity, good-antisepsis and other advantages. They mainly match to paperbacked plasterboard and other goods, also the other plates such as GRC, FT and so on.

Advantages and Features:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

3.Image

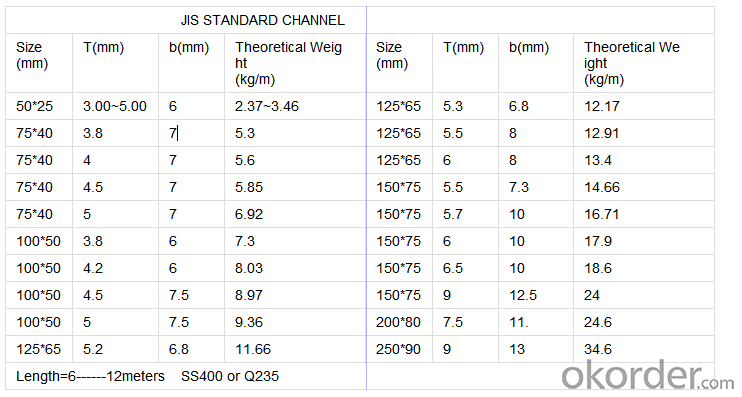

4.Detailed Specification

5.FAQ

Quality inspection procedure

1 At Pennon,10% employees are QC/QA workers.

2 Including Random-checks and sample-checks

3 Qualified rate is higher than 98%

4 We have five strict QC processes including incoming materials QC, IPQC (in process QC on patrol), LQC (line QC), FQC (final product QC) and OQC (output QC before shipping).

Payment

- Q: Light steel keel wall to withstand the number of wind load

- According to the thickness of the keel, the height of the partition, supporting the keel, supporting the card is complete, the wall is also about 200 ~ 600Pa wind pressure is not obvious deformation.

- Q: Light steel keel gypsum board wall height is how to determine

- There is no specific rigid provisions, the specific height according to the actual situation to the scene. Light steel wall commonly used for each root is 3 meters long, if the actual height beyond too much, you can order.

- Q: 6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- It is best to do the top, or else do the ceiling to do the wall can also be done,

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- Each brand installation and installation methods and characteristics will be different, I will take the Nexu light steel keel brief description of the next.

- Q: Light steel keel gypsum board partition should pay attention to what quality problems

- For the wall (or the top wall of the building), the distance between the vertical keel shall not be greater than 400mm, the distance between the transverse keel shall not be more than 600mm, and the fire gypsum board shall be used. Fixed, the upper edge of the gypsum board fixed on the top with the keel, the board from the floor should be greater than 20mm, and fire sealant with solid.

- Q: Light steel keel wall gypsum board seams how to deal with? Including smallpox

- White is the hook agent, the tape is anti-crack tape, paste the back after the brush can prevent the latex paint.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- Gypsum board at the end of the seams should be open groove, easy to capping processing. Gypsum board edge joints should be in accordance with the provisions of the process.

- Q: In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- First do a good wall partition 2.8 high, 6 meters high in the top if it is the roof, then use the boom directly pull down

- Q: What is the pros and cons of a brick or a gypsum board?

- Wall, then the sound is very important, otherwise the side of the talk there all heard, this wall is very embarrassing. Light gypsum board, of course, can not be soundproof, the key is to choose the appropriate sound insulation cotton, and now people are more popular in the interior decoration is the gradient of sound-absorbing cotton, from environmental protection, fire, sound-absorbing efficiency and other considerations, gradient sound-absorbing cotton are present Home, office decoration more appropriate, such as the larger domestic conference center are using this sound insulation material.

- Q: Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Benzene board and extruded board can be, are more suitable for home improvement. I do with the noise is extruded board than the benzene board sound insulation is also very good environmental protection

Send your message to us

Metal Profile Stud Track For Drywall Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords