Stud & Track for Drywall System Stud & Track for Drywall System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge

etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

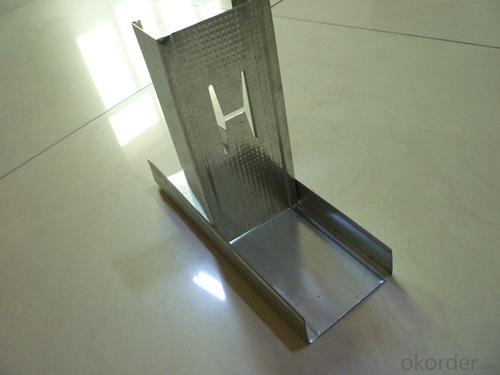

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

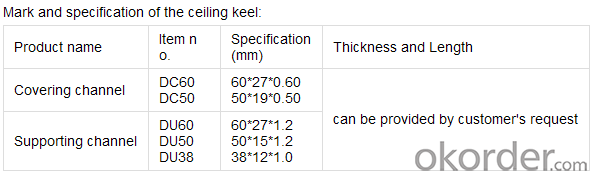

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q: Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- Light steel keel (generally with gypsum board) wall lightweight, easy construction, low cost, a large number of indoor partitions,

- Q: How to install damping sound insulation felt

- 1, along the wall laying sound insulation felt, seam at the pressure seam processing; ???? 2, the installation of vibration keel, wedge around 600mm; keel gap filled with cotton; ???? 3, vibration-proof keel installed on the noise board (two-layer board clip insulation felt, sheet and sound insulation stitch treatment)

- Q: Shanghai light steel keel ceiling, wall quotes

- Not material money, the wall is generally single to 12 to 18 yuan per square meter, double 18 to 24 yuan per square meter. Ceiling 20 yuan per square meter

- Q: Light steel keel gypsum board wall height is how to determine

- D = <l 240 Parameter Description: d: Maximum deformation of the component under uniform load, unit mmq: Uniform load, unit Pa, test In the composition of the material, the cross-sectional nature of the wall stiffness coefficient: EI value of the test to determine the length of the wall The use of 15mm plate instead of 12.5mm plate, the wall stiffness EI can be increased by 33% 2. The keel spacing from 600mm to 400mm, wall EI value increased by 50% 3. The keel spacing reduced from 400mm to 300mm, the wall EI value increased by 50% 4. keel on the wall than the non-buckle wall, EI value increased by 60% 5. Use type I keel than the use of C-keel, EI value increased by at least 100%. The effect of thickness on the EI value is very small relative to several other factors, EI is called bending stiffness, 75 keel spacing is 400, double-sided single layer 12mm gypsum board wall EI = 4.6 × 1010 according to the actual test EI value of the structural partition system: (unit: N.mm2, 1010)

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- Well, I think so, I found two companies were quoted, the price is almost, but the listed materials are not the same.

- Q: Is it possible to use a hollow brick or a 95 brick?

- Decoration in the practice of a lot of walls, in addition to brick, you can also use light steel keel plus gypsum board practice and so on, the key is to look at the area of the wall surrounded by how much, in what position, use, etc., then To decide the wall of the program.

- Q: Light steel keel wall can be installed sliding door

- 940 door to install the sliding door a bit small, open only less than 500 after the space, I suggest you install the folding door

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- You said the mineral wool board and gypsum board can not be used because they are not waterproof tide will be deformed Recommended ceiling with PPC or aluminum gusset plate is to do with the wall with calcium silicate board is the cement board on the line waterproof paint with a little better is no problem

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board partition can be said that the construction industry is now the forefront of science and technology, originated in Japan, because Japan is earthquake-prone countries, the seismic performance of the wall is very particular about, and high prices in Japan, Too high, so the house designers have invented the light steel keel inorganic composite board partition. Light steel keel inorganic composite board wall composed of light steel keel and double-sided inorganic composite panels, up and down wrapped sound insulation pad, with a solid and reliable, practical and practical features, and the thickness of only about 175px, 300px than the average wall thin. One inorganic composite board for the new inorganic composite materials, environmentally friendly materials, non-toxic and tasteless, excellent physical properties. It is composed of silicon, calcium and magnesium composite cementitious materials, and is applied by polymer composite technology. With fire-retardant, heat insulation, waterproof, waterproof, pest control, mildew, light, high strength, environmental protection and energy saving, construction fast, easy to finishes and so on. Light steel keel and inorganic composite board composed of light steel keel inorganic composite board partition wall as a partition, with strong earthquake resistance, sound insulation, easy to dismantle modification and space saving and other characteristics, a market will be favorable by the Japanese market , Has been widely used in foreign countries.

- Q: 9 + 9 double gypsum board is what it means

- Gypsum board is a kind of material made of building gypsum as the main raw material. It is a light weight, high strength, thinner thickness, easy processing and insulation and fire insulation and other properties of better building materials, is currently focused on the development of one of the new lightweight sheet. Gypsum board has been widely used in residential, office buildings, shops, hotels and industrial plants and other buildings within the wall, wall panels (instead of wall plaster layer), ceilings, sound-absorbing panels, ground floor boards and the Such as decorative plates. Gypsum board gypsum board (divided into ordinary gypsum board (commonly used), fiber gypsum board, gypsum decorative plate "interpretation") it to gypsum as the main material, adding fiber, adhesive, modifier, Dry from. With fire, noise, heat, light, high strength, low shrinkage and other characteristics and good stability, not aging, anti-moth, available nails, saws, planing, sticky and other methods of construction.

Send your message to us

Stud & Track for Drywall System Stud & Track for Drywall System

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords