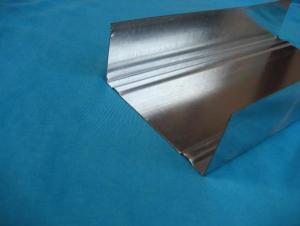

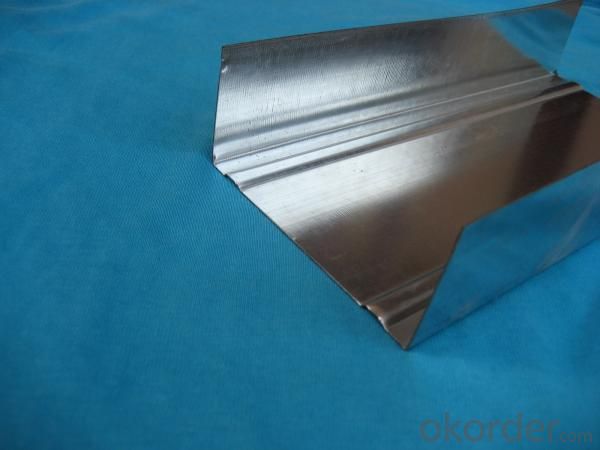

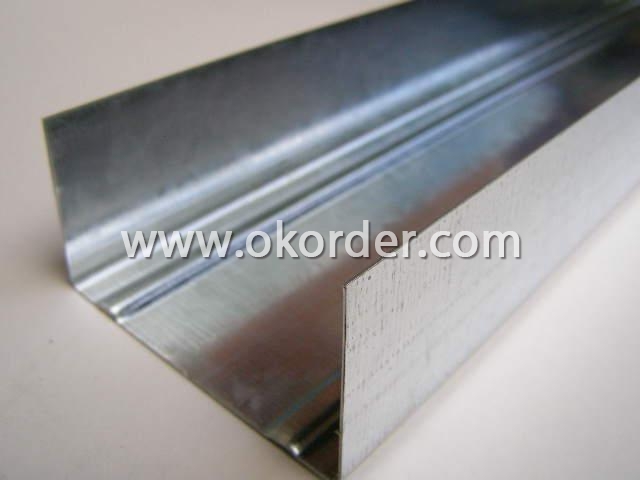

Drywall Steel Profiles for Decoration

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Container m

- Supply Capability:

- 30 Containers/Month m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: 0.40~1mm

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q: 75 series of light steel keel wall double-sided double-layer 12 thick plaster board filled with sound insulation noise can reach the number of decibels

- Single-layer gypsum board sound insulation is poor, for example: 12mm thick, surface density of 10Kg / m 2 or so of paper gypsum board standard weighting noise C = 29dB. Even if the four layers of such gypsum board stack and together in the sound insulation on the theoretical Rw can only reach 41 dB. If the paper gypsum board made of double-wall structure, the sound insulation can be improved. Such as the above four layers of paper gypsum board made 75mm light steel keel double double wall, Rw can reach 44dB. If the cavity is filled with cotton, Rw can be increased to 50dB.

- Q: In Shanghai 75 partition wall light steel keel 0.6 what price now

- Low-grade 3.5-4.5 yuan / m range. Light steel keel, flower head a lot. Side high, the actual thickness, galvanized surface, strip material are very affected price.

- Q: Shanghai light steel keel ceiling, wall quotes

- Not material money, the wall is generally single to 12 to 18 yuan per square meter, double 18 to 24 yuan per square meter. Ceiling 20 yuan per square meter

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- Decorate the wood keel can be, and then use the integrated wall covered up on it. The other keels are too much trouble and time.

- Q: Light steel keel wall can be installed sliding door

- How can not press ah. It is estimated that you are afraid of wood that you fooled you And your door is too big to shrink it. The normal door is 800. Get so much useless. Now the light steel keel wall is too much. How can we press the door.

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board partition is a high toughness material, compared to the traditional partition, better shock resistance. In the simulation of super 8 earthquake experiment, the traditional block wall has long been decomposed collapse, but the light steel keel inorganic composite board wall is still solid and reliable, showing its seismic capacity far more than the traditional wall, which is light steel Keel inorganic composite board partition in Japan widely used reasons, security is the primary consideration of residential construction factors.

- Q: Light steel keel partition wall how to paint

- Light steel keel structure, to find the location of the keel, use a long self-tapping screws, forced into the screw. So that it can be stable.

- Q: 100 light steel keel 9.5mm thick gypsum board double double-sided partition three times, three times latex paint.

- The cost can not say ah, the material price is not the same ah, light steel keel brand and small brand, wall thickness is not the same, the price is not the same Finished putty powder is not different access, generally 0.6 yuan / kg or so; latex paint is not the same price, never less than 10 yuan / kg to 50 yuan / kg have. Rock wool about 10 yuan / m2, not much money auxiliary materials, together have 3 yuan / m2 are not used. Who knows what price to choose ah

- Q: What is the relationship between the base board and the liner, whether the keel is between the two layers? Such as light in the wall to do soft package, the basic board and liner how to connect?

- In the original wall to do single-sided light steel keel wall, blockboard base, the installation of aluminum alloy hanging, and then soft package fixed on the bar.

- Q: Gypsum board wall is generally done to the height of the original roof or do the height of the ceiling?

- Keel to the top, the finishes of the board can not to the top

Send your message to us

Drywall Steel Profiles for Decoration

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Container m

- Supply Capability:

- 30 Containers/Month m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords