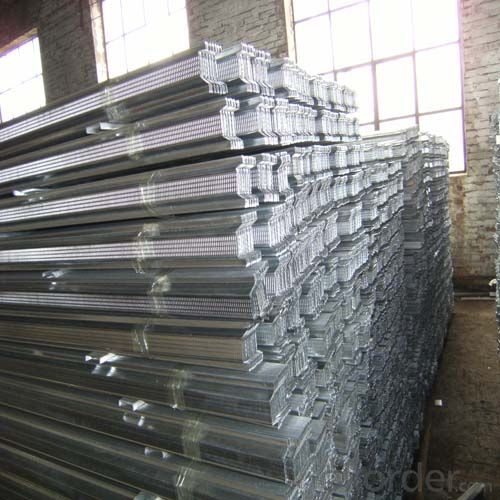

Galvanized Steel Drywall 100 Runner And Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed product description:

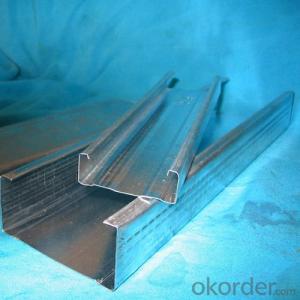

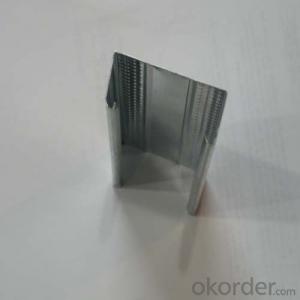

1) Item: W-35, 38 main channal, L angle, Connor Bead, DC-60, U-60, 50 Stud & track, 75 Stud and track, 100 Stud and track, ect.

2) thickness: 0.4-1.0mm

3) Length: 3000mm or dependes on customer's request

4) Zinc coating: 50-220g/m2 (depends on the customer's request)

5) Size as fellow form: (Width*Height*Thickness)

Product apply in: Mid East , Rusia, Europ, South America, Africa

Certificate for products:CE,stand :EN13964; ISO9001-2000

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Trade Shows

Main Markets: | 15.60% Southeast Asia |

13.2% Eastern Europe | |

12.3% Eastern Asia | |

12.00% North America | |

11.80% Mid East | |

10.8% Africa | |

9.50% South America | |

7.60% Oceania | |

6.70% Western Europe | |

Total Annual Sales Volume: | US$10 Million - US$50 Million |

Export Percentage | 51% - 60% |

Advantages and features:

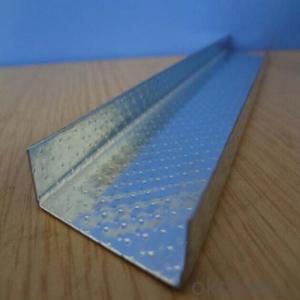

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: How to install damping sound insulation felt

- Keel on the installation of poly-mao acoustic insulation board (two-layer board folder sound insulation felt, sheet and sound insulation stitching treatment), noise board between the seams and sound insulation board and roof, floor joints for construction sealant seal.

- Q: 75 light steel keel wall to do 6m high, need reinforcement? How to strengthen?

- Must do 75 keel, it is recommended to add angle iron or square tube reinforcement, do not forget to do heart keel

- Q: Light steel keel gypsum board wall height is how to determine

- D = <l 240 Parameter Description: d: Maximum deformation of the component under uniform load, unit mmq: Uniform load, unit Pa, test In the composition of the material, the cross-sectional nature of the wall stiffness coefficient: EI value of the test to determine the length of the wall The use of 15mm plate instead of 12.5mm plate, the wall stiffness EI can be increased by 33% 2. The keel spacing from 600mm to 400mm, wall EI value increased by 50% 3. The keel spacing reduced from 400mm to 300mm, the wall EI value increased by 50% 4. keel on the wall than the non-buckle wall, EI value increased by 60% 5. Use type I keel than the use of C-keel, EI value increased by at least 100%. The effect of thickness on the EI value is very small relative to several other factors, EI is called bending stiffness, 75 keel spacing is 400, double-sided single layer 12mm gypsum board wall EI = 4.6 × 1010 according to the actual test EI value of the structural partition system: (unit: N.mm2, 1010)

- Q: Shanghai light steel keel ceiling wall how much labor costs?

- Do not know how much of your area may be a little expensive point of the ceiling 10 yuan / square wall 80 / side less expensive to the point is not the same everywhere, roughly in the 20 to 25 or so labor price.

- Q: Waterproof gypsum board for toilet partition and paste tile installation steps?

- Bathroom wall on the calcium silicate board filled with less than 3CM steel mesh; fixed with a code nail gun; and then use 1: 3 of the cement mortar smear 2-3CM thick. After leveling the hair according to the normal process of paving wall.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- Gypsum board at the end of the seams should be open groove, easy to capping processing. Gypsum board edge joints should be in accordance with the provisions of the process.

- Q: Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- And traditional wooden keel wall for comparison? Basically, the framework is different, flatness is different, the cost is different.

- Q: How to construct double - sided double gypsum board partition wall

- Installation of vertical keel, light steel vertical keel. Keel must be vertical, vertical keel inserted at both ends along the top keel and along the keel, adjust the vertical and positioning accuracy, with a core pulling rivets fixed.

- Q: Light steel keel installed security door how loaded really

- It is recommended to install two square steel pipes vertically and fixed on the concrete floor and floor. The security door is mounted on the square steel pipe

- Q: How to do woodworking partition wall, with door

- Wood keel partition wall inspection standards: the size of the partition is correct, the material specifications are consistent: the wall straight, smooth, corner of the orthogonally close F along the ground, along the top of the wood and the edge of the wall, Firm and straight. Check the partition wall, with 2 m ruler detection, the surface roughness error is less than 2 mm, vertical plane tolerance is less than 3 mm, seam height difference is less than 0.5 mm.

Send your message to us

Galvanized Steel Drywall 100 Runner And Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords