Drywall Partition of Galvanized Structural Steel Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

1. False Ceilings T Bar System in 24 mm and 15 mm width. (38 mm and 32 mm systems)

2. False Ceilings Furring Bar system

3. Adjustable Hanger Rods systems for False Ceilings

4. Drywall TRACKS AND STUDS in 50 mm, 65 mm, 75 mm, 90 mm and 100 mm widths.

5. Aluminium Metal Ceilings in Strips for Inetrior and Exterior applications (75 mm, 150 mm)

Beside the Building Products, we also export tea with high quality and best price.

6. metal channel/metal profile/steel profile raw material is high quality cold roll steel coil, strictly quality control make sure high quality product.

7. metal channel/metal profile/steel profilezinc coating can be 80-300g/m2.

8. Warm sales in Middle East , Africa and America , which have enjoyed an excellent reputation with high quality and services.

9. The specification can as customer requirments.

Product Type:

1. Building Products

2. Tea

Specification

Available in two thickness sizesNo 24 with thickness of .55 mmNo 26 with a thickness of 0.45 mmSection C & U Stud for both thickness is equal.

Standard | AISI,ASTM,BS,DIN,JIS |

Type | Galvanized steel, Aluminium, stainless steel ,carbon steel etc |

Place of Origin | China (Mainland) |

Technique | Cold rolled, hot rolled |

Surface Treatment | Hot dipped galvanized, power coating, color coating etc |

Application | Structural use, roofing, industry,construction etc |

Length | As your requirement |

Thickness | 0.4-0.8mm |

Zinc coating | 40--300 g/m2 |

MOQ | 1000pcs |

Delivery time | 20-25 days after receive your deposit |

Feature

(1) Ceiling solid structure, good safety performance

(2) Frame and light weight

(3) No rust, no corrosion, life is very long

(4) It can variety of shapes roofs

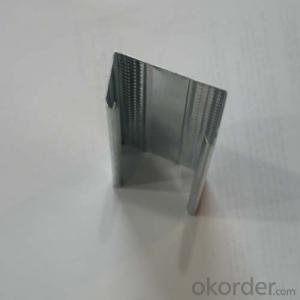

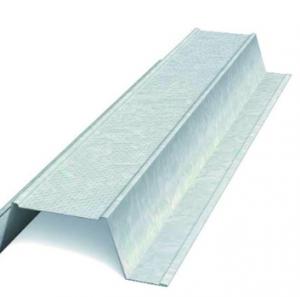

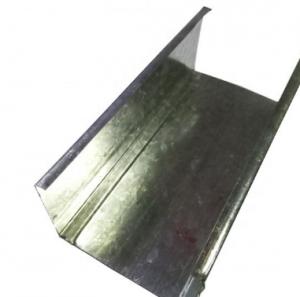

Product Show

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Light steel keel wall to withstand the number of wind load

- This test really no standard, the general wall is not the index of wind pressure, mechanics is also the most test is the impact and static load test, personal feeling according to the thickness of the keel, the height of the wall, supporting the keel, supporting card Whether it is complete, wall pressure against the wind is almost 200 ~ 600Pa no obvious deformation.

- Q: Light steel keel cut off the keel and the ground with what fixed?

- Expansion bolt or pad on a layer of blockboard (brush fire anti-corrosion coating) with 50 steel row nail directly on the ground

- Q: Shanghai light steel keel ceiling, wall quotes

- Not material money, the wall is generally single to 12 to 18 yuan per square meter, double 18 to 24 yuan per square meter. Ceiling 20 yuan per square meter

- Q: Lightweight wallboard light steel keel how to construction

- Wood keel installation to keel cross-sectional area and vertical and horizontal spacing should meet the design requirements, lightweight partition plate skeleton horizontal, vertical keel should be used to open half a tenon plus glue, plus nail connection. Before installing the panel, the keel should be fire-treated, the wall should be in accordance with the design requirements, along the ground, the wall top wall and the width of the wall line, the width of the wall should be consistent with the thickness of the wall should be clear, Accurate, the installation of vertical keel should be vertical, keel spacing should meet the design requirements.

- Q: Lightproof wall how to fire

- And light steel keel installation door is the same light steel keel door frame after doing the light steel keel and then do a fixed two-layer woodworking board as a door cover and then the fire door fixed in the woodworking board or in the light steel keel fixed channel steel Made the door sets and then fixed fire doors or not the first gypsum board in the light steel keel on the back of the fixed fire door or with a channel or angle or simply use a wooden fire door

- Q: The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- How to get someone else, please eat a meal, or simply do not thousands of dollars that deposit

- Q: PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Plastic buckle the corners of the line, the normal practice for the eye plug plug stopper, with self-tapping screws fixed. Plastic buckle has its own slot, in the male slot with self-tapping screws fixed on the keel. Light steel keel gypsum board wall, with the heaven and earth keel to the ground in the ground punching cork with nails fixed; Tianlong the same.

- Q: How to construct double - sided double gypsum board partition wall

- Vertical keel sub-file: According to the location of the wall defense door openings, in the installation of the top keel, according to the specifications of the panel panel width, sub-file size 450mm, less than the modulus of the file should avoid the first box Plate position, so that the edge of the gypsum cover panel is not out of the box. Installation of horizontal card keel: According to the design requirements, wall height greater than 3m should be added to the horizontal card retaining keel, mining core pulling rivets or screws tied to fixed

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board partition is a high toughness material, compared to the traditional partition, better shock resistance. In the simulation of super 8 earthquake experiment, the traditional block wall has long been decomposed collapse, but the light steel keel inorganic composite board wall is still solid and reliable, showing its seismic capacity far more than the traditional wall, which is light steel Keel inorganic composite board partition in Japan widely used reasons, security is the primary consideration of residential construction factors.

- Q: Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Benzene board and extruded board can be, are more suitable for home improvement. I do with the noise is extruded board than the benzene board sound insulation is also very good environmental protection

Send your message to us

Drywall Partition of Galvanized Structural Steel Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords