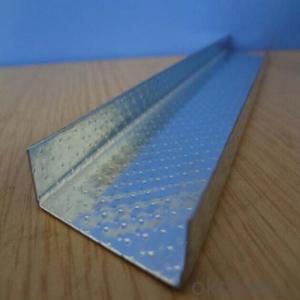

Galvanized metal steel stud and tracks for partition drywall and ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized metal steel stud and tracks for partition drywall and ceiling

Instruction

Drywall Metal Profile

Drywall ceiling Channel is galvanized metal structure used in non-bearing partition systerm .

Drywall steel frame system is a popular way to be used to divide the space,especially using in commercial buildings.

Drywall Steel Frame System is made of galvanized steel sheet with good rust-Proof function.A variety of frames are ready for customers' demands and designers' choice for different purposes and places. One of our merits is the special hole for channel on C-stud in per 6Ocm which is easy for workers to install the electric lines and water tubes.CH and IH type of studs are the special type we developed to solve the hard work situation in elevator ventilator and offer a better protection of workers' safety.

Our dry wall steel frames are covered with magnesium fireproof boards and fulfilled with material which is heat insulation and noise-proof mineral wool between two layers of boards. It will create a better living environment than the traditional building materials.

Suspension ceiling structure,Galvanized metal structure which is the vertical metal framework used in non-bearing partition system.

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe,

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Galvanized metal steel stud and tracks for partition drywall and ceiling

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa ,

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

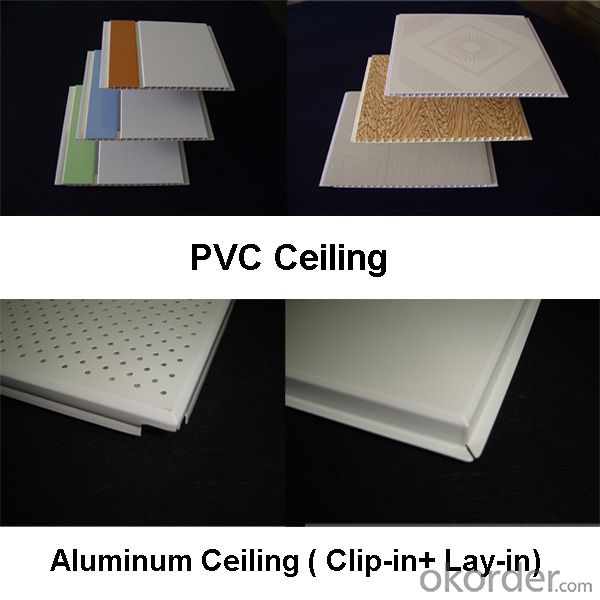

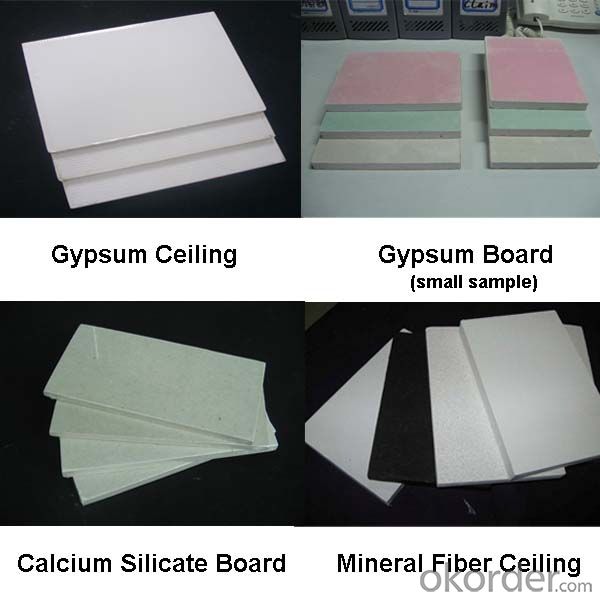

Other products we supply:

Galvanized metal steel stud and tracks for partition drywall and ceiling

- Q: Light steel keel ceiling hanging bar spacing how much?

- 80-100cm or so, the light keel of the main keel and the keel have the quality of good or bad, so the intensity is different, the specific spacing as the case may be

- Q: Light steel keel ceiling and wood keel ceiling What is the difference between ah! Which performance is better, the price difference is different! Ask everyone!

- Home decoration on the process requirements are higher.With the wooden keel to make the framework easy to correct .. so that the ceiling is not easy to deformation in the installation, after all, is the wood due to changes in the weather season, there will be hot up cold shrinkage. When the decoration is generally required for the wooden keel frame fixed. Fixed in the ceiling keel should be every 60 cm should play an expansion screw. The next well-shaped frame should be bayonet handle, gun nail fixed. Well shape frame every 30 cm The wood keel is a flammable material, no fire .. at the price of wood keel than light steel keel is higher .. now wood keel one meter at least 2 yuan. , Light steel keel need to be placed side by side .. Light steel keel because the specifications are too long, not suitable for use in the family, because the home decoration is not like a tooling decoration ceiling is a large area with light steel keel is drawn, The family can not draw, but also a reason is the family ceiling because the area is only part of the use of light steel keel is not to do. Must be the wooden keel frame can be .. so in the home decoration with wood keel is the best choice.

- Q: Light steel keel ceiling cad chart

- There is a special light steel keel construction of the chart to sell, you can buy a set, only tens of dollars, inside the various forms of light steel keel ceiling, partitions have detailed construction techniques and regulatory requirements

- Q: Is the thickness of the light steel keel related to the height of the ceiling?

- Light steel keel thickness has nothing to do with the height of the ceiling, and the span of the relationship between the ceiling, span, light steel keel thickness is slightly thicker.

- Q: The construction of the lightweight steel keel gypsum board ceiling

- With a large sample can be expressed, draw the main keel, and then draw the vice keel, a few lines that on the line.

- Q: Ceiling light steel keel 50/60 in 60 on behalf of what

- Specifications model ah main keel 50 is 50 × 15 × 1.2 60 is 60 × 27 × 1.2

- Q: For example, the original requirement is 0.9 to 1.0 But actually made a 0.7, Is there any harm?

- Ceiling in the wood keel spacing: 1, light steel keel: keel for the edge of the dragon, the lamp slot position with keel or woodworking board production, there are wood production office to brush fire paint, keel at least 50, spacing 30cm is appropriate, hanging spacing 60-80cm is appropriate, gypsum Between the board and the board to be reserved for 5-8 mm gap, gypsum board self-tapping screws 1-2mm and do anti-embroidered treatment, to be smooth and solid, shaped to be smooth lines; 2, keel: keel at least 3 × 4 or more, spacing 30cm is appropriate, hanging spacing 60-80cm is appropriate, hanging bar is strictly prohibited direct use of wood wedge nail to the top, brush tight fire paint until the keel color can not see the dragon A layer of full-legged rice eucalyptus core after nine on the gypsum board, gypsum board and the board between the people to set aside 5-8mm gap, gypsum board self-tapping screws 1-2mm and do anti-embroidered treatment, to do To the formation of solid, shaped to do smooth lines; 3, aluminum buckle board: strict requirements level, light steel keel bayonet to be aligned, keel spacing of 50 or less, hanging spacing 60-80 cm is appropriate, the board when the hand to light, so as not to press the board, And the contact with the tile is not tight to use the sealant to play tight; 4, aluminum-plastic plate: keel at least 3 × 4 or more, spacing 30 cm is appropriate, hanging spacing 60-80cm is appropriate, brush tight fire paint, keel on a layer of full-legged rice eucalyptus core 9% Adhesive paste aluminum-plastic plate, aluminum-plastic plate between the board to be reserved for 3-4mm gap, prepared to fill other colors play the effect of sub-grid, to be smooth and solid, shaped to do smooth lines, folding The angle can not be broken.

- Q: Attic light steel keel gypsum board ceiling construction drawings how to draw?

- Is the light steel keel plus gypsum board slightly, the plane is the projection plan, draw the steeple on the line;

- Q: Now decoration light steel keel 600X600 mineral wool board (ordinary) ceiling how much money a square meter?

- Package workers a square meter twenty yuan or so, Bao Gong Bao material will be about a square meter 70 yuan,

- Q: Light steel keel ceiling boom and whether the strong electric lines can be common

- I also do this line, is not the supervision is not signed recognition, because the general ceiling are used iron pipe or PVC, although the PVC is insulated but not insurance is not out of line inside the line are strong, if Received a smallpox as a fault is difficult to find the use of the boom can not be unified grounding grounding is also easy to repair these materials in the cost of money should not be the province.

Send your message to us

Galvanized metal steel stud and tracks for partition drywall and ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords