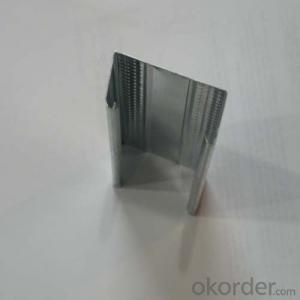

Gypsum Drywall Partition Metal Track and Metal Stud for Wall Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overviews

Introduction:

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

Specification

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Trade Shows

Main Markets: | 15.60% Southeast Asia |

13.2% Eastern Europe | |

12.3% Eastern Asia | |

12.00% North America | |

11.80% Mid East | |

10.8% Africa | |

9.50% South America | |

7.60% Oceania | |

6.70% Western Europe | |

Total Annual Sales Volume: | US$10 Million - US$50 Million |

Export Percentage | 51% - 60% |

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is aIntroduction:

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc..

C metal stud is faced with plasterboard

U metal track is installed along the floor to fix metal stud

- Q: Light steel keel wall to withstand the number of wind load

- Light steel keel is a new type of building materials, with the development of China's modernization, in recent years has been widely used in hotels, terminals, passenger stations, stations, theaters, shopping malls, factories, office buildings, Interior decoration, ceiling and other places.

- Q: The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- With the filling block wall, and the same brick with the nail what is no problem, the weight is not heavy, the thinnest filling block is 120 thick, even the total thickness of double-sided plaster does not exceed 180, or light The partition wall is also the line, faster, but also durable, more than gypsum board wall to spend more, but at least the first nibbling nails are no problem, more durable and reliable, the weight is also light, the normal stay on the trip.

- Q: The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- Can only use the exhibition frame. You may be a mall. Now shopping malls are so, independent to be a exhibition,

- Q: Light steel keel wall waterproof

- The grass on the surface of the gray skin with a knife to remove, with a broom to dust, sand and other debris clean, especially the root, floor drain and drain and other parts to be carefully cleaned. If there is oil, apply wire brush and sandpaper brush off. The base surface must be flat, the depression should be filled with cement putty.

- Q: 6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- Formal practice, must be done to the top, unless it is not the request, nobody tube project, it may not be the top.

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Yes, the gypsum board partition wall is not much weight, far less than the prefabricated board capacity

- Q: How to install light steel keel gypsum board wall

- Light steel keel gypsum board installation should generally be through the following steps: wall line → wall construction → installation along the ground, along the top keel → installation of vertical keel → fixed door and window makeup → installation of the wall side of the gypsum board → install another side of the plaster price → seam processing → wall decoration. 1. Wall line According to the design of the wall, in the ground to release the wall bit line, and the line leads to the ceiling and side walls. 2. Wall construction First on the wall and floor, ground contact parts for cleaning, coated with interface treatment agent together, then pouring C20 concrete wall, the wall surface should be smooth, both sides should be vertical. 3. Install the edge along the top keel Along the ground, along the top keel in place, with the nail fixed, shot nail from the 900mm, the location of the nail should avoid the laying of the tube area. 4. Install the vertical keel According to the determined vertical keel spacing, along the ground, along the top keel on the line drawing line. The vertical keel is arranged by the end of the wall. When the doors and windows are provided with windows and doors, they should be arranged from one side or both sides of the door window. When the last keel from the wall of the size is greater than the provisions of the keel spacing, you must add a keel. The upper and lower ends of the keel should be fixed along with the top, along the keel with rivets or tapping screws.

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- Light steel keel is attached to the gypsum board, it can be seen, the installation of light steel keel spacing is based on the thickness of the gypsum board to decide. Like the 12mm gypsum board, its spacing is 450mm, according to the gypsum board to determine its spacing. Finally, in the adjustment of hanging pieces into the keel inside the appropriate rotation can be consistent.

- Q: Light steel keel partition wall construction process is what

- (1) Pin line, sub-file: in the partition with the upper and lower and the two sides of the matrix at the junction, should be the width of the keel line. Battle clear, accurate location. According to the design requirements, combined with the cover panel of the long and wide sub-file to determine the vertical keel; transverse and additional keel position. (2) for the pillow: when the design requirements, according to the design requirements for the concrete pillow. For the pillow should be supporting mold, bean stone concrete should be pound dense. (3) fixed along the edge, along the keel; along the line position fixed along the edge, along the keel, can be fixed with nails or expansion bolts, fixed point spacing should not be greater than 600mm, keel docking should remain straight.

- Q: How much does it cost to use a light steel keel gypsum board?

- 15 square meters of the wall 15 * 65 = 925 + ordinary door 300 - 400 + installation door hand fee 120 = 1345-1445. But the square is too small, the general companies do not want to do, the fare back and forth have much money.

Send your message to us

Gypsum Drywall Partition Metal Track and Metal Stud for Wall Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords