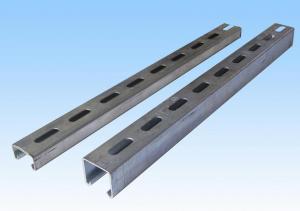

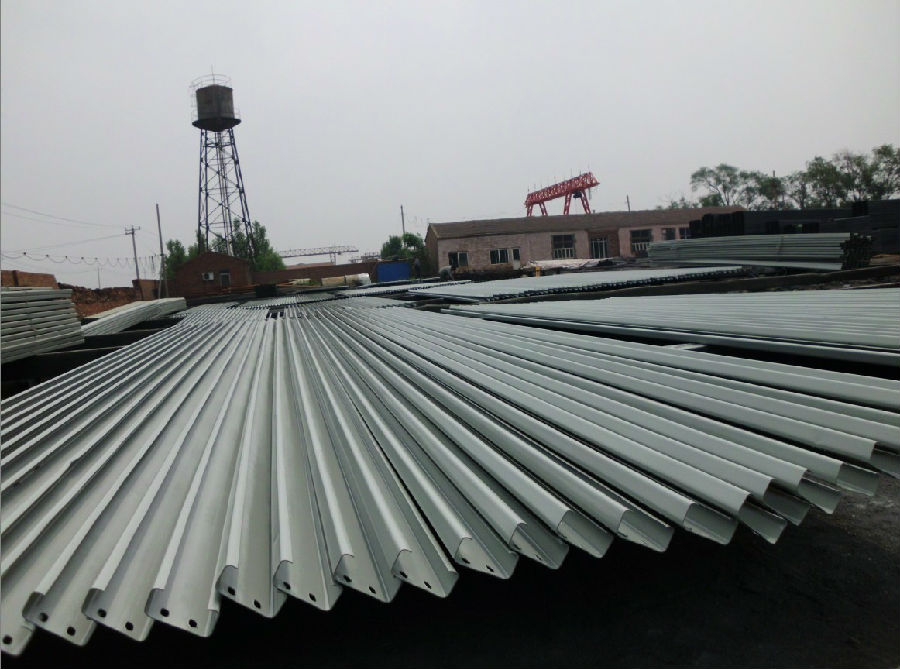

Galvanized Steel C-Channel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Galvanized Steel C-Channels at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Galvanized Steel C-Channels are ideal for structural applications and general fabricating.

Product Advantages:

OKorder's Steel Channels are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (20 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Base Model

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: Q195, Q215, Q235, Q345, SS400

Shape: C-channel

Surface: Painted, galvanized, as per customer request

No. | Dimensions (mm) | No. | Dimensions (mm) |

001 | 80*40*15*1.7 | 015 | 160*70*20*3.0 |

003 | 100*50*20*1.7 | 017 | 180*70*20*3.0 |

004 | 100*50*20*2.0 | 018 | 200*70*20*2.5 |

005 | 100*50*20*2.5 | 019 | 200*70*20*3.0 |

006 | 120*50*20*1.7 | 020 | 220*70*20*2.5 |

007 | 120*50*20*2.0 | 021 | 220*70*20*3.0 |

008 | 120*50*20*2.5 | 022 | 220*75*20*2.5 |

009 | 140*50*20*2.0 | 023 | 220*75*20*3.0 |

010 | 140*50*20*2.5 | 024 | 250*75*20*2.5 |

011 | 140*60*20*2.5 | 025 | 250*75*20*3.0 |

012 | 160*60*20*2.5 | 026 | 280*70*20*2.5 |

013 | 160*60*20*3.0 | 027 | 280*70*20*3.0 |

014 | 160*70*20*2.5 | 028 | 300*75*20*2.5 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do steel channels compare to other structural materials?

- When comparing steel channels to other structural materials, it is evident that they have many advantages. Firstly, steel channels possess incredible strength and a high load-bearing capacity. This enables them to withstand heavy loads and provide exceptional structural support, making them suitable for a wide range of applications such as bridges, buildings, and infrastructure projects. In addition, steel channels exhibit high durability and have a long lifespan. They are resistant to corrosion, rust, and degradation, ensuring their ability to withstand harsh environmental conditions and maintain their integrity over time. This durability makes steel channels a cost-effective option as they require minimal maintenance and replacement. Moreover, steel channels offer great design versatility. They can be easily fabricated and customized to meet specific project requirements. They can be cut, drilled, and shaped into various sizes and lengths, allowing for flexibility in design and construction. This adaptability makes steel channels suitable for both simple and complex structural applications. Furthermore, steel channels possess excellent fire resistance properties. They can endure high temperatures for a longer duration compared to materials like wood or aluminum. This makes them a safer choice for buildings and structures, as they provide additional time for evacuation and minimize the risk of collapse during a fire. Lastly, steel channels are environmentally friendly. They are created from recycled materials and can be recycled at the end of their lifespan, reducing the demand for raw materials and minimizing waste. This sustainability aspect makes steel channels a preferred choice for eco-conscious construction projects. In conclusion, steel channels surpass other structural materials in terms of their strength, durability, design versatility, fire resistance, and environmental sustainability. With their numerous advantages, they prove to be a reliable and efficient choice for various construction applications.

- Q: Where can I find the tensile strength of channel steel?

- Tensile strength and yield strength are independent of size and size, but only material.Sigma S shall be the yield strength and the ultimate tensile strength shall be sigma BThe yield strength of Q215 material is 215MPa, and tensile strength is about 335-410MPaThe yield strength of Q235 material is 235MPa, and tensile strength is about 375-460MPa

- Q: Are steel channels suitable for seismic retrofitting?

- Yes, steel channels are suitable for seismic retrofitting. Steel channels are commonly used in seismic retrofitting projects due to their high strength and ductility. They can be used to reinforce and strengthen existing structures, especially in areas with high seismic activity. Steel channels are able to absorb and distribute seismic forces, making them effective in improving the structural integrity and performance of the building during an earthquake. Additionally, steel channels can be easily installed and integrated into existing structures, making them a popular choice for seismic retrofitting projects. Overall, steel channels are a reliable and suitable option for seismic retrofitting.

- Q: What are the different types of steel channel connections?

- Construction and structural engineering commonly employ various types of steel channel connections. Some frequently used ones include: 1. Welded connections: The most prevalent steel channel connection involves welding the ends of multiple channels together, ensuring a robust and enduring connection. Welded connections find application where the channel load is relatively low and adjustability is unnecessary. 2. Bolted connections: For higher channel loads and the need for adjustability or removability, bolted connections come into play. Bolts and nuts are used to connect the channels, making installation and modification easier compared to welded connections. 3. Riveted connections: While riveted connections were once popular, they have become less common due to the labor-intensive process involved. Rivets are used to connect channels, offering good strength and durability. However, specialized tools and skills are required for installation. 4. Gusset plate connections: Gusset plate connections employ a steel plate, known as a gusset plate, to connect multiple channels. The gusset plate is usually welded or bolted to the channels, enhancing strength and stability. This type of connection is commonly found in truss structures and applications with significant channel loads. 5. Cleat connections: Cleat connections involve using a steel plate, called a cleat, to connect a channel to another structural member, such as a beam or column. The cleat is typically bolted or welded to both the channel and the other member, ensuring a strong and stable connection. Cleat connections are commonly utilized in steel frame construction. These examples represent a fraction of the steel channel connections used in construction and structural engineering. The choice of connection type depends on factors such as load capacity, adjustability, installation requirements, and design considerations.

- Q: What are the specifications for steel channel coatings?

- The specifications for steel channel coatings typically include factors such as type of coating material, thickness requirements, adhesion properties, corrosion resistance, durability, and any specific industry standards or regulations that need to be met.

- Q: Large steel channel used for steel structural staircases

- If not sure, can see 15j401 Gangti atlas. Choosing proper channel steel can not only ensure the structural safety, but also achieve the goal of saving the cost! Hope to help you!

- Q: Can steel channels be used for both residential and commercial construction?

- Steel channels are suitable for both residential and commercial construction. These versatile structural components can be utilized in a variety of ways, such as in the construction of building frames, support beams, and walls and ceilings. Due to their strength and stability, they are well-suited for both residential and commercial projects. Furthermore, steel channels offer durability, fire resistance, and a high load-bearing capacity, making them an excellent choice for construction projects of various sizes and types.

- Q: What are the different quality control measures for steel channels?

- There are several quality control measures for steel channels that ensure their strength, durability, and overall quality. Some of these measures include conducting visual inspections to check for any defects or imperfections, performing dimensional checks to ensure accurate measurements, conducting mechanical tests to assess the strength and load-bearing capacity, and implementing surface treatment processes to prevent corrosion and enhance the appearance. Additionally, steel channels may undergo non-destructive testing methods such as ultrasonic or magnetic particle inspections to detect any internal flaws. Overall, these quality control measures help guarantee that steel channels meet the desired specifications and industry standards.

- Q: Are steel channels suitable for use in broadcasting towers?

- Yes, steel channels are suitable for use in broadcasting towers. Steel channels are commonly used in construction due to their strength and durability. Broadcasting towers require materials that can support the weight of the antennas and withstand various weather conditions, including strong winds and seismic activity. Steel channels are capable of providing the necessary structural integrity and stability required for broadcasting towers. Additionally, steel channels can be easily fabricated and assembled, which makes them a cost-effective choice for constructing tall structures like broadcasting towers.

- Q: What are the different load-bearing tests conducted on steel channels?

- There are several load-bearing tests that are conducted on steel channels to assess their structural integrity and performance. These tests help determine the maximum load that a steel channel can bear without failure. Some of the different load-bearing tests conducted on steel channels include: 1. Tensile Test: This test measures the maximum tensile strength of the steel channel by applying a gradually increasing axial load until failure occurs. It helps assess the channel's ability to resist pulling or stretching forces. 2. Compression Test: This test determines the maximum compressive strength of the steel channel by applying a gradually increasing axial load until it buckles or collapses. It provides insights into the channel's ability to withstand compressive forces. 3. Bending Test: In this test, the steel channel is subjected to a gradually increasing load applied perpendicular to its length until it reaches its maximum bending capacity. It assesses the channel's resistance to bending or flexural forces. 4. Shear Test: The shear test measures the maximum shear strength of the steel channel by applying a force parallel to its cross-sectional area until it fails. It helps evaluate the channel's ability to withstand shearing forces. 5. Fatigue Test: This test involves subjecting the steel channel to repeated and varying loads over a specified period to simulate real-world usage conditions. It assesses the channel's resistance to fatigue and its ability to withstand cyclic loading. 6. Impact Test: In this test, a sudden and high-velocity load is applied to the steel channel to simulate impact or shock loading. It helps evaluate the channel's ability to absorb and dissipate energy without failure. 7. Buckling Test: This test is conducted to determine the critical load at which the steel channel buckles or collapses due to instability. It helps assess the channel's resistance to buckling under compressive loads. These load-bearing tests are crucial in ensuring the reliability and safety of steel channels in various applications, such as construction, manufacturing, and infrastructure. By conducting these tests, engineers can determine the load limits and performance characteristics of steel channels, allowing for informed design decisions and ensuring structural integrity.

Send your message to us

Galvanized Steel C-Channel

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords