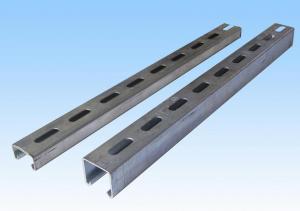

Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of MS Channel:

1.We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm

|

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Note: 1.we are also competent to provide our customers other MS Channel based on other sizes according to customer’s requirements.

2. The length of our ms channel could be cut into other meters as per customer’s requirements. For example, the channel in 6meters could be cut into 5.8meters in order to be fit in the 20ft container.

2. The detailed sections of MS Channel as per GB standard.are shown in the table-1:

GB U CHANNEL | Standard | Sectional | Dimension |

| Mass: |

| (mm) | (mm) | (mm) | (mm) |

|

50X37 | 50 | 37 | 4.50 | 7.0 | 5.438 |

63X40 | 63 | 40 | 4.80 | 7.5 | 6.634 |

80x43 | 80 | 43 | 5.00 | 8.0 | 8.045 |

|

|

|

|

|

|

100x48 | 100 | 48 | 5.30 | 8.5 | 10.007 |

120x53 | 120 | 53 | 5.50 | 9.0 | 12.059 |

140x58 | 140 | 58 | 6.00 | 9.5 | 14.535 |

140x60 | 140 | 60 | 8.00 | 9.5 | 16.733 |

|

|

|

|

|

|

160x63 | 160 | 63 | 6.50 | 10.0 | 17.240 |

160x65 | 160 | 65 | 8.50 | 10.0 | 19.752 |

|

|

|

|

|

|

180x68 | 180 | 68 | 7.00 | 10.5 | 20.174 |

180x70 | 180 | 70 | 9.00 | 10.5 | 23.000 |

|

|

|

|

|

|

200x73 | 200 | 73 | 7.00 | 11.0 | 22.637 |

200x75 | 200 | 75 | 9.00 | 11.0 | 25.777 |

|

|

|

|

|

|

220x77 | 220 | 77 | 7.00 | 11.5 | 24.999 |

220x79 | 220 | 79 | 9.00 | 11.5 | 28.453 |

|

|

|

|

|

|

250x78 | 250 | 78 | 7.00 | 12.0 | 27.410 |

250x80 | 250 | 80 | 9.00 | 12.0 | 31.335 |

250x82 | 250 | 82 | 11.00 | 12.0 | 35.260 |

|

|

|

|

| |

280x82 | 280 | 82 | 7.50 | 12.5 | 31.427 |

280x84 | 280 | 84 | 9.50 | 12.5 | 35.823 |

280x86 | 280 | 86 | 11.50 | 12.5 | 40.219 |

|

|

|

|

|

|

300x85 | 300 | 85 | 7.50 | 13.5 | 34.463 |

300x87 | 300 | 87 | 9.50 | 13.5 | 39.173 |

300x89 | 300 | 89 | 11.50 | 13.5 | 43.883 |

Table-1

3. The chemical composition of HR Channel Steel according to Q235B is shown in Table-2.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12-0.20 | 0.3-0.7 | ≦0.045 | ≦0.045 | ≦0.3 |

Table-2

Note: we are able to present our customers relevant SGS test report for chemical composition of HR Channel Steel.

4. The mechanical property of HR Channel Steel according to Q235B is shown in Table-3-1 and Table-3-2

Alloy No | Grade | Yielding Strength Point(Mpa) | |||

Thickness(mm) | |||||

≦16 | >16-40 | >40-60 | >60-100 | ||

≧ | |||||

Q235 | B | 235 | 225 | 215 | 205 |

Table-3-1

Alloy No | Grade | Tensile Strength(Mpa) | Elongation After Fracture(%) | |||

Thickness(mm) | ||||||

≦16 | >16-40 | >40-60 | >60-100 | |||

≧ | ||||||

G235 | B | 375-500 | 26 | 25 | 24 | 23 |

Table-3-2

Note: we are able to present our customers relevant SGS test report for mechanical property of MS Channel as customer’s request.

Applications of MS Channel:

The MS Channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc.The hot rolled channel steel belongs to carbon structural steel which is applied to in the field of construction and machinery.In details, the hot rolled channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the hot rolled channel steel we supply must possess perfect welding property, riveting property and mechanical property and so on.

Package & Delivery of MS Channel:

1.The hot rolled channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

2. And the hot rolled channel steel could be loaded into 20ft or 40ft container, or by bulk cargo.If the weight of each bundle reaches more than 3.5 mt, the loading by break bulk cargo should be choosed.When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

3.As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4.All in all, we could do in accordance with customer's request.

- Q: What are the factors that affect the price of steel channels?

- The factors that affect the price of steel channels include the cost of raw materials, such as iron ore and coal, as well as production and transportation costs. Demand and supply dynamics, including global economic conditions and construction activity, also play a significant role in determining the price of steel channels. Additionally, external factors like government policies, trade regulations, and currency fluctuations can impact the cost of steel channels.

- Q: What is the allowable bending strength of Q235 channel steel? Why does the mechanical manual have no bending strength?

- Q235 channel design value of general 215N/mm^2, such as thin-walled steel pipe design values, such as 205N/mm^2.

- Q: Which kind of wind resistance is better for square tube, square tube or channel steel?

- Square pipe and channel steel that load-bearing better 1, the same thickness and area, square superior to channel. 2, if the channel is closed to a rectangular tube, then the channel is better than the square tube.

- Q: What are the typical finishes available for steel channels?

- Steel channels can be finished in various ways to achieve different aesthetic and functional requirements. One option is to use hot-dip galvanizing, where the steel channel is immersed in molten zinc. This method not only provides excellent corrosion resistance but also adds a decorative touch with a shiny and even surface. Another choice is powder coating, which involves applying a dry powder onto the steel channel and then curing it with heat. This finish is highly durable and attractive, resistant to chipping, scratching, and fading. It can be customized in different colors to suit individual preferences and blend with the surroundings. Electroplating is also popular for steel channels. It entails immersing the channel in an electrolyte solution and passing an electric current through it, resulting in a layer of metal (such as chrome or nickel) being deposited on the surface. This process enhances the appearance of the channel with a smooth and shiny finish while providing some corrosion resistance. For a more natural and rustic look, steel channels can be left unfinished or with a bare metal finish. This option is often chosen for industrial or architectural designs where the raw and exposed metal is desired for its aesthetic appeal. In conclusion, the available finishes for steel channels include hot-dip galvanizing, powder coating, electroplating, and bare metal finishes. Each finish offers its own unique benefits in terms of corrosion resistance, durability, appearance, and customization options, providing a wide range of applications and design possibilities.

- Q: What are the weight calculations for steel channels?

- The weight calculations for steel channels depend on the dimensions and type of channel being used. To calculate the weight of a steel channel, you would typically multiply the cross-sectional area of the channel by the density of steel. The cross-sectional area can be calculated using the height, width, and thickness of the channel. It is important to consult engineering references or use specialized software to accurately determine the weight of steel channels based on their specific dimensions and specifications.

- Q: What does channel specification "MQ-41" mean?

- Channel MQ-41 is the product model named by the manufacturing company, in which MQ is the product form, and the 41 is the side height.

- Q: What are the different load distribution techniques for steel channels?

- Steel channels can be subjected to different load distribution techniques. 1. One technique is the uniform load distribution, which evenly distributes the load across the entire length of the steel channel. This method is suitable for cases where the load is evenly distributed or when there isn't a specific point of concentrated load. 2. Another technique is concentrated load distribution, where the load is concentrated at specific points along the steel channel. This is commonly used in areas where the load is expected to be higher, such as support points or connection joints. 3. Variable load distribution is a technique that involves varying the load distribution along the length of the steel channel. It is used when the load is not evenly distributed and varies from one point to another. This can be achieved by adjusting the spacing between the supports or implementing additional support mechanisms like beams or braces. 4. Sometimes, a combination of load distribution techniques is employed to optimize the structural integrity of the steel channel. This may involve using uniform load distribution for the majority of the length, while concentrated load distribution is utilized at specific points where the load is expected to be higher. Various factors, including the nature of the load, structural requirements, and the intended use of the steel channel, should be taken into account when choosing a load distribution technique. Consultation with a structural engineer is crucial to determine the most suitable load distribution technique for a specific application.

- Q: Can steel channels be customized for specific applications?

- Yes, steel channels can be customized for specific applications. The dimensions, lengths, shapes, and finishes of steel channels can be tailored to meet the specific requirements and needs of different applications, ensuring optimal performance and functionality.

- Q: 14# dimension of channel steel and weight per metre?

- Specification for dimensions and weight of hot rolled ordinary channel steel14#a height (H) 140, leg width (b) 58, waist thickness (d) 6, theoretical weight 14.535 kg14#b height (H) 140, leg width (b) 60, waist thickness (d) 8, theoretical weight 16.733 kg

- Q: What are the different methods for transporting and handling steel channels?

- There are several different methods for transporting and handling steel channels, depending on the specific requirements and logistics of the situation. Some of the commonly used methods include: 1. Crane lifting: Steel channels can be transported and lifted using cranes equipped with hooks or lifting magnets. This method is ideal for large-scale projects or when handling heavy steel channels. 2. Forklifts: Forklifts with specialized attachments can be used to transport steel channels within a facility or construction site. This method is suitable for smaller and lighter steel channels, allowing for more precise movement and placement. 3. Conveyor systems: In manufacturing settings, conveyor systems can be implemented to transport steel channels from one process to another. This method is efficient and reduces the need for manual handling. 4. Flatbed trucks: Steel channels can be loaded onto flatbed trucks for transportation over long distances. The channels are secured using straps or chains to prevent movement during transit. 5. Palletizing: Steel channels can be stacked and secured on pallets for easier handling and transportation. This method is common when shipping smaller quantities of steel channels or for storing them in a warehouse. 6. Rollers or skids: Steel channels can be moved along rollers or skids for short distances within a facility or construction site. This method allows for easy movement and positioning of the channels. 7. Rail transportation: For larger quantities or longer distances, steel channels can be transported via rail. Specialized rail cars or containers are used to safely secure and transport the channels. It is important to consider the size, weight, and fragility of the steel channels when determining the appropriate method for transporting and handling them. Safety measures should always be followed to prevent accidents, and specific equipment may be needed depending on the chosen method.

Send your message to us

Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords