Polymer cable tray Trough type cable tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name:

Polymer Trough type cable tray

Introduction:

Polymer cable tray is a tray product of new materials. It is suitable for petroleum, chemical industry, textile, electric power, machinery, transportation, civil construction and other fields. It can replace the traditional metal bridge at present and is the cable bridge for future engineering applications.

Material feature:

1.Polymer cable tray is made of high new polymer material PVC and ABS polystyrene oxygen and other materials. It has the advantages of strong heat resistance, low thermal expansion coefficient, good flame retardant, high insulation performance, strong corrosion resistance, long service life and so on. Compared with traditional products, it has great advantages.

2. The optimized design of the structure improves the flexibility and speediness of the installation of the cable tray. The traditional cable tray structure is complex and requires many parts, while the new alloy plastic cable tray can greatly meet the needs of customers by using only dozens of parts, which greatly improves the flexibility and speed of cable tray installation.

3. Improve the utilization rate of polymer materials, through verification than the conventional increase of about 5%. Polystyrene oxygen has outstanding mechanical properties, especially tensile strength, impact strength, corrosion resistance and creep resistance. Under 21Mpa load for 3000h, the creep value is 0.75%, while PC is 1%, POM is 2.3% and ABS is 3%. Through the full mixing with PVC, improve the utilization rate, more than 5% higher than conventional.

4. The product has good appearance design and high decoration. And the product is made of plastic material, by injection molding and extrusion molding, has a good appearance design, through structural optimization design, so that it can be arbitrary combination, decorative strong, overcome the traditional products poor appearance, low decorative performance shortcomings.

5. High polymer cable tray has long service life. Compared with the traditional steel cable tray, the service life is 5-8 times longer, which reduces the secondary input cost of replacing the cable tray. The corrosion resistance of traditional steel cable tray products is poor, and the cable tray must be coated and repaired regularly. The cost of materials and labor is high, and the corrosion resistance of polymer tray is strong, which greatly reduces the maintenance cost and maintenance time. Alloy plastic cable tray does not need power outage during maintenance, and the loss caused by production suspension is correspondingly reduced, which effectively improves the production efficiency.

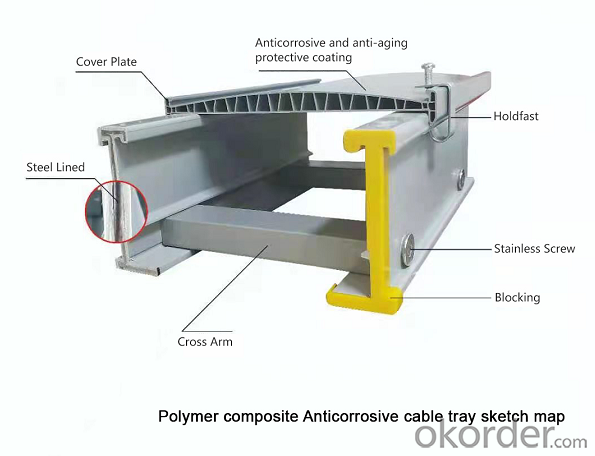

Parts:

Cover Plate、Steel Lined、 Cross Arm、Blocking 、Stainless screw、Holdfast、Anticorrosive and anti-aging protective coating

Process:

Built in steel plate extrusion molding .All parts can be galvanized

Application:

It is suitable for petrochemical factory、chemical plants with high salinity、Bridges, tunnels, hotels, etc. It is suitable for power cables below 10K.

- Q: What is the angle of the cable bridge climbing angle?

- If it is the same style, then the cable protection tube its inner wall may be 2.8mm it, like .20 and the like may be inside the bar.

- Q: What is the installation specification for the cable tray bracket?

- You may be filled with material. If the material in the core gap, that is, filling material, only to ensure roundness, can not afford any effect

- Q: Metal trunking national standards, wire and cable bridge national standards

- It is estimated that you do not use CAD software to do, it should be based on CAD secondary development of some software to do the drawings, use the software to open the job, or a lot of things will not show

- Q: How the spacing of the hangers of the bridge is determined

- Cable ends should be marked with cable head symbols, the middle line should also be different from the ordinary wiring. Bv at the beginning of the general wire, with YJV or vv is generally a cable, but not limited to these

- Q: What is the meaning of the separation within the cable tray?

- Negative pole connected to the body and the engine ground, the pole is connected to the motor starting horse, and all electrical equipment, hoping to help you! The The [Car problem, ask the car master. 4S shop professional technician, 10 minutes to solve. To

- Q: What are the specifications for cable tray installation? What should I pay attention to when installing?

- Copper core XLPE insulated PVC sheathed flame retardant power cable, 5x6mm2

- Q: Our drawings are messy, some cableway or walk the bridge it also wear steel pipe, I would like to have this need to explain, we this project is the highest 23 layers more

- It is to be installed and Ming Tu, not concealed and dark laying.

- Q: Especially the trough bridge and tray tray, what is the biggest difference between the two? Is there a difference in appearance? More

- . if the TV screen appears set-top box to start the image and then prompt "no signal" case, this phenomenon proves that your set-top box and the TV between the audio and video lines (red, yellow, white) connection is basically no problem, but TV radio frequency input signal line (Note: not the red and yellow that three) did not receive the set-top box RF input port, or TV RF input signal line and the wall is not connected to the terminal box, or in your room there are other places where the road. . if the TV screen does not appear set-top box to start the image, then just the blue screen and no text prompts, then that is your TV channel settings there is a problem, please use the TV remote control by source or AV / TV key, the TV from the mold helium chicken meal berry wine every time to change the video channel can be converted to video channels. If the above method still can not be resolved, you must call the local cable TV customer service phone, ask the professional maintenance staff to help. Prompt, no need and do not have to re-search.

- Q: Does the weak and fire can share a cable tray?

- Specific can not be sure, it is recommended that you in the billing system through the tax classification code input power gold fuzzy search, according to find out the content, select a description of the most can be.

- Q: I would like to ask you, you generally do steel plant, how to lay the bridge feel better? I have some drawings, 1. Some of the bridge laying in the I-beam column, 2. Some of the bridge laying on the wall, 3. There are bridges along the steel roof truss lay, I went to know the appearance of steel roof truss, There are winding, chord, the middle of the abdomen is used to insist on the upper and lower sides, but that is along the winding, roof truss sometimes not linear level, sometimes for example triangular steel truss, not the level of the winding how to walk it? Is it easy to walk? Do not know where you design steel plant, the bridge how to design the best, the most appropriate? Thank you! More

- Can use 2.5 square copper wire. Power line cross section is not safe, big too wasteful.

Send your message to us

Polymer cable tray Trough type cable tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords