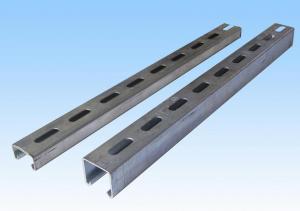

Galvanized and Stainless Steel Channel Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized and Stainless Steel Channel Steel

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Dimensions: | Standard and nonstandard. | Grade: | As your order. |

Place of Origin: | China (Mainland) | Brand Name: | BOCHI | Perforated Or Not: | Not Perforated |

Shape: | Both U and C type. | Application: | Construction | Paint: | We can paint as order. |

Packaging & Delivery

Packaging Detail: | By bundle and tied with steel strips. |

Delivery Detail: | 15-35 days after receiving deposit. |

Galvanized and Stainless Steel Channel Steel Specifications

1.Standard and nonstandard are provide.

2.Material can as order.

3.Quality ensure.

4.Best after-sell service.

Galvanized and Stainless Steel Channel Steel Features

1.Material from famous steelworks,such as Baosteel,Wuhan steel,etc.

2.We have advanced technology.

3.Special specifications are available.

4.Welcome you inspection before delivery.

5.ISO9001,TS16949,AS9100,DNV,CCS and other classification society certificate is available.

6.Reasonable price and best after-sell service.

Galvanized and Stainless Steel Channel Steel Pictures

- Q: Which kind of wind resistance is better for square tube, square tube or channel steel?

- Why don't you buy square tubes directly? How do you budget?

- Q: What are the advantages of using hot-rolled steel channels?

- Some advantages of using hot-rolled steel channels include their high strength-to-weight ratio, durability, and cost-effectiveness. Hot-rolled steel channels are able to support heavy loads while minimizing material weight, making them ideal for structural applications. Additionally, their hot-rolled manufacturing process ensures a consistent and uniform shape, resulting in accurate and easy installation. Furthermore, hot-rolled steel channels are often more affordable compared to other materials, making them a popular choice for various construction projects.

- Q: Are steel channels suitable for seismic zones?

- Yes, steel channels are suitable for seismic zones. Steel is a strong and ductile material that can effectively resist seismic forces. Steel channels are commonly used in seismic design and construction due to their ability to provide structural stability and resilience during earthquakes. They offer excellent strength-to-weight ratio, flexibility, and resistance to bending and shearing forces, making them a reliable choice for seismic zone applications.

- Q: Can steel channels be used for supporting walkways and platforms?

- Indeed, walkways and platforms can be supported by steel channels. In construction endeavors, steel channels are widely employed due to their robustness and endurance. These channels furnish a firm and steadfast support framework, rendering them optimal for walkway and platform support. They can be tailored to meet precise load demands and effortlessly assembled to forge a secure and trustworthy structure. Furthermore, steel channels can undergo galvanization or coating to enhance their resistance against corrosion, thereby guaranteeing their longevity and safety.

- Q: Are steel channels suitable for cold storage facilities?

- Yes, steel channels can be suitable for cold storage facilities. Steel channels are known for their strength and durability, making them ideal for supporting heavy loads and withstanding extreme temperatures. Cold storage facilities require materials that can withstand low temperatures without compromising their structural integrity, and steel channels are able to meet these requirements. Additionally, steel channels are resistant to corrosion, which is crucial in cold storage facilities where moisture and condensation can be present. Overall, steel channels offer the necessary strength, durability, and resistance to corrosion that make them a suitable choice for cold storage facilities.

- Q: Can steel channels be used for roofing applications?

- No, steel channels are not typically used for roofing applications. Roofing materials such as shingles, tiles, or metal sheets are more commonly used for this purpose.

- Q: Are steel channels suitable for agricultural buildings?

- Yes, steel channels are suitable for agricultural buildings. Steel channels offer several advantages that make them ideal for agricultural structures. Firstly, steel channels are known for their high strength and durability. They can withstand heavy loads and harsh weather conditions, making them suitable for supporting the weight of agricultural equipment, storing feed, and withstanding the elements. Additionally, steel channels are resistant to pests, such as termites and rodents, which are common in agricultural environments. This makes them a more reliable and long-lasting option compared to other materials that may be susceptible to pest damage. Moreover, steel channels are fire-resistant, reducing the risk of damage or loss in the event of a fire outbreak, which is crucial for the safety of livestock and stored crops. Furthermore, steel channels are highly versatile and can be easily customized to suit the specific needs of agricultural buildings. They can be designed to accommodate various layouts and configurations, allowing for efficient use of space and optimal functionality. Lastly, steel channels require minimal maintenance over their lifespan, reducing the overall cost of ownership for agricultural buildings. This is particularly beneficial in the agricultural sector, where time and resources are often limited. Considering these factors, it is clear that steel channels are a suitable and advantageous choice for agricultural buildings, providing strength, durability, versatility, and cost-effectiveness.

- Q: Can steel channels be used for overhead door framing?

- Yes, steel channels can be used for overhead door framing. Steel channels are often used in construction for their strength and durability, making them suitable for supporting the weight and movement of overhead doors.

- Q: Are steel channels suitable for use in the construction of conveyor systems?

- Yes, steel channels are suitable for use in the construction of conveyor systems. Steel channels offer a number of beneficial properties that make them ideal for this purpose. Firstly, steel channels provide excellent strength and durability, allowing them to withstand the heavy loads and constant movement typically associated with conveyor systems. They also have high resistance to corrosion and wear, ensuring a longer lifespan and reducing the need for frequent maintenance or replacement. Additionally, steel channels can be easily customized and fabricated to meet specific design requirements, allowing for a more efficient and effective conveyor system. Overall, the use of steel channels in conveyor system construction can enhance the system's functionality, reliability, and longevity.

- Q: What are the common lengths of steel channels?

- The common lengths of steel channels can vary depending on the specific application and manufacturer. However, some standard lengths are commonly available in the market. These include 10 feet (3.048 meters), 20 feet (6.096 meters), and 24 feet (7.315 meters). These lengths are often preferred due to their convenience in transportation and handling. It is important to note that custom lengths can also be ordered from manufacturers to suit specific project requirements.

Send your message to us

Galvanized and Stainless Steel Channel Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords