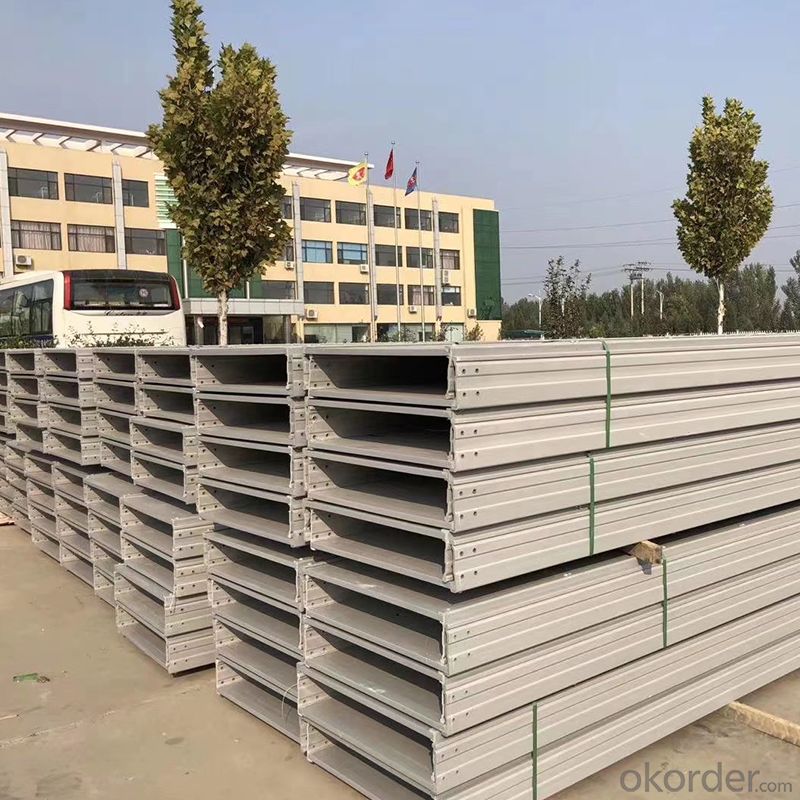

Polymer composite cable tray with steel-plastic

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 m

- Supply Capability:

- 200000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The cable tray produced by the company has a wide range of varieties and specifications, and has more than 30 various production lines, which has become a large-scale production base.

The company has established a complete quality assurance management system and obtained ISO9001: 2015 quality management system certification and IS045001: 2018 occupational health and safety management system certification. Over the years, the company's credit rating has reached "AAA", and it has been rated as "Contract-honoring and Promise-keeping Unit" and "Credibility Demonstration Unit in the Metal Plastic Products Industry".

The company is developing in the direction of scale and industrialization with a solid and steady pace. The company attaches great importance to innovation, and always adheres to the principles of industrial innovation, honest cooperation, and customer first, and provides exquisite products and services that customers need.

Packing details:

Suitable for sea transportation, and the strapping is wrapped with a strong steel belt.

Delivery details:

15-30 days after receiving 50% advance payment.

Production capacity:

500,000 meters per year.

Product implementation standard:

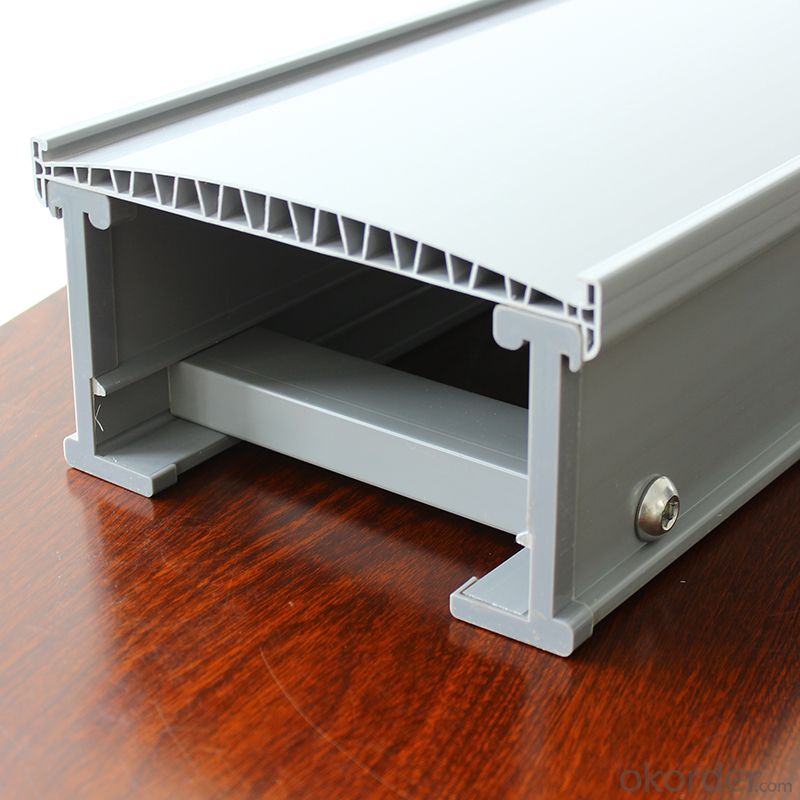

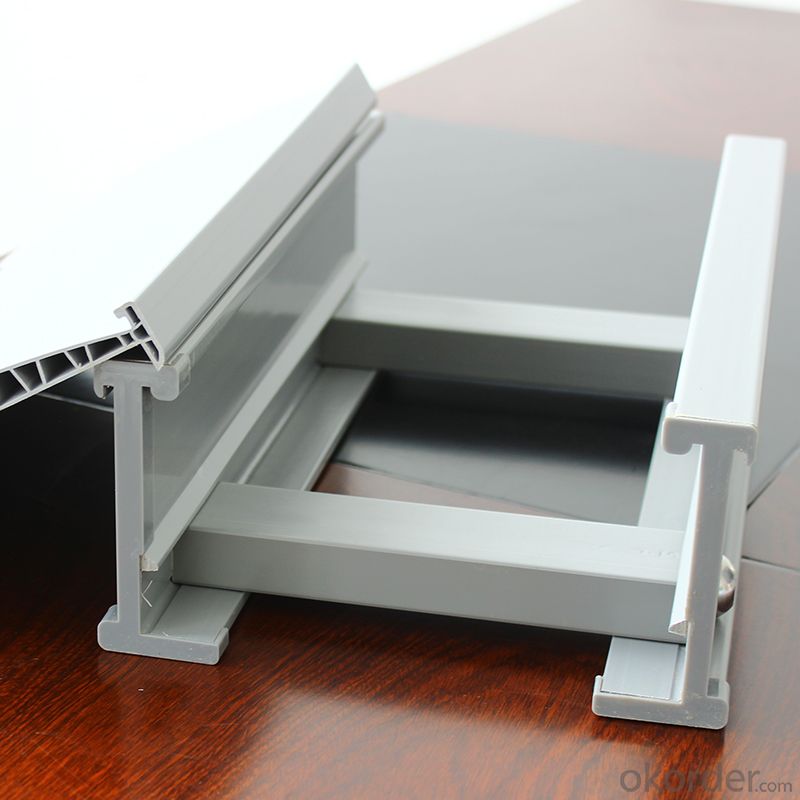

Industry standard JB/T 10216-2013 <

Side thickness:

6-8mm

Product length:

6m/section.

Thickness of lining galvanized sheet:

2.0mm

Place of Origin of Lining Steel Plate:

Hebei Iron and Steel SXXXGD series.

Origin of polymer layer:

Tianjin Daguhua Type 5 PVC.

Standard for connecting screws and hooks:

304 stainless steel.

Certification certificate:

Quality management system, occupational health and safety management.

Bottom support specification:

40mm*20mm.

Slot bottom plate specification:

20mm.

Cover width:

According to customer requirements.

Color:

According to customer needs.

- Q: Always confused the bridge has been linked with copper mesh with a why even laying a galvanized flat iron. More

- There may be bad business is now very dark, but if it is customer service should be no problem if it is hard to say

- Q: What is the national standard of the thickness of the bridge?

- Control cable is not high voltage, the maximum voltage level 0.6 / 1kV, are generally 450 / 750V

- Q: What is the meaning of the bridge and the non-perforated tray on the electrical drawings?

- Your chassis is also supporting the back line, then the backplane threading hole reserved must also be reasonable and adequate

- Q: In the bridge of the joints with a number of bolt cover fixed, there is a 20 cm long copper wire prepared by the flat, both ends were lap on the bolt. I do not know the role of this with the flat belt? Who knows, please enlighten me, thank you! More

- This can only say "possible"; if you encounter unscrupulous maintenance workers, may be so dry; However, air-conditioning brass as long as the use of its flexibility will become very poor, a little careless will be flat of. Brass tube, the safest way is to replace the brass.

- Q: 5 4 * 95 + 1 * 75 cable should choose what size of the bridge

- My house is just a balcony, bathroom ceiling, is the PVC buckle board, I did not wear pipe if it is gypsum ceiling, should wear, gypsum corrosive

- Q: Can the cable bridge be on the ground?

- The bridge is a bracket that supports and releases cables. Bridge is very common in the use of the project, as long as the laying of the cable will use the bridge, cable bridge as a wiring project supporting a project, there is no special specification guide, a manufacturer's specifications program lack of versatility, therefore, design selection The process should be based on the weak system of each system cable type, quantity, reasonable selection of the applicable bridge. Cable bridge with a wide variety, wide application, strength, light structure, low cost, simple construction, flexible wiring, installation standards, beautiful appearance and so on. But the laying of the ground is contrary to the design of the use of the scope of the bridge.

- Q: How to lay the multi - layer cable in the trough

- Directly to the computer that VGA data cable into the TV's VGA interface, and then use the remote control to change the mode of VGA can be used

- Q: Water pipe must go in the bridge below it, which norms have provisions, seeking detailed solution. It is best to tell me the first few chapters.

- People are relatives, the relationship between you and the relationship between the students to go deeper, the same price, quality will not choose your case. Quality, price, brand, person, network, sales strategy, etc., out with the relative comparison of your relatives how much advantage? In these conditions for the person is the most important, say before doing things first person. It is not to find a goal!

- Q: (E-5A-4) is an ideal protective material for the energy industry (nuclear power, petrochemical industry) emergency circuit, cable tray fire separation, and other electrical control systems. More

- There are so many cables connected to the top of the elevator box, to the elevator power supply, including control cables, power cables, lighting cables, see below:

- Q: What are the specific fireproof materials that are sprayed on the surface of the fireproof bridge, and hope that the professionals will answer.

- This approach can be used for floor-to-house network data transmission to the client.

Send your message to us

Polymer composite cable tray with steel-plastic

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 m

- Supply Capability:

- 200000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords