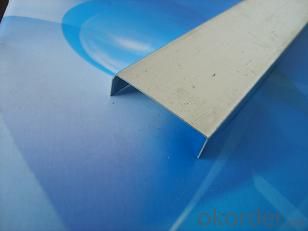

Galvanized Metal Steel C-Channel Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building, bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1)Rust proof

2)Corrosio-resistance

3)Multi-roll production technology

4)Fireproof, anti-seismic

5)Environmental friendly, Pls Be Assured Use

6)Easy installation, precisely dimensioned

Main Product Features:

1.Type: Ceiling grid or drywall partition component

2.Thickness:0.4-1.2mm, size:42*25, 52*25, 72*25, 75*25, 100*34.5

3.Length: 2800mm, 3000mm, 3200mm

4.Light weight, high strength

5.Package:10pcs per bundle with plastic strip or iron wire

6.MOQ: 10 Tons, negotiable

7.Delivery time: 15-20 days.

8.Payment term: via T/T, 30% payment, balance before shipment.

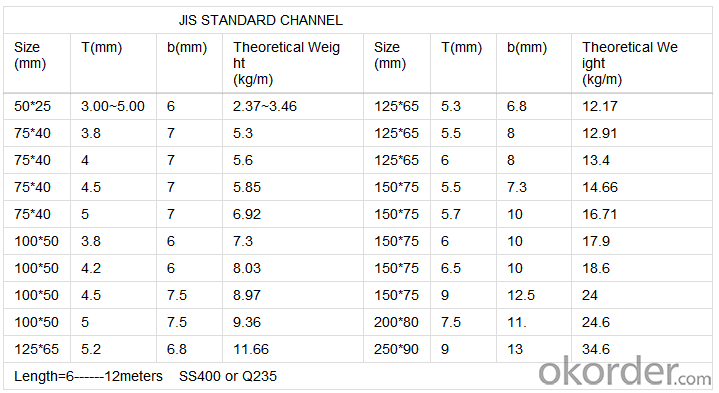

Product Specifications:

Images:

- Q: The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- 1: you have the conditions or bricklayers, practice: build the wall of the place, you can add a reverse beam (plus a beam on the floor) and then wall, reinforced concrete beam; another direct to do the word steel or channel to do Beam, pay attention to the two heads to be on the point of support. Build the wall again. ? 2: do light steel keel gypsum board wall accidentally wear a hole. Is a short time to be. Not moisture, is easy. 3: the floor can be made of wood, the material with a little bigger. Encrypt a little bit. The problem is not big, other solid floor to do on the ground fixed point has changed the day.

- Q: Light steel keel cut off the keel and the ground with what fixed?

- Playing a good line, with 25 steel nails directly to the keel to the ground fixed, If the ground is too hard nails do not enter, use hammer to play the cork now, and then in the fixed keel.

- Q: Light steel keel wall waterproof

- The grass on the surface of the gray skin with a knife to remove, with a broom to dust, sand and other debris clean, especially the root, floor drain and drain and other parts to be carefully cleaned. If there is oil, apply wire brush and sandpaper brush off. The base surface must be flat, the depression should be filled with cement putty.

- Q: Gypsum board partition wall how to sound insulation

- Single-walled wall due to the law of quality constraints, must be a heavy wall in order to obtain good sound insulation performance. For the office partition wall, in order to meet the national minimum standard rw = 40db requirements of single-layer partition at least 100kgm2 above the surface density (surface density is the weight per square meter of the wall). If the wall is divided into two or more layers, the sound insulation will be significantly improved.

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Mainly to see the use of the environment, if used in a humid environment, the life must be short, so the bathroom wall is best not to use light steel keel search.

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- You said the mineral wool board and gypsum board can not be used because they are not waterproof tide will be deformed Recommended ceiling with PPC or aluminum gusset plate is to do with the wall with calcium silicate board is the cement board on the line waterproof paint with a little better is no problem

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- Light steel keel is attached to the gypsum board, it can be seen, the installation of light steel keel spacing is based on the thickness of the gypsum board to decide. Like the 12mm gypsum board, its spacing is 450mm, according to the gypsum board to determine its spacing. Finally, in the adjustment of hanging pieces into the keel inside the appropriate rotation can be consistent.

- Q: Light steel keel partition wall construction process is what

- Processes: Bracket, Divider Pillow Pillow (Design Required) Fixed along the top, along the keel fixed Bone keel installation Vertical keel installation door, window frame installation Additional keel installation Support keel, check keel installation Electrical pipe , Installation of the installation of the wall equipment, a cover panel filled with sound insulation material installation, the other side of the panel panels and corners of the treatment of quality inspection.

- Q: Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q: Gypsum board wall is generally done to the height of the original roof or do the height of the ceiling?

- With the requirements of the party, both methods are to do, to sound or privacy is good point, then we must be separated from the top, to save money and then save money on the next day it can be on the next day.

Send your message to us

Galvanized Metal Steel C-Channel Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords