Galvanized Hanging Wire Roll for Installation of Suspended Drop Ceilings

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Hanging Wire Roll for Installation of Suspended Drop Ceilings

1. Structure of Galvanized Hanging Wire Roll for Installation of Suspended Drop Ceilings Description:

Galvanized Iron Wire is made with choice mild steel, through wire drawing, wire galvanizing and other processes. Galvanized iron wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.

Galvanized Iron Wire can be supplied in the form of coil wire, spool wire or further processed into straightened cut wire or U type wire. It is mainly used in construction, express way fencing, binding of flowers and wire mesh weaving.

2. Main Features of Galvanized Hanging Wire Roll for Installation of Suspended Drop Ceilings:

• Antirust

• Shiny silvery color

• High strength

• Durable

• Versatile

• Good visual effect

3. Galvanized Hanging Wire Roll for Installation of Suspended Drop Ceilings Images

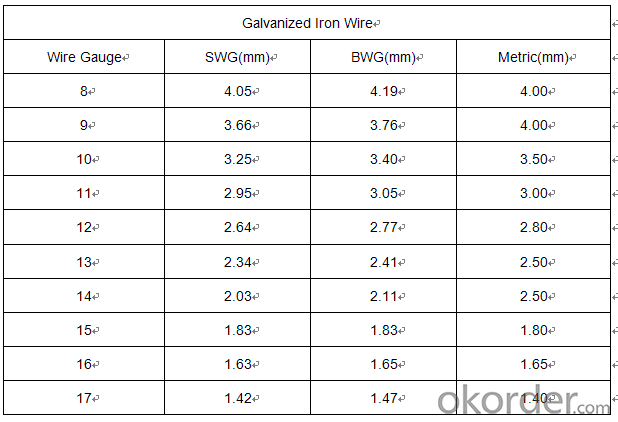

4. Galvanized Hanging Wire Roll for Installation of Suspended Drop Ceilings Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your products?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional Galvanized Hanging Wire Roll for Installation of Suspended Drop Ceilings factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world.Different kinds of wires and mesh are available according to customer’s requirements.

② How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;Our company has good marketing network and abundant operation experience. Galvanized Iron Wire are sold to all parts of the country, at the same time, exported to Southeast Asia,The management theory is based on sincerity, keeping forging ahead. We have accumulated a whole set of marketing experience, having already become a local leader engaged in steel products.

③ How long can we receive the product after purchase?

In the purchase of Galvanized Hanging Wire Roll for Installation of Suspended Drop Ceilings within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: I have a 2002 Chevy blazer 4.3 motor we'll I found some wires that look like trailer wires on the back of the car and I'm trying to connect a 4flat trailer plug in. So the wires are following on the car. Yellow is left blinkerGreen is right blinkerBrown is running lights Blue is brake lightsWhite groundSo the 4 flat wires are as following White groundYellow is left turnGreen is right turnBrown is taillightsSo my question is how can I get my brake lights and running lights on the trailer plug in. Cause I have 5 wires on my vehicle and only 4 on my trailer plug. Please help

- On okorder /... also available at your local auto parts store

- Q: I have a water valve that I need to connect but I don't know how to read this diagram. I'm unsure how to connect the wires to the cold and hot valve. I have four wires that need to be connected. A pair of white caps with one blue wire and one orange; and a pair of black caps with one blue wire and one yellow wire. Sorry if this sounds confusing but I have no idea how to explain it well. Thanks!

- blue and yellow for cold valve one, blue and orange for cold valve 2, the hot valve would be blue and brown.

- Q: I have 12/3 wire running from the breaker box on a 20 amp breaker that powers a bathroom (2 lights and 2 receptacles). I want to splice into this and run 14/2 wire into the living room to run 6 recessed lights. Is this OK to do?

- No you should either use a 20 amp breaker and 20 amp recepticles or if you use a 15 amp breaker then use 14/2 or 14/3 wire. Too heavy of wire creates a fire risk. If your new home was wired to code, this seems quite odd.

- Q: I m wondering if there s a Neutral Wire in this picture (yes I turned off the breaker to get this photo). I want to put in a quot;Smart Light Switchand they require a Neutral Wire. I ll have an electrician do the work, but want to make sure the wire exists first.

- The neutral is the white wire on the receptacle.

- Q: What type of wire do i need to install a normal inside wall outlet? Do i have to use solid copper wire?

- If the circuit breaker feeding the receptacle is 15 amps, you must use a #14 minimum size. if it is a 20 amp breaker, you must use a #12 minimum. You can use either solid or twisted. TexMav

- Q: On the wires leading to existing system I can see the main power lead. However all the other wires are different in color leading to existing valves. From the wire bundle two black wires (the only black wires) lead out to nothing and were left with no electrical end caps protecting. Manual says nothing on wiring valves. Any ideas on black wires? Or how can I splice in to existing system wires at valve point having one valve working at a time when system is operating? Am I going to have to get a new controler or run new wires existing controler?

- The wire that goes to all the valves is the common. The other color wires go to the other wire on the valves. One colored wire per valve. That is how the valve gets power. It is common to run extra wires when doing a sprinkler system. So the 2 wires that are not being used are there just in case you ever need them. So tie one wire from each valve to the common then the other wire to an unused wire. Just make sure that your timer is capable of handling the extra valves.

- Q: Can anyone give me some info or a website with info on which type of wire carries sound waves best?

- Wire does not carry soundwaves, at least not unless the ends of the wire have tin cans on them, and the wire is pulled taut between them! Wires can carry electrical signals which can be used to reproduce the sounds that caused them. This is how sound comes from such as your stereo system's speakers. Maybe that's what you actually mean? If so, copper wires (insulated, of course) are what you want, and if the distance you run the wires is great, the heavier the wire (gauge) the better. If you are transmitting high power to speakers, the wires have to be capable of handling the electrical current involved.

- Q: Hello, I have a 4 year old Trane XR12 unit. Recently the compressor fan is noisy, and now stops when when under power after 5-10 min. The main fuses and breakers are fine, the fan spins freely when turned, the contactor pulls in fine, the dual capacitor checks out. But, the wiring of the capacitor does not match wire diagrams. Could this have caused the fan motor to prematurely fail?..............................Terminal: C red wire, FAN brown wire, HERM has both orange and purple. Schematic shows the purple wire should be with red wire on common C. The purple also leads to fan.

- Hi, I looked at the schematic on-line. If you still have the original fan motor in the unit then you are correct. The center terminal on the capacitor should have the red wire from the T1 terminal of the contactor, the red wire from the compressor, and the purple wire from the fan. The FAN terminal should have the brown wire from the fan. The HERM terminal should have the orange wire from the compressor. The black wire from the fan and the black/blue wire from the compressor should lead back to the T2 terminal of the contactor. Again, that is if the motor is the original motor. If it was replaced at some point in time, the wiring colors can change from manufacturer to manufacturer, in which case it's possible that the new motor is wired correctly. There should be a diagram on the motor to show you the correct wiring configuration.

- Q: How do I wire with reg 5 wire T-Stat Installing a 2 ton Goodman A/C cond unit to a old Carrier Heat pump AHU with emergency heat strip.

- red is your low voltage green is your fan yellow is your cool brown is your com orange is your heat how many wires do you have on the old one should be color to color

- Q: Can we use pilot wire protection to protect overhead line, and which country use this scheme ?

- Pilot wire protection can be used anytime anywhere. The question is not where it is used but why, and is it required. Pilot wire protection provides better discrimination of fault location, than, say, an impedance or distance relay. If the zones are too close, pilot wire may be the only feasible solution. .

Send your message to us

Galvanized Hanging Wire Roll for Installation of Suspended Drop Ceilings

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords