Galvanized Corrugated steel Plate for Roofing Type Galvanized steel Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

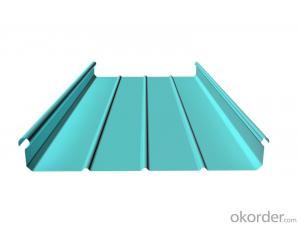

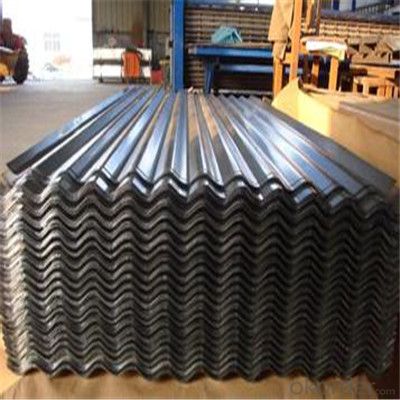

Description of Corrugated Iron Sheet:

The gloss can changeable by Customers' Request.we can also do some High gloss, with some sparkling granule in it.

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Residential - Row Houses, Bung alows, etc.

Commercial - Shopping Centers, Resorts, Hotels, etc.

Industrial - Porches, sloped roof slabs, etc.

Institutional - Colleges, School Building, etc.

Agriculture - Farm Houses, etc.

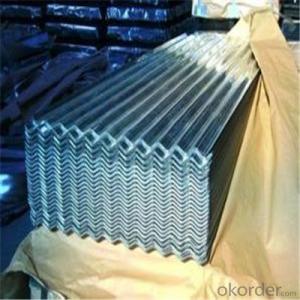

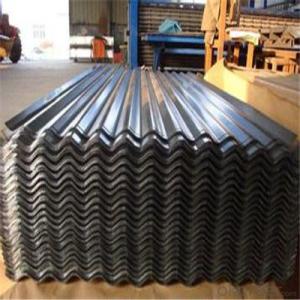

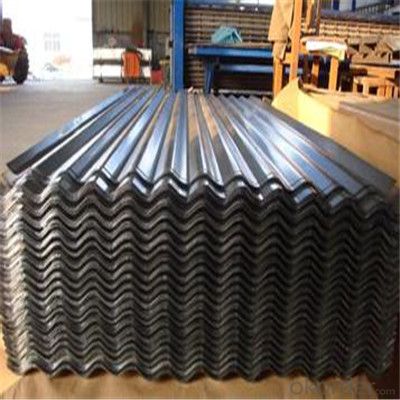

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Can steel sheets be used in electronics applications?

- Yes, steel sheets can be used in electronics applications, particularly for shielding purposes due to their excellent magnetic and electrical conductivity properties. However, they are less commonly used compared to other materials like aluminum or copper due to their higher weight and potential interference with electromagnetic fields.

- Q: Can steel sheets be used in architectural applications?

- Yes, steel sheets can be used in architectural applications. Steel sheets are versatile, durable, and offer structural integrity, making them suitable for various architectural uses such as roofing, cladding, and facades. Additionally, steel sheets can be easily shaped, allowing for creative and unique designs in architectural projects.

- Q: Are steel sheets suitable for outdoor applications?

- Yes, steel sheets are suitable for outdoor applications. Steel is highly durable, weather-resistant, and has excellent strength-to-weight ratio, making it a reliable and long-lasting material for various outdoor uses such as roofing, fencing, and cladding. Additionally, steel sheets can be coated or galvanized to provide additional protection against corrosion, further enhancing their suitability for outdoor environments.

- Q: Can steel sheets be used for manufacturing cutlery?

- Yes, steel sheets can be used for manufacturing cutlery. Steel is a common material used in the production of knives and other cutlery due to its strength, durability, and corrosion resistance. Steel sheets can be shaped, cut, and forged into various cutlery designs, ensuring the final product is sturdy and capable of cutting efficiently.

- Q: Can steel sheets be galvanized or coated with protective layers?

- Yes, steel sheets can be galvanized or coated with protective layers. Galvanizing is a process of applying a protective zinc coating to steel to prevent it from rusting. This is achieved by either hot-dip galvanizing, where the steel sheet is immersed in a bath of molten zinc, or by electroplating, which involves applying a zinc coating through an electrolytic process. In addition to galvanizing, steel sheets can also be coated with various protective layers. These coatings can include paint, epoxy, powder coatings, or other specialized coatings designed to enhance resistance to corrosion, chemicals, or abrasion. These protective coatings not only provide an aesthetic appeal but also serve as a barrier against environmental factors that could potentially damage the steel. The choice of galvanizing or coating a steel sheet depends on the specific application and the level of protection required. Galvanizing offers excellent corrosion resistance and is commonly used in outdoor applications where the steel is exposed to moisture, such as construction, automotive, and infrastructure industries. Coatings, on the other hand, provide a wide range of protective properties, making them suitable for various applications, including indoor environments or where specific chemical resistance is required. Ultimately, both galvanizing and coating steel sheets with protective layers are effective methods to enhance their durability and prolong their lifespan. The selection of the appropriate method depends on factors such as the intended use, environmental conditions, and budget.

- Q: What are the weight considerations for steel sheets?

- Weight considerations for steel sheets vary depending on the specific application and desired outcomes. Here are a few key points to consider: 1. Thickness: The thickness of a steel sheet greatly affects its weight. Thicker sheets generally weigh more, while thinner sheets weigh less. It is important to choose a thickness that meets the structural requirements of the project while considering weight limitations. 2. Strength requirements: Different applications require steel sheets of varying strength levels. High-strength steel sheets are often thicker and heavier, while lower strength sheets can be thinner and lighter. Understanding the strength requirements of the project is crucial in determining the appropriate weight of the steel sheets. 3. Transportation and handling: The weight of steel sheets impacts their ease of transportation and handling. Heavier sheets require more labor and equipment for lifting, loading, and unloading. Moreover, transport vehicles have weight limits that need to be considered when selecting steel sheet sizes. 4. Structural limitations: The weight of steel sheets can affect the overall structural design. In some cases, lighter sheets may be preferred to reduce the load on supporting structures. However, in other scenarios, heavier sheets may be necessary to provide the required strength and stability. 5. Cost considerations: The weight of steel sheets can also impact the overall cost of a project. Heavier sheets typically cost more due to the increased material required and the additional handling expenses. Therefore, it is essential to strike a balance between weight, cost, and performance to optimize the project's budget. Overall, weight considerations for steel sheets are crucial in determining the appropriate thickness, strength, transportation requirements, structural design, and cost-effectiveness of a project. By carefully evaluating these factors, one can select steel sheets that meet the specific needs while ensuring the optimal weight for the desired outcome.

- Q: What is the typical yield strength of stainless steel sheets?

- The yield strength of stainless steel sheets can vary based on factors such as the grade and thickness of the material. On average, stainless steel sheets possess a yield strength within the range of 30,000 to 80,000 psi. It should be noted that the yield strength differs among various grades of stainless steel, such as 304, 316, or 430. Moreover, the thickness of the sheet also impacts the yield strength, with thinner sheets generally exhibiting lower yield strengths when compared to thicker sheets. Therefore, it is advisable to refer to the manufacturer or supplier's specific grade and thickness specifications to ascertain the precise yield strength of a given stainless steel sheet.

- Q: What is the average lead time for ordering steel sheets?

- The average lead time for ordering steel sheets varies depending on the supplier and the specific circumstances, but it typically ranges from 1 to 4 weeks.

- Q: What is the maximum size available for steel sheets?

- The maximum size available for steel sheets can vary depending on the manufacturer and specific requirements, but commonly available sizes range from 4 feet by 8 feet (1.2 meters by 2.4 meters) to 6 feet by 20 feet (1.8 meters by 6.1 meters).

- Q: What are the different sheet metal stamping techniques for steel sheets?

- There are several sheet metal stamping techniques for steel sheets, including blanking, piercing, bending, deep drawing, and embossing.

Send your message to us

Galvanized Corrugated steel Plate for Roofing Type Galvanized steel Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords