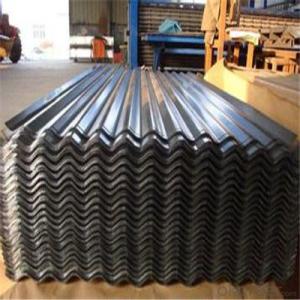

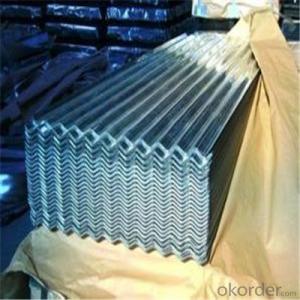

Galvanized Corrugated Steel for Roofings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:CUS-140527-K

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q235

Surface Treatment:Galvanized

Technique:Cold Rolled

Thickness:0.12-1.5mm

Zinc Coating:40-275G/M2

Surface Structure:Ero Spangle, Regular Spangle or Normal Spangle

Width:600-1250mm

Material:SGCC,Sgcd,Secc,Secd,Dx51d+Z

Export Markets:Global

Additional Info.

Packing:Export Packing

Standard:ISO9001/SGS/BV

Origin:Henan, China

HS Code:7210

Production Capacity:300000 Mt/Year

Product Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy ,strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications,

Hot-dip aluzinc steel sheet is substrated on cold rolled steel (CRC) in various strength and specification. Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

Specifications:

1. Thickness: 0.12-1.5mm

2. Width: 600-1250mm

3. Material: SGCC, SGCD, SECC, SECD, DX51D+Z

4. Zinc coating: 40-275G/M2

5. Surface Structure: Galvanized, zero spangle, regular spangle or normal spangle

6. Surface treatment: Chromated and oiled, chromated and non-oiled

Main characteristics:

1. Strong corrosion resistance

2. Surface quality

3. Conducive to deep processing, such as corrugated steel sheet 4. Economy and practicality

Packing

Each bare coil to be securely tied with two bands through the eye of coil (or not) and one circumferential, the contact points of these bands on the coil edge to be protect with edge protectors. Coil then to be properly wrapped with water proof /resistant paper, it then to be properly and completely metal wrapped. And each packed coil to be properly wrapped with band, three-six such band through the eye of coil at about equal distance, and two-four such bands securely tied around belly of coil at about equal distance.

| Commodity | Hot dip galvanized steel coil and sheet |

| Techinical Standard: | JIS 3302 / ASTM A653 / EN10143 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-1.5mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-275g/m2 |

| Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil |

| Package: | Properly packed for ocean freight exportation in 20''containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF |

| delivery time | 25 days after recepit of 30% TT |

| Remarks | Insurance is as requirements |

| MTC will be handed on with shipping documents | |

| We accept the third party certification test |

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: i have a question on a test and the questions before it are about blast furnace, wrought iron and cast iron...question 16 is..What is Steel?i dont really get what im being asked.. there could be many answers, what answer are they looking for?

- as steel is an alloy i thinkl they are looking for what elements it is made up of

- Q: Well the other day i told my friend that when you put a compass near steel it will screw up and he said only magnets do that then i showed him and it worked then he said: that'ss because steel has its own magnet in it coz it builds up static electricity is that correct what he said? thanks

- No. Steel does not build up static electricity by itself. Also, magnetic fields are made by moving electricity, not static electicity. The steel conducts magnetism, so it changes the earth's magnetic field near itself by conducting the field through itself. The larger effect is a magnet near a piece of steel: the compass has a magnet, and when you place it near a ferromagnetic material, it attracts. Try putting a refridgerator magnet against the fridge - it sticks because it attracts.

- Q: What is the maximum width of galvanized steel strip, please? The galvanized coat is 275, and how long is one coil?

- As far as I know, the galvanized rolls of WISCO are wider in width than other domestic steel mills, and can produce 2080 wide steel coils.

- Q: I am thinking about getting a cold steel tilite or a kershaw leek or possibly a buck sirus. If you have had any experience with these knives please give it to me. thanks

- You could argue that CS makes the tougher steel, but as was pointed out, none of their wares are made in the U.S. - if that doesn't matter, then go with the CS. I started with a CS Holdout II and ended up sending it back and going with a Kershaw (Ken Onion) Blur for EDC. My next knife will be a Benchmade- they are pricey but everyone I've ever spoken to about EDC knives tell me to go to Benchmade and no one else. Not one to just listen, I had to try out a few myself. Bought the wife a Kershaw Scallion...in purple, no less.

- Q: What are the different methods of shearing steel coils?

- There exist various approaches to shearing steel coils, each with its own unique pros and cons. Some of the most prevalent methods include: 1. Guillotine Shearing: This technique involves the use of a guillotine-like machine that vertically moves a blade to slice through the steel coil. Guillotine shearing provides high efficiency and accuracy, making it suitable for large-scale industrial production. However, it can lead to deformation or burrs on the cut edges. 2. Rotary Shearing: In rotary shearing, a set of rotating blades is employed to cut through the steel coil. This method enables continuous cutting, making it ideal for high-speed production lines. It ensures a clean and precise cut, but necessitates regular maintenance and blade sharpening. 3. Slitting: Slitting entails passing the steel coil through circular blades that create multiple parallel cuts. This method is commonly used to produce narrower strips from wider coils. It offers great precision and the ability to generate multiple strips simultaneously. However, slitting may result in edge burrs or camber on the strips. 4. Laser Cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the steel coil along a predetermined path. This method offers exceptional precision and can cut intricate shapes or patterns. It is commonly employed for specialized applications where accuracy is crucial, although it can be relatively costly. 5. Waterjet Cutting: Waterjet cutting employs a high-pressure stream of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can handle various materials and thicknesses. It is especially useful for cutting heat-sensitive materials or for applications requiring minimal distortion. 6. Plasma Cutting: Plasma cutting involves ionizing a gas to create a plasma arc that melts and blows away the steel coil. This method is fast and efficient, making it suitable for cutting thick steel coils. However, it may produce a wider heat-affected zone compared to other methods. 7. Electrical Discharge Machining (EDM): EDM employs electrical discharges to erode the steel coil and achieve the desired shape. This method is commonly used for intricate or delicate cutting tasks that demand high precision. It is particularly effective for hard materials. Each method of shearing steel coils possesses its own set of advantages and limitations, and the choice depends on factors such as the required precision, speed, material thickness, and the desired end-product.

- Q: What are the factors influencing the price of steel coils?

- The price of steel coils can be influenced by a variety of factors. These factors include: 1. Raw material costs: The cost of raw materials, such as iron ore and coal, directly affects the price of steel coils. Fluctuations in commodity prices can have a significant impact on the overall price. 2. Supply and demand: The balance between supply and demand in the steel industry plays a crucial role in determining the price of steel coils. If there is high demand, prices are likely to increase. Conversely, if there is an oversupply, prices may decrease. 3. Production and manufacturing costs: The cost of producing and manufacturing steel coils, including labor, energy, and transportation costs, can also impact the final price. Any changes in these costs can influence the overall price. 4. Currency exchange rates: The price of steel coils can be affected by fluctuations in currency exchange rates. If the currency in which steel is traded weakens against other currencies, it can result in higher prices. 5. Government regulations and policies: Government regulations, such as import tariffs, export restrictions, and environmental regulations, can impact the price of steel coils. These regulations can affect the cost of production and trade, ultimately influencing the price. 6. Market competition: The level of competition among steel manufacturers and suppliers can also impact the price of steel coils. If there are many suppliers and manufacturers, it can lead to competitive pricing and potentially lower prices. Conversely, if there are few suppliers dominating the market, prices may be higher. It is important to consider that these factors can vary over time and in different regions, which ultimately affects the pricing of steel coils in the market.

- Q: I want to save water $$, so I want to use frozen steel to cool my coke. possible or no?

- can't freeze it but ya can make it very cold

- Q: Why is the selection of steel building erector of extreme importance while starting a new steel building project?

- Steel building erectors play an important role as they are well versed with all the ups and downs of erecting a steel building and can prevent your construction project from unnecessary delays. There are lot of inexperienced steel building erectors in the market who can offer you their services at a much cheaper rate. Be cautious! It never works in the long run. A qualified steel building erector will always provide an initial professional insight of your project and cost effective solutions for your project.

- Q: How are steel coils inspected for width?

- To ensure compliance with the necessary specifications, various techniques are employed to inspect the width of steel coils. Among these methods, a commonly used one is the utilization of a caliper gauge, also referred to as a micrometer. This gauge makes direct contact with the coil edges to measure its width. The operator places the gauge at multiple points along the width and records the measurements. This approach guarantees precise measurements and facilitates the identification of any inconsistencies or deviations in the desired width. Another technique employed for width inspection is laser measurement. In this method, laser sensors are positioned on both sides of the coil, emitting a laser beam that scans across the width. By detecting the distance between the edges of the coil, the sensors provide accurate width measurements. This non-contact approach is highly efficient, swiftly inspecting the coil's width without causing any physical damage or requiring physical contact. Moreover, advanced systems employ computer vision technology for width inspection. This involves the use of cameras and image processing software to capture images of the coil's edges. The software then analyzes these images and calculates the width based on the detected edges. This method enables rapid inspections and can identify any irregularities in the coil's width. In conclusion, the inspection of steel coil width involves a combination of physical gauges, laser sensors, and computer vision technology. These methods ensure that the coils conform to the required width specifications and play a crucial role in maintaining quality control throughout the steel manufacturing process.

- Q: I am doing a experiment on mild steel soaked in sodium chlorideanyone can enlighten me about the effect of the sodium chloride in engineering term ?The mild steel specimen which I soaked in the sodium chloride has orange rust on it

- The mild steel contains a lot of Iron. The NaCl solution quickly attacks the iron content and forms rust. Over time, the solution may also cause what is called 'Chloride Cracking' of the steel. Pitting corrosion of stainless steel due to chlorides would certainly produce a rust-colored product. Passivation can be used to maintain a good corrosion resistant surface of stainless steel process vessel. There are many commercial products for this purpose. In the pharmaceutical industry, this process is often called derouging, that is to remove the buildup of iron oxides on the stainless steel process surfaces

Send your message to us

Galvanized Corrugated Steel for Roofings

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords