Galvanized Corrugated steel Plate for Roofing/Galvanized steel Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

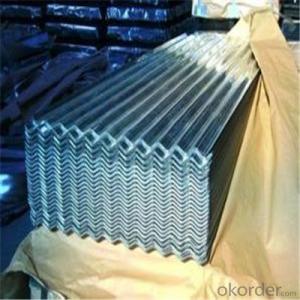

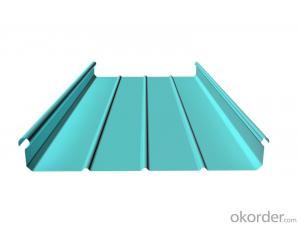

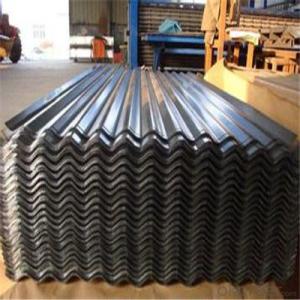

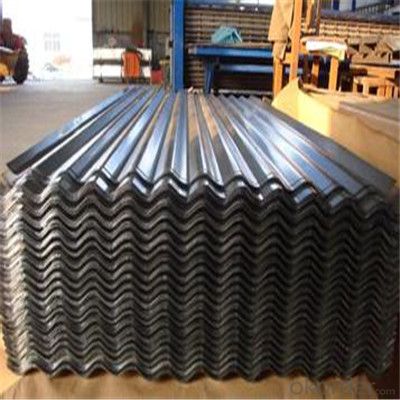

Description of Corrugated Iron Sheet:

most of corrugated board are cold-rolled sheet steel,after galvanized zinc or aluminium, paint layer to suppress into finished products and the width is generally 600-1200mm, dedicated to building roof, walls retaining plate.

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

wall panel and ceiling board, etc.At the same time of using corrugated plate, using color steel plate do some wall decoration to make the building’s decoration effect looks new and unique.

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Are steel sheets suitable for data center infrastructure?

- Indeed, data center infrastructure can rely on steel sheets. The utilization of steel sheets in the establishment of data centers is prevalent because of their exceptional robustness, longevity, and resistance to fire. Furthermore, they furnish essential support for the infrastructure, encompassing server racks, cabinets, and raised flooring systems. Not only do steel sheets safeguard data center equipment against potential dangers such as electromagnetic interference (EMI) and physical harm, but they can also be conveniently tailored and adapted to suit the precise demands of a data center. This adaptability renders them a favored option for constructing data center infrastructure.

- Q: What is the cost of steel sheets?

- The cost of steel sheets can vary depending on various factors such as size, thickness, grade, and market conditions. It is recommended to contact suppliers or check current market prices for accurate and up-to-date information.

- Q: What are the different methods of joining steel sheets together?

- There exists a variety of techniques for connecting steel sheets, each possessing unique benefits and applications. Some commonly employed techniques include: 1. Welding: Utilized extensively, welding effectively joins steel sheets by melting their edges and fusing them together through the application of heat. Different welding processes, including arc welding, gas welding, and spot welding, are available, each tailored to specific applications. 2. Riveting: Riveting, a mechanical method, utilizes metal fasteners called rivets to connect steel sheets. Rivets are inserted into pre-drilled holes in the sheets and secured in place by hammering or pressing. Riveting is renowned for producing robust and long-lasting joints. 3. Bolting: Bolting employs bolts and nuts to hold steel sheets together. Holes are drilled through the sheets, and bolts are inserted from one side, with nuts tightened on the other side to secure the joint. Bolting offers the advantages of being quick, easy to assemble, and allows for disassembly if necessary. 4. Adhesive bonding: Adhesive bonding employs specialized adhesives to join steel sheets. The adhesive is applied between the surfaces to be joined and forms a strong bond as it cures. This method is commonly employed in industries where welding may distort the materials or is not feasible due to the specific materials involved. 5. Mechanical fastening: Mechanical fasteners such as screws, self-tapping screws, or nails may be used to join steel sheets. These fasteners create a sturdy connection by penetrating the sheets and holding them in place. Mechanical fastening is relatively swift and does not necessitate any specialized equipment. 6. Clinching: Clinching is a cold forming process that connects steel sheets by deforming the material without the use of external heat. It involves pressing the sheets together and forming a mechanical interlock. Clinching is frequently employed in the automotive industry due to its high-speed production capabilities and joint strength. Each technique possesses its own advantages based on factors such as joint strength, ease of assembly, cost, and specific application requirements. The selection of a joining technique depends on the intended purpose of the joint, material properties, and the environmental conditions to which the joint will be exposed.

- Q: What is the average cost of steel sheets per square foot?

- The cost of steel sheets per square foot can differ significantly due to various factors, including the type of steel, thickness, size, and market conditions. Nevertheless, as of 2021, the price range for steel sheets averages from $5 to $20 per square foot. It is crucial to acknowledge that this estimate is broad, and prices may vary depending on the location, supplier, and other market aspects. Consequently, it is advisable to collect quotes from multiple suppliers in order to obtain an accurate and current cost for steel sheets per square foot.

- Q: Can steel sheets be used for walkways or platforms?

- Yes, steel sheets can be used for walkways or platforms. Steel sheets are commonly used in industrial and commercial settings due to their durability, strength, and resistance to various environmental factors. They can be fabricated and installed to create sturdy walkways or platforms that can withstand heavy foot traffic or even the movement of equipment and machinery. Steel sheets can also be customized to meet specific design requirements such as non-slip surfaces, raised edges for safety, or perforations for drainage. Additionally, steel sheets are relatively low maintenance and can be easily cleaned and maintained, making them an ideal choice for walkways or platforms in various applications including factories, warehouses, construction sites, and even outdoor areas.

- Q: What are the different types of steel alloys used for sheets?

- There are several types of steel alloys commonly used for sheets, including carbon steel, stainless steel, galvanized steel, and alloy steel.

- Q: Can steel sheets be used for electrical enclosures or cabinets?

- Yes, steel sheets can be used for electrical enclosures or cabinets. Steel is a commonly used material for such applications due to its strength, durability, and ability to protect electrical components from external factors such as moisture and impact.

- Q: How do you store steel sheets to prevent damage?

- To prevent damage to steel sheets, it is recommended to store them in a dry, well-ventilated area, away from moisture or humidity. They should be stored horizontally on a flat surface, with adequate support to prevent bending or warping. Additionally, using protective covers or separators between each sheet can help prevent scratches or surface damage.

- Q: Can steel sheets be used for agricultural equipment?

- Agricultural equipment can indeed utilize steel sheets. Steel, a flexible and long-lasting substance, is frequently employed in the construction of diverse agricultural machinery and equipment. Its notable features include robustness, rigidity, and resistance against wear and tear, which make it ideal for demanding tasks in the farming and agriculture sectors. Steel sheets can be utilized to produce a wide range of agricultural equipment, including plows, cultivators, seeders, harvesters, trailers, and storage containers. These tools necessitate durable materials that can withstand the challenging conditions of the agricultural environment, including exposure to soil, moisture, and heavy loads. Steel sheets are capable of being shaped and manipulated into various forms and sizes, thus allowing for the customization of agricultural equipment to meet specific requirements. Furthermore, steel can be easily welded, ensuring the structural integrity of the equipment and facilitating repairs, if needed. Moreover, steel sheets can undergo coating or galvanization to enhance their resistance against corrosion. This additional measure further augments their longevity and durability when employed in agricultural applications. Consequently, the equipment is safeguarded against rust and deterioration brought about by exposure to diverse weather conditions and chemicals typically found in farming activities. In summary, steel sheets represent a suitable material for agricultural equipment due to their strength, durability, and versatility. Their incorporation into the production of agricultural machinery guarantees dependable and efficient performance, thereby contributing to the productivity and success of farming operations.

- Q: What is the average bending radius for steel sheets?

- The average bending radius for steel sheets can vary depending on the thickness and type of steel being used. However, a common range for the average bending radius of steel sheets is between 0.5 to 2 times the thickness of the sheet.

Send your message to us

Galvanized Corrugated steel Plate for Roofing/Galvanized steel Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords