Galvanized Corrugated Steel Sheet for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

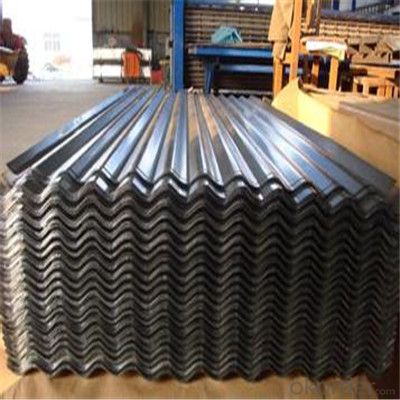

Description of Corrugated Iron Sheet:

The Roof and Wall sheets are manufactured from zinc/ aluminum alloy coated high tensile steel. The sheets are available in attractive range of colours.

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Wall is one of the widest wall profile sheet available, which is also quick and easy to install

Long lasting: Zinc – Aluminum alloy coating and superior paint system gives longer product life – almost 2 to 4 times longer than ordinary colour coated sheets.

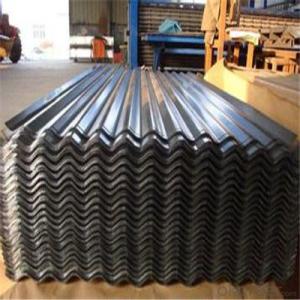

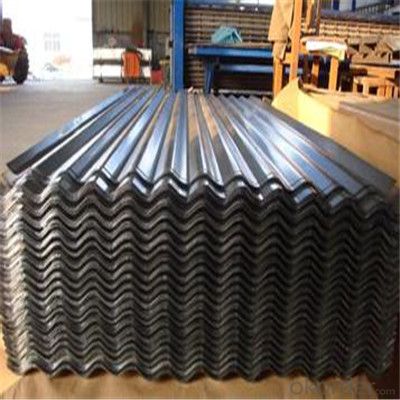

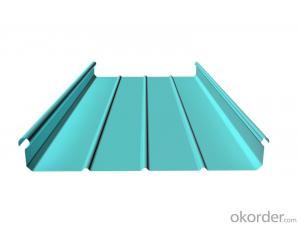

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: Are steel sheets suitable for decorative applications?

- Yes, steel sheets are suitable for decorative applications. They can be easily shaped, cut, and finished to create various decorative elements such as wall panels, furniture, sculptures, and architectural features. Steel sheets also offer durability, strength, and a modern aesthetic, making them a popular choice for decorative purposes.

- Q: What is the difference between a black and pickled steel sheet?

- Distinguishing a black steel sheet from a pickled steel sheet primarily lies in their surface finish and the processes they undergo. To begin with, a black steel sheet, also referred to as hot-rolled steel, is manufactured through a technique known as hot rolling. In this procedure, the steel is heated beyond its recrystallization temperature and passed through rollers to achieve the desired thickness. Consequently, the resulting sheet exhibits a dark, rough, and scaly surface, which is why it is referred to as "black steel." The dark appearance is a consequence of the oxidation that transpires during the hot rolling process. On the contrary, a pickled steel sheet is produced by means of pickling. Following the hot rolling stage, the black steel sheet undergoes a treatment where it is immersed in an acidic solution, typically hydrochloric acid or sulfuric acid. This pickling process eradicates the oxide scale from the surface of the black steel sheet, resulting in a smooth and clean surface. Additionally, the pickling process aids in enhancing the steel's resistance to corrosion. The selection between a black steel sheet and a pickled steel sheet is contingent upon the intended application. Black steel sheets are often favored for structural components, such as beams and columns, where the surface appearance is not a crucial factor. On the other hand, pickled steel sheets, with their smooth and clean surface, are commonly utilized in applications that demand a high-quality finish, such as automotive panels, appliances, and architectural elements. In conclusion, the primary disparity between a black steel sheet and a pickled steel sheet lies in their surface finish. A black steel sheet possesses a rough and scaly surface due to oxidation during hot rolling, while a pickled steel sheet exhibits a smooth and clean surface subsequent to undergoing a pickling process to eliminate the oxide scale.

- Q: Are steel sheets available in custom sizes?

- Yes, steel sheets are available in custom sizes.

- Q: What is the difference between hot dipped galvanized and electro galvanized steel sheets?

- The main difference between hot dipped galvanized and electro galvanized steel sheets lies in the process of coating. Hot-dipped galvanized steel sheets are coated by immersing them in a bath of molten zinc, which creates a thicker and more durable layer of zinc compared to electro galvanized steel sheets. On the other hand, electro galvanized steel sheets are coated by an electrolytic process, where a thin layer of zinc is applied to the steel surface. This makes electro galvanized steel sheets more suitable for applications that require a thinner coating and a smoother finish, while hot-dipped galvanized steel sheets provide excellent corrosion resistance and are often used in more heavy-duty applications.

- Q: Can steel sheets be used for heat exchangers or boilers?

- Yes, steel sheets can be used for heat exchangers or boilers. Steel is a commonly used material in the construction of heat exchangers and boilers due to its high strength, durability, and resistance to corrosion at high temperatures. Additionally, steel sheets can be easily formed and welded to create the required shapes and structures for efficient heat transfer.

- Q: Can steel sheets be used in electrical applications?

- Yes, steel sheets can be used in electrical applications. They are commonly used as magnetic cores in transformers and other electrical machines. Additionally, steel sheets are often used as a protective casing or enclosure for electrical equipment.

- Q: Can Q460C steel plate be used as Q235 steel plate?

- The mechanical properties of the same structure require that the Q460C can reduce the thickness of the material used and reduce the weight of the structure without changing the mechanical properties, without reducing the strength of the base metal and the service life of the workpiece. Reduce the number of welded structures.High strength steel instead of ordinary low carbon structural steel is the current trend.

- Q: Can steel sheets be recycled multiple times?

- Yes, steel sheets can be recycled multiple times. Steel is one of the most recycled materials in the world due to its durability and recyclability. When steel sheets reach the end of their useful life, they can be collected, melted down, and reprocessed into new steel products. This process can be repeated numerous times without compromising the quality of the steel. Recycling steel sheets not only conserves natural resources but also reduces energy consumption and greenhouse gas emissions associated with the production of new steel.

- Q: What are the different sheet metal bending techniques for steel sheets?

- There are several sheet metal bending techniques for steel sheets, including air bending, bottoming, coining, and folding. Air bending involves applying force to the sheet metal to bend it using a V-shaped punch and a V-shaped die, without touching the bottom of the die. Bottoming involves bending the sheet metal until it comes into full contact with the bottom of the die, resulting in a tighter bend radius. Coining is a precision bending technique that uses a punch and a die to create a highly accurate and crisp bend. Folding, on the other hand, involves bending the sheet metal at a specific angle using a press brake or a folding machine. These techniques offer various options for achieving different bending requirements in steel sheet fabrication.

- Q: How are steel sheets transported?

- Steel sheets are typically transported using various methods, depending on the quantity, size, and destination. One common method is by truck, where the steel sheets are loaded onto flatbed trailers or enclosed trucks. This allows for easy transportation and flexibility in reaching different locations. For larger quantities or long-distance transportation, steel sheets can be transported by rail. They are usually loaded onto specialized railcars designed to securely hold and transport heavy loads. Rail transportation is efficient for long distances and can handle larger volumes of steel sheets. In some cases, steel sheets may also be transported by sea. They are loaded onto shipping containers or directly onto ships designed for bulk cargo. This method is usually used for international shipments or when transporting large quantities of steel sheets across long distances. Regardless of the transportation method, it is crucial to ensure that the steel sheets are properly secured and protected during transit to prevent damage or loss. This may involve using straps, chains, or other securing devices to hold the sheets in place and protect them from shifting or external factors such as weather conditions. Overall, the transportation of steel sheets requires careful planning and coordination to ensure safe and efficient delivery to their intended destination.

Send your message to us

Galvanized Corrugated Steel Sheet for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords