Prime quantity Cold Rolled Steel Coils/Sheets, CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Name | Cold Rolled Sheet Coil |

Material | SPCC/SPCD/SPCE/DC01/ST12/ ST14/SPCD/DC03/DC04 ect. |

Grade Standard | JIS G3302, EN10142, ASTM653, ASTM95 |

Thickness | 0.15-3.5mm |

Width | 600mm-1500mm |

Coil ID | 508-610mm |

Coil OD | max 1500mm |

Weight | 3-10 Tons |

Tolerance | Thickness tolerance:+/-0.02mm; Width tolerance:+/-5mm |

Surface | No-skin passed or Skin passed, Tensile leveled |

Surface Treatment | Chromate/Unchromate passivation, fingerprint resistant treatment, oiled/unoiled |

Annual Output | 350,000MT |

Application | Construction, hardware, home applicances, interior decoration |

General Application of Cold Rolled Steel Coil:

Classification | Designation | Characteristics | Main applications |

Commercial quality | SPCC SPCCT | Commercial quality suitable for bending fabrication and simple forming; this is the type in greatest demand. | Refrigerators, cabinets, power distribution baords and drums. |

Drawing quality | SPCD | Drawing quality second only to that of SPCEN. Excellent uniformity. | Automobile floor and roof panels. |

Deep-drawing quality | SPCE SPCF | Deep-drawing quality.With metallurgically controlled grain size, it retains its beautiful finish even after being deep-drawn. | Automobile fenders and quarter panels |

Extra deep-drawing quality | SPCG | Extra-low-carbon steel sheets with highest workability | Automobile internal panels and deep-drawn parts |

Specification

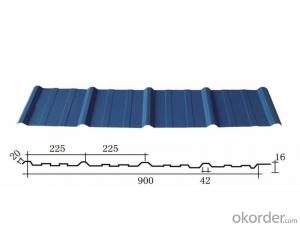

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508 & 610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

St12 | ≤0.10 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

St13 | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

St14 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness <0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q: Can steel sheets be used in transportation applications?

- Yes, steel sheets can be used in transportation applications.

- Q: Can steel sheets be used for signage purposes?

- Indeed, signage purposes can be served by steel sheets. Their durability allows them to withstand harsh weather conditions, rendering them appropriate for outdoor signage. Various sizes and designs can be achieved by cutting, shaping, and welding the steel sheets, offering versatility in crafting personalized signage. To enhance aesthetics and ensure long-lasting quality, the steel sheets can be painted or coated with different finishes. Moreover, their sturdiness enables secure mounting, making them an excellent choice for large and heavy signage installations.

- Q: Can the steel sheets be painted or coated?

- Indeed, it is possible to paint or coat steel sheets. Diverse industries often engage in the practice of painting or coating steel sheets to enhance visual appeal, guard against corrosion, and bolster durability. Prior to any application of paint or coating, it is crucial to thoroughly cleanse and prepare the steel surface to ensure proper adhesion. The choice of paint or coating depends on the desired finish, environmental conditions, and specific application. It is imperative to select a paint or coating that is compatible with the steel substrate and capable of enduring the intended use and exposure to chemicals, moisture, UV radiation, or other factors that may impact the performance and lifespan of the coating.

- Q: What are the different types of steel sheet finishes for architectural applications?

- There are several types of steel sheet finishes commonly used in architectural applications, including hot rolled, cold rolled, galvanized, and stainless steel. Each finish has its own unique properties and aesthetic appeal, allowing architects to choose the most suitable option based on their specific design requirements.

- Q: How long do steel sheets last?

- The lifespan of steel sheets can vary depending on various factors such as the quality of the steel, the environment in which they are used, and the maintenance provided. However, with proper care and maintenance, steel sheets can last for several decades, if not longer.

- Q: Can steel sheets be used for soundproofing purposes?

- Yes, steel sheets can be used for soundproofing purposes. They have good density and mass, which helps to block and absorb sound waves. Steel sheets can be effective in reducing noise transmission when properly installed and combined with other soundproofing materials like insulation or acoustic panels.

- Q: What are the common applications of steel sheets?

- Steel sheets are commonly used in a wide range of applications such as automotive manufacturing, construction, infrastructure projects, appliances, shipbuilding, and the production of various metal components.

- Q: Do steel sheets require any special maintenance?

- Yes, steel sheets require some special maintenance to ensure their longevity and performance. Regular inspection and cleaning are necessary to prevent the build-up of dirt, debris, and corrosion. Additionally, applying protective coatings or paint can help to protect the steel from rust and other damages. Proper storage and handling, such as avoiding exposure to moisture and extreme temperatures, are also important to maintain the quality of steel sheets.

- Q: Are the steel sheets suitable for HVAC ductwork?

- Yes, steel sheets are suitable for HVAC ductwork. Steel is a durable and strong material that can withstand the pressure and temperature changes typical in HVAC systems. It has excellent fire resistance properties and is resistant to corrosion, making it ideal for ductwork applications. Additionally, steel sheets can be easily fabricated and formed into various shapes and sizes to fit specific ductwork requirements. Therefore, steel sheets are a reliable and commonly used material in the construction of HVAC ductwork.

- Q: Steel plate pile length, adjacent two steel plate pile joints should be staggered what position?

- If the joint in the same position, such as 9+9m then need to stagger joint position,Avoid stress in one position that results in joint fracture and deformation risk.

Send your message to us

Prime quantity Cold Rolled Steel Coils/Sheets, CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords