Galvanized Corrugated Iron Sheet for Roofing Supplied from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

Thickness: 0.14-0.8mm

Weight of each package: about 4.1mt

Width: 600mm-1250mmWidth tolerance:-0/+3mm

Specifications of Corrugated Iron Sheet:

| Product Name | Wave Tile |

| Standard: | GB , ASTM , JIS etc |

| Raw Material | GI , GL , PPGI , PPGL |

| Thickness | 0.15mm-0.6mm |

| Width | 750mm-1000mm(BC)/665-920mm(AC) |

| Length | 4000mm(Max) |

| Coating | AZ40-AZ160g , Z50-Z140g |

| Temper | Full hard , half hard , annealed |

| Spangle | Regular , Minimized , Big spangle |

| Pallet Weight: | 2-4mt |

| Material | SGCH , SGLCH , SGCC |

| Payment: | Trade Assurance OF Alibaba ,T/T, L/C at sight |

| MOQ: | 20 ton each size, 1x20'ft per delivery |

Features of Corrugated Iron Sheet:

Surface treatment: chromate, oil/unoil, bright finish, spangle,

Corrugated Sheet Materials: Galvanized steel, Aluzinc Steel, Aluzinc Pre-painted sheet and Aluminium sheet. Gloss: The gloss can changeable by Customers' Request.we can also do some High gloss, with some sparkling granule in it.

Paint type: PE or PVDF

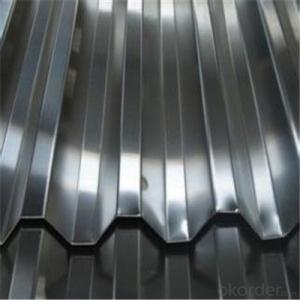

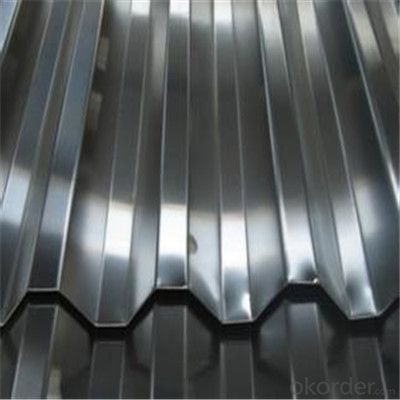

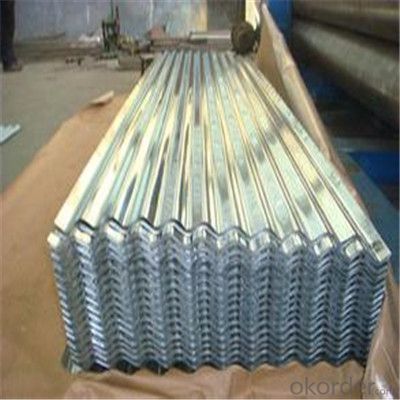

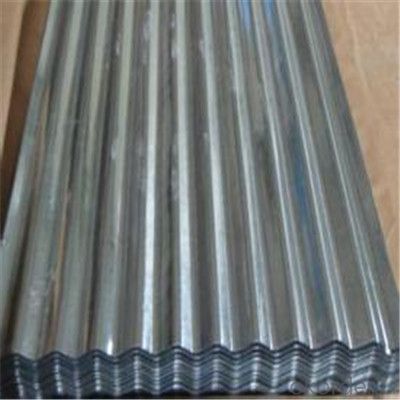

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What is the average price per square meter of steel sheets?

- The average price per square meter of steel sheets can vary depending on various factors such as the type, thickness, quantity, and current market conditions. It is recommended to consult with suppliers or conduct market research to get the most accurate and up-to-date pricing information.

- Q: What are the common applications of cold-rolled steel sheets?

- Cold-rolled steel sheets are commonly used in various industries for applications such as automotive components, appliances, construction materials, machinery, and electrical equipment.

- Q: How do steel sheets perform in terms of chemical resistance?

- Steel sheets generally have good chemical resistance due to their high corrosion resistance. However, their exact performance can vary depending on the specific type of steel and the chemicals they come into contact with.

- Q: What are the driving methods for steel sheet piles?

- Mechanical hand general construction pile length of less than 12m steel pile; more than 12m length generally use crawler crane combined with vibration hammer construction, if the surrounding environment is sensitive to vibration, can use Japanese static pressure pile driving machine construction. The vibration hammer: DZ40 DZ45DZ60 DZ90 DZJ120; ordinary steel sheet pile, DZ60 type vibrating hammer.

- Q: What is the average yield strength of steel sheets?

- The average yield strength of steel sheets varies depending on the specific grade and thickness of the steel. However, it typically ranges from 250 to 400 megapascals (MPa).

- Q: What are the properties of steel sheets?

- Steel sheets have a number of properties that make them highly desirable in various industries. Firstly, steel sheets are known for their exceptional strength and durability. They can withstand heavy loads and have a high resistance to impact and deformation. This makes them ideal for applications where strength is crucial, such as construction, automotive, and aerospace industries. Another important property of steel sheets is their excellent corrosion resistance. Steel is typically coated with a thin layer of zinc or other protective materials to prevent rusting and corrosion. This protective coating enhances the longevity of steel sheets, allowing them to be used in outdoor or humid environments without the risk of degradation. Steel sheets are also known for their versatility. They can be easily bent, shaped, and welded, which makes them suitable for various fabrication processes. This adaptability enables manufacturers to create complex structures and components with ease, making steel sheets a popular choice in architectural and industrial designs. Furthermore, steel sheets have excellent thermal conductivity. This property allows them to efficiently transfer and distribute heat, making them ideal for applications where temperature regulation is required, such as in heating systems or electrical appliances. Lastly, steel sheets are highly recyclable, making them an environmentally-friendly choice. Steel is one of the most recycled materials in the world, and the recycling process does not compromise its properties or quality. This sustainability factor makes steel sheets a preferred option for those looking for eco-friendly materials. In summary, the properties of steel sheets include strength, durability, corrosion resistance, versatility, thermal conductivity, and recyclability. These qualities make steel sheets a reliable and versatile material for various industries and applications.

- Q: Can steel sheets be used for electrical enclosures?

- Yes, steel sheets can be used for electrical enclosures. Steel is a common material choice for enclosures due to its durability, strength, and ability to provide adequate protection against external factors such as moisture, dust, and impact. Additionally, steel can be easily customized and offers good electromagnetic shielding properties, making it suitable for housing electrical components and systems.

- Q: What is the difference between an open plate and an original plate?

- Open plate and the original plate are many industries are commonly used plate, although the appearance of such two plates are very similar, but there are other essential differences, these we all want to clear.x0d

- Q: Are steel sheets suitable for exterior cladding?

- Yes, steel sheets are suitable for exterior cladding. They are durable, weather-resistant, and provide a sleek and modern appearance to buildings. Additionally, steel sheets offer great strength and can withstand harsh environmental conditions, making them a reliable choice for exterior applications.

- Q: What is the difference between a smooth and expanded metal steel sheet?

- A smooth metal steel sheet has a flat surface with no perforations or raised patterns, while an expanded metal steel sheet has a textured surface with small diamond-shaped openings that are created by stretching the metal.

Send your message to us

Galvanized Corrugated Iron Sheet for Roofing Supplied from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords