Frp Roof Panels - Corrosion Resistance FRP Roofing Tile Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATION

Name | FRP Roofing |

Material | Fiberglass |

Width | 880mm/1050mm |

Effective width | 800mm/960mm |

Wave length | 160mm |

Wave height | 30mm |

Pitch | 220mm |

Thickness | 3/2.5mm |

Length | Customized but must be a multiple of wave pitch |

Color | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ | 1000 Square meter |

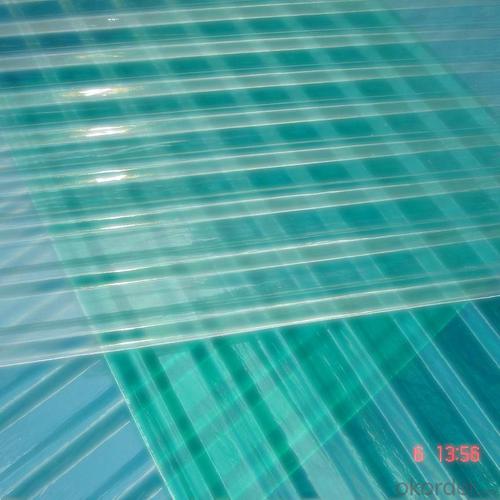

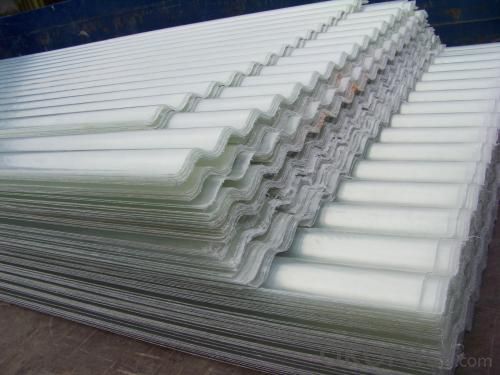

PICTURES

- Q: Are FRP roofing panels compatible with different roofing membranes or liners?

- No, FRP (Fiberglass Reinforced Plastic) roofing panels are not compatible with different roofing membranes or liners. FRP panels are typically used as a standalone roofing system and are not designed to be installed over or in conjunction with other materials.

- Q: Can FRP roofing panels be used in concert venues or stadiums?

- Yes, FRP roofing panels can be used in concert venues or stadiums. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and weather-resistant, making them suitable for large structures like concert venues or stadiums. They offer excellent strength and can withstand the elements, making them a reliable choice for such applications. Additionally, FRP panels can be easily customized to fit the specific design requirements of the venue or stadium.

- Q: Can FRP roofing panels be used for outdoor structures?

- Yes, FRP (Fiber Reinforced Plastic) roofing panels can be used for outdoor structures. FRP roofing panels are known for their durability, strength, and resistance to weather elements such as UV rays, rain, and wind. These panels are designed to withstand harsh outdoor conditions and provide excellent protection for various structures. They are commonly used for outdoor applications such as patios, pergolas, carports, sheds, and agricultural buildings. In addition to their weather resistance, FRP roofing panels are also lightweight, easy to install, and have a long lifespan. Overall, FRP roofing panels are a reliable and practical choice for outdoor structures.

- Q: Can FRP roofing panels be used for skylights?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for skylights. FRP panels are lightweight, durable, and provide excellent light transmission, making them a popular choice for skylight applications. They are designed to be weather-resistant, UV-stable, and can withstand extreme temperatures, making them suitable for outdoor use. Additionally, FRP panels are available in various colors and profiles, allowing for customization and aesthetic integration with the surrounding roofing system. However, it is important to ensure that the FRP panels used for skylights are specifically designed and certified for this purpose, as they may have additional features such as enhanced impact resistance or light diffusion properties to optimize their performance as skylights.

- Q: Are FRP roofing panels resistant to impact damage?

- Yes, FRP roofing panels are known for their excellent resistance to impact damage.

- Q: Are FRP roofing panels resistant to cracking?

- Yes, FRP roofing panels are resistant to cracking.

- Q: Can FRP roofing panels be used for sound barriers?

- Yes, FRP roofing panels can be used for sound barriers. The high-strength and durable nature of FRP panels make them effective in reducing and dampening sound transmission. Additionally, their lightweight construction and ease of installation make them a practical choice for sound barrier applications.

- Q: Are FRP roofing panels suitable for military buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for military buildings. FRP roofing panels are a popular choice for military buildings due to their durability, strength, and resistance to various weather conditions. These panels are lightweight, yet offer exceptional structural integrity, making them ideal for military buildings that require strength and reliability. FRP roofing panels are also known for their resistance to corrosion, chemicals, and UV rays, which are important factors for military buildings located in harsh environments. They can withstand extreme temperatures, heavy impacts, and high winds, ensuring the safety and longevity of the buildings. Additionally, FRP roofing panels are easy to install and maintain, making them cost-effective in the long run. They require minimal maintenance and do not require regular painting or coating, reducing the overall maintenance costs and efforts for military buildings. Furthermore, FRP roofing panels offer excellent insulation properties, providing thermal efficiency and noise reduction. This is particularly beneficial for military buildings where temperature control and soundproofing are essential, such as command centers, barracks, or training facilities. Overall, FRP roofing panels are a suitable choice for military buildings due to their durability, strength, resistance to various elements, ease of installation and maintenance, as well as their insulation properties. They offer reliable protection and long-lasting performance, making them an ideal roofing solution for military facilities.

- Q: Are FRP roofing panels resistant to lightning strikes?

- FRP roofing panels, which are also known as fiberglass reinforced plastic panels, do not possess inherent resistance against lightning strikes. Nevertheless, they are regarded as safer compared to alternative roofing materials like metal or asphalt. The rationale behind this is that FRP roofing panels are non-conductive, signifying that they do not facilitate the flow of electricity. Consequently, if lightning were to strike a structure with FRP roofing panels, the panels themselves would not attract or transmit the electrical charge of the lightning bolt. However, it is crucial to acknowledge that lightning can still present a risk to any structure, irrespective of the roofing material. Lightning seeks the path of least resistance to the ground and can travel through any conductive material, such as metal pipes or wiring, present within the building. To mitigate the risk of lightning strikes, it is advisable to install a lightning protection system. This system commonly incorporates lightning rods or air terminals placed at the highest points of the structure, along with conductive cables that run down the building and into the ground. These components aid in safely diverting the electrical charge of a lightning strike away from the structure and into the ground. In conclusion, although FRP roofing panels lack resistance against lightning strikes, they are deemed safer than certain other roofing materials due to their non-conductive properties. Nonetheless, it is imperative to implement appropriate lightning protection measures to ensure the safety of any structure, regardless of the roofing material employed.

- Q: Are FRP roofing panels compatible with different roofing adhesives or sealants?

- Yes, FRP (Fiberglass Reinforced Polymer) roofing panels are generally compatible with a variety of roofing adhesives and sealants. However, it is important to note that the specific compatibility may vary depending on the manufacturer and type of adhesive or sealant being used. It is recommended to consult the manufacturer's guidelines or contact their customer support to ensure compatibility before applying any adhesive or sealant to FRP roofing panels. Additionally, it is crucial to follow proper installation techniques and guidelines provided by the manufacturer to ensure a secure and long-lasting bond between the panels and the adhesives or sealants.

Send your message to us

Frp Roof Panels - Corrosion Resistance FRP Roofing Tile Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords