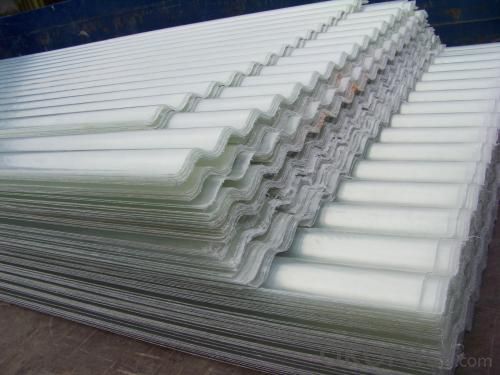

High-Quality FRP Roofing Panel for Corrosion-Resistant Roofing Tile and Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATION

Name | FRP Roofing |

Material | Fiberglass |

Width | 880mm/1050mm |

Effective width | 800mm/960mm |

Wave length | 160mm |

Wave height | 30mm |

Pitch | 220mm |

Thickness | 3/2.5mm |

Length | Customized but must be a multiple of wave pitch |

Color | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ | 1000 Square meter |

PICTURES

- Q: Do FRP roofing panels require any special tools for installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels typically require some special tools for installation. These tools may include a power drill with appropriate bits, a circular saw or a jigsaw for cutting the panels to size, a tape measure, a level, a ladder or scaffolding for accessing the roof, a caulking gun for applying sealant, and roofing nails or screws for securing the panels to the roof structure. Additionally, a safety harness and appropriate personal protective equipment, such as gloves and safety glasses, should be used during the installation process. It is important to consult the manufacturer's instructions and guidelines to determine the specific tools required for the installation of FRP roofing panels, as the requirements may vary depending on the panel design and installation method.

- Q: Can FRP roofing panels be used for skylights in zoos?

- Yes, FRP roofing panels can be used for skylights in zoos.

- Q: Are FRP roofing panels suitable for retail kiosks or booths?

- FRP roofing panels, also known as fiberglass reinforced plastic, are an excellent option for retail kiosks or booths. Their versatility and durability make them a popular choice in construction. With a range of benefits, FRP roofing panels are well-suited for retail structures. Firstly, FRP roofing panels are lightweight, making installation and transportation easy. This is particularly advantageous for retail kiosks or booths that may need to be relocated or set up in different locations. The lightweight nature of these panels also reduces the load on the structure, which is beneficial for temporary or portable retail setups. Secondly, FRP roofing panels are highly resistant to corrosion, weather, and impact. This makes them ideal for outdoor retail kiosks or booths exposed to various environmental elements. The durability of FRP panels ensures they can withstand harsh weather conditions, including heavy rain, strong winds, and extreme temperatures. Additionally, FRP roofing panels offer a variety of colors and finishes, allowing for customization to match the aesthetics of the retail kiosk or booth. This versatility in design options enables retailers to create an appealing and attractive visual appearance that can attract customers. Moreover, FRP roofing panels provide good insulation properties, helping to maintain a comfortable temperature inside the retail kiosk or booth and reducing the reliance on heating or cooling systems. This can result in energy savings and a more pleasant shopping experience for customers. In conclusion, FRP roofing panels are a suitable choice for retail kiosks or booths due to their lightweight, durable, weather-resistant, customizable, and insulating properties. These panels provide a reliable and visually appealing roofing solution for retail structures, ensuring the comfort and safety of both retailers and customers.

- Q: Can FRP roofing panels be used for solariums?

- Solariums can indeed utilize FRP roofing panels. FRP, an acronym for fiberglass reinforced panels, is a well-liked roofing option due to its lightweight, durability, and resistance to weather conditions. These panels are specifically designed to endure harsh weather and are frequently utilized in commercial and industrial settings. When it comes to solariums, FRP panels offer numerous benefits. They enable the passage of natural light, resulting in a bright and inviting atmosphere. Moreover, these panels provide excellent insulation, ensuring a comfortable temperature within the solarium. Additionally, FRP panels are resistant to UV rays, safeguarding furniture and plants from fading or damage. It is crucial to highlight that the design and installation of FRP roofing panels for solariums should be carried out by experienced professionals well-versed in both roofing and solarium construction. Proper installation techniques, including joint sealing and ensuring adequate drainage, are vital to prevent leaks and water damage. To conclude, FRP roofing panels are a suitable choice for solariums due to their durability, resistance to weather conditions, insulation properties, and ability to allow natural light into the space. Nonetheless, professional installation is imperative to ensure the panels are correctly installed and sealed, minimizing any potential issues.

- Q: Are FRP roofing panels suitable for residential applications?

- Yes, FRP roofing panels are suitable for residential applications. They offer durability, weather resistance, and are lightweight, making them a practical and cost-effective choice for residential roofs. Additionally, FRP panels can be easily installed and require minimal maintenance, making them a convenient option for homeowners.

- Q: Are FRP roofing panels resistant to damage from ice or snow?

- Yes, FRP roofing panels are generally resistant to damage from ice or snow. FRP stands for Fiberglass Reinforced Panels, which are composed of a strong and durable fiberglass material. This material is known for its exceptional strength and ability to withstand various weather conditions, including freezing temperatures and the weight of ice or snow. Unlike other roofing materials like metal or shingles, FRP panels have a low coefficient of thermal expansion, meaning they do not contract or expand significantly with temperature changes. This characteristic minimizes the risk of cracking or breaking when exposed to freezing temperatures or the weight of accumulated ice or snow. Additionally, FRP roofing panels have a smooth surface that prevents ice or snow from sticking to them. This smooth surface allows for easy shedding of snow and ice, reducing the chances of excessive weight accumulation on the roof. However, it is important to note that while FRP panels are resistant to damage from ice or snow, they still require regular maintenance to ensure optimal performance and longevity. Overall, FRP roofing panels are a reliable choice for areas prone to ice or snow, as they offer excellent resistance to damage and provide long-lasting protection for your property.

- Q: Can FRP roofing panels be used for industrial facilities?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for industrial facilities. FRP panels are known for their high strength, durability, and resistance to corrosion, making them suitable for various industrial applications. They are lightweight yet sturdy, making installation easier and cost-effective. Additionally, FRP panels offer excellent thermal insulation and can withstand extreme weather conditions, making them a reliable choice for industrial facilities.

- Q: Are FRP roofing panels resistant to staining or discoloration?

- FRP roofing panels are known for their resistance to staining or discoloration. The exceptional gel coating applied to these panels offers superb protection against UV rays, weathering, and chemical exposure. This coating effectively safeguards the panels from fading, yellowing, or acquiring unattractive stains as time goes by. It's worth mentioning, however, that extended contact with particular chemicals or environmental elements, like strong cleaning agents or pollutants, may result in some discoloration. To guarantee the durability and visual appeal of FRP roofing panels, it is advisable to adhere to the manufacturer's maintenance guidelines and utilize mild cleaning solutions.

- Q: Can FRP roofing panels be installed on both residential and commercial canopies?

- FRP roofing panels can be easily installed on both residential and commercial canopies. With their durability, resistance to weather, and cost-effectiveness, FRP panels are an excellent choice for roofing. They are suitable for a wide range of applications, including both residential and commercial canopies. Whether it is a residential patio or a commercial awning, FRP roofing panels offer a reliable and long-lasting solution. Moreover, these panels come in various colors and designs, allowing for customization to meet the specific aesthetic requirements of both residential and commercial canopies. In summary, FRP roofing panels are highly favored for canopies in both residential and commercial settings due to their durability, versatility, and aesthetic appeal.

- Q: Are FRP roofing panels suitable for historic buildings or preservation projects?

- FRP roofing panels may not be the most suitable option for historic buildings or preservation projects. These panels are typically modern and may not blend well with the historical aesthetics of these structures. Preservation projects usually prioritize maintaining the original appearance and materials of the building, so alternative roofing options that closely resemble the original materials might be more appropriate.

Send your message to us

High-Quality FRP Roofing Panel for Corrosion-Resistant Roofing Tile and Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords