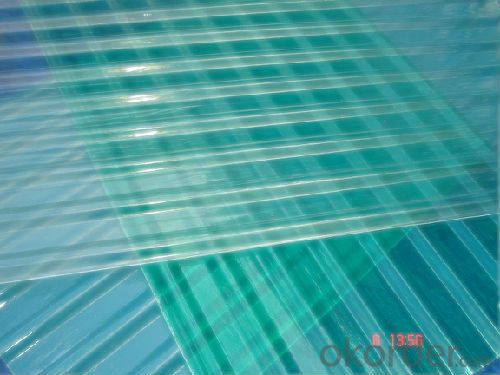

FRP Roofing Panel - Fiber Reinforcement Plastic Flat Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Fiber Reinforcement Plastic Flat Panel

The parts made via Hand Layer-up FRP(Fiberglass Reinforced Plastic) are created by applying liquid resin and fiberglass mat along with gel-coat onto an open-faced mould. The fiberglass mat will be laid into the moulds and the resin will be brushed into the fiberglass mat carefully according to the temperature and humidity situations. The semi-product after demoulded will be trimmed according to the drawings. Then the parts will be cleaned and polished to be packed.

Hand Layer-up parts are lighter and perform better on high strength-to-weight ratios. The parts made from hand layer-up FRP are with one side smooth-the gloss can be above 80. Now these parts are widely used on boat hulls, auto parts, truck and tractor covers, chemical retainers, heavy equipment panels, even rubbish cabins etc.

Applications of Fiber Reinforcement Plastic Flat Panel

1.Company building,industry building,public building,beautify the factory premises adopting the light.

2.Decorating the inside and outside of the modern business building.

3.Sound absorbtion wall for freeway,high-speed railway and sidings.

4.Subway exits,parking lots,garage tents,Bus stations,terminals,shopping arcades,large stadium and rain tents,pagodas,hallway tents.

5.Building ceiling of greenhouse

Advantage of Fiber Reinforcement Plastic Flat Panel

1. Corrosion resistance

products are resistant to the corrosion of gas and liquid of acids, alkalis, salt, and organic solvent so that they can avoid the problem of rusting steel and rotten wood.

2. Light weight and high intensity

fiberglass products are molded through the solidification of fiberglass and resin under high temperature. Its density is only one quarter of that of steel, and two-thirds of that of aluminum. But its intensity is ten times that of PVC, exceeding the aluminum products and reaching the level of common carbon steel. Due to its light weight, the products require less base support and possess the features of easy installation and low costs.

3. Inflaming Retarding

The common oxygen index of common fiberglass products is above 32 (according to GB8924). By design, the flame spreading index of the high inflaming retarding ethylene products is below 10, which meets the requirements of engineering fire resistance for safety.

4. Collision Resistance and Fatigue Resistance

fiberglass products can resist collision and keep the original shape after repeated bending so as to be used as spring.

5. Age Resistance

The normal longevity is more than 20 years. The research result shows that the intensity will still retain more than 85% after 20 years’ exposure to the atmosphere.

6.Good appearance and Easy Maintenance

The color slurry offiberglass products is mixed with resin to make the color bright and difficult to fade. No painting is needed on the surface which is clean after washing.

Main Specification of Fiber Reinforcement Plastic Flat Panel:

Item | Parameters |

Thickness | 0.8mm~4.0mm |

Width | <2.6m |

Length | 100m/roll & Pcs of special size |

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can FRP roofing panels be used for awnings or canopies?

- Yes, FRP roofing panels can be used for awnings or canopies. FRP (Fiberglass Reinforced Plastic) is a durable and lightweight material that is commonly used for roofing applications. Its strength and weather resistance make it suitable for creating awnings or canopies to provide shade and protect against the elements.

- Q: Are FRP roofing panels prone to discoloration from air pollution?

- FRP roofing panels boast a general resistance to discoloration caused by air pollution. Their composition grants them a high resistance to a range of environmental factors, including air pollution. Unlike certain other roofing materials, FRP panels are not easily affected by pollutants like dust, smoke, or chemical emissions from nearby industries or vehicles. The outer gel coat layer of FRP panels confers excellent protection against UV radiation, thereby preventing discoloration or fading resulting from prolonged exposure to sunlight. Moreover, the smooth and non-porous surface of FRP panels hinders the adherence of particles from air pollution, further minimizing the risk of discoloration. Nonetheless, it is important to note that no roofing material is entirely immune to all forms of discoloration. In areas with heavy and persistent air pollution, particularly in highly industrialized or urban regions, the appearance of FRP roofing panels may experience minor impacts over a long period of time. Regular cleaning and maintenance can help alleviate any potential discoloration or staining caused by air pollution. All in all, FRP roofing panels are widely regarded as remarkably durable and resistant to discoloration resulting from air pollution, which contributes to their popularity in various industrial, commercial, and residential applications.

- Q: Are FRP roofing panels energy-efficient?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are considered to be energy-efficient. FRP panels have excellent insulation properties, which help in reducing heat transfer and maintaining a consistent temperature inside the building. This insulation not only reduces the need for excessive heating or cooling but also helps in lowering energy consumption and costs. FRP panels also have a high light transmission capability, allowing natural light to enter the building, reducing the need for artificial lighting during the day. Additionally, FRP panels are known for their durability and longevity, which means that they require minimal maintenance and replacement, further contributing to energy efficiency. Overall, FRP roofing panels offer a sustainable and energy-efficient solution for building owners and can help in achieving energy savings and reducing environmental impact.

- Q: Can FRP roofing panels be used for car wash structures or detailing bays?

- Car wash structures or detailing bays can make use of FRP (Fiberglass Reinforced Plastic) roofing panels. These panels are highly regarded for their durability, strength, and corrosion resistance, which make them perfect for environments like car washes where they encounter water, chemicals, and frequent use. The lightweight nature of FRP panels allows for easy installation on car wash roofs or detailing bays. They can also be easily tailored to meet specific building design requirements. Moreover, FRP roofing panels possess exceptional weathering properties, guaranteeing their structural integrity and aesthetic appeal over an extended period, even when exposed to various weather conditions. In addition, FRP panels are non-conductive, meaning they do not conduct electricity. This is especially crucial in car wash structures or detailing bays where electrical equipment like lighting or power outlets are commonly employed. The non-conductive nature of FRP roofing panels reduces the risk of electrical accidents, ensuring the safety of both workers and customers. Overall, FRP roofing panels are an outstanding choice for car wash structures or detailing bays due to their durability, corrosion resistance, ease of installation, weathering properties, and non-conductive nature. Utilizing FRP panels can help create a long-lasting and safe environment for car wash operations.

- Q: Do FRP roofing panels come with warranty?

- Yes, FRP roofing panels typically come with a warranty. The specific terms and duration of the warranty may vary depending on the manufacturer and the product, so it is advisable to check with the supplier or manufacturer for more detailed information on the warranty coverage.

- Q: Can FRP roofing panels be used for schools?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for schools. FRP roofing panels are known for their durability, longevity, and resistance to various weather conditions. These panels are lightweight, making them easy to install and maintain. Additionally, FRP roofing panels are fire-retardant and can provide excellent insulation, helping to reduce energy costs for schools. The versatility of FRP roofing panels allows them to be used in a variety of school settings, including classrooms, gymnasiums, and administrative buildings. The panels are available in different colors and designs, providing aesthetic flexibility to match the school's architecture. Overall, FRP roofing panels are a practical and cost-effective option for schools, offering long-term benefits and a safe environment for students and staff.

- Q: Are FRP roofing panels resistant to lightning strikes?

- FRP roofing panels, which are also known as fiberglass reinforced plastic panels, do not possess inherent resistance against lightning strikes. Nevertheless, they are regarded as safer compared to alternative roofing materials like metal or asphalt. The rationale behind this is that FRP roofing panels are non-conductive, signifying that they do not facilitate the flow of electricity. Consequently, if lightning were to strike a structure with FRP roofing panels, the panels themselves would not attract or transmit the electrical charge of the lightning bolt. However, it is crucial to acknowledge that lightning can still present a risk to any structure, irrespective of the roofing material. Lightning seeks the path of least resistance to the ground and can travel through any conductive material, such as metal pipes or wiring, present within the building. To mitigate the risk of lightning strikes, it is advisable to install a lightning protection system. This system commonly incorporates lightning rods or air terminals placed at the highest points of the structure, along with conductive cables that run down the building and into the ground. These components aid in safely diverting the electrical charge of a lightning strike away from the structure and into the ground. In conclusion, although FRP roofing panels lack resistance against lightning strikes, they are deemed safer than certain other roofing materials due to their non-conductive properties. Nonetheless, it is imperative to implement appropriate lightning protection measures to ensure the safety of any structure, regardless of the roofing material employed.

- Q: Can FRP roofing panels be repaired if damaged?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be repaired if they are damaged. The extent of the damage will determine the repair method and whether it can be fixed or requires a replacement. Minor damages such as cracks, chips, or small holes can usually be repaired using patching compounds or sealants specifically designed for FRP materials. For larger damages or structural issues, it may be necessary to replace the damaged panels entirely. In such cases, it is recommended to consult with a professional roofing contractor who specializes in FRP roofing systems. They will be able to assess the damage and provide the best course of action for repair or replacement. Regular maintenance and inspection of FRP roofing panels can help identify potential issues early on and prevent further damage. It is important to address any damages promptly to maintain the integrity and longevity of the roofing system.

- Q: Are FRP roofing panels resistant to warping or sagging from prolonged exposure to heat?

- Yes, FRP roofing panels are highly resistant to warping or sagging even when exposed to prolonged heat. The material used in FRP panels is designed to have excellent thermal stability, ensuring minimal deformation under extreme temperatures.

- Q: Can FRP roofing panels be used for green roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for green roofs. Green roofs are designed to support the growth of plants and vegetation, and FRP roofing panels can provide a suitable base for this purpose. FRP panels are lightweight, durable, and have excellent resistance to water and weathering, making them ideal for green roof applications. Additionally, FRP panels can be designed with specialized features like drainage systems or built-in insulation, further enhancing their suitability for green roof installations. Overall, FRP roofing panels can offer a reliable and long-lasting solution for creating green roofs.

Send your message to us

FRP Roofing Panel - Fiber Reinforcement Plastic Flat Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords