FRP Honeycomb Sandwich Panels with Wooden PP Core

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard export package |

| Delivery Detail: | One week |

Specifications

honeycomb wood panel

1.LIGHT AND STRONG

2.WATER PROOF AND MOISTURE DAMPENING

3.ENERGY ABSORPTION,etc.

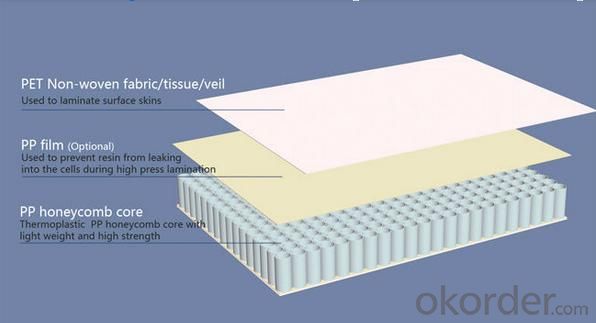

Wooden pp honeycomb sandwich panel

honeycomb wood panel : parameter

Items | Type A | Type B | Type C |

Color | White | White | White |

Cell core diameter(mm) | 8 | 10 | 12 |

Density( Kg/m3) | 80 | 75 | 70 |

Compressive Strength(MPa) | 1.66 | 1.58 | 1.47 |

Modulus of compression(MPa) | 45.7 | 41.2 | 38.9 |

Shear Strength(MPa) | 0.5 | 0.45 | 0.4 |

Effective Temperature(°C) | -40 ~ +80 | -40 ~ +80 | -40 ~ +80 |

Thermal Insulation U-value(W/m2k) | 2.2 | 2.2 | 2.3 |

honeycomb wood panel : excellences

PP honeycomb as core material, wooden skin laminated on both sides, finished panel is very light and stiffness strength enough. It's one kind of newest advertisement and decoration panel.

| Light and strong | High compressive strength. High shear strength. Low density and Light weight. |

| Green and environmentally friendly | Energy saving. 100% Recyclable. |

| Water proof and moisture dampening | With the excellent ability of water proofing, HolyCore can be well applied in the over-water buildings. Corrosion resistant. Strong resistance to chemicals, seawater eroding. Sound isolation. Efficient in reducing the damping vibration and absorbing the noises. |

honeycomb wood panel : aplications

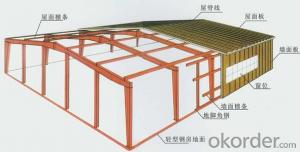

1. Construction - platform in scaffold, stadium bleachers, exhibitions and stages;

2. Ships and yachts - interior wall panels, roof, freezer, deck, etc;

3. Automobiles interior decorations, van body walls and so on;

4. Logistic Various kinds of boxes and containers.

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- The system after spraying the rigid foam polyurethane insulation layer in the wall to form a continuous seamless overall, winter can avoid the heat bridge, greatly reduce the indoor heat loss; summer can greatly reduce the sun due to the external walls of the heat conduction, and then So that heating, air conditioning, energy consumption, energy saving effect is obvious, can reduce energy consumption, protect the theme structure, to extend the life of the building

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Foam benzene board capacity of not less than 18kg, other indicators in line with national regulations

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. These panels provide excellent insulation, durability, and aesthetic appeal, making them a practical choice for creating a modern and visually appealing showroom. Additionally, sandwich panels can be customized to meet specific design requirements and offer ease of installation, making them a suitable option for automotive showrooms.

- Q: This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- Color steel sandwich panels have the effect of thermal insulation, these two types of panels can be used for houses and workshops, are able to waterproof

- Q: What is the weight per unit area of 100 thick rock wool sandwich panels?

- The development of safe electricity technical measures and electrical fire prevention measures. ⒋ construction site temporary electricity safety technology files: ⑴ temporary electricity construction organization design and modify the construction organization design all the information. ⑵ technology to the end of information. ⑶ temporary electricity inspection inspection table. ⑷ grounding resistance measurement records. regular inspection (complex) look-up table (site monthly, the company once a quarter). ⑹ earthen worship of the cut of the irrigation pipe tax japonica maintenance work records. ⒌ installation, repair or removal of temporary electricity projects, must be completed by the electrician, electrical grade should be consistent with the degree of engineering and technical complexity to adapt. Second, the electrician: ⒈ electricians must go through professional and safety technical training, by the (city) labor department examination issued a certificate of operation, the prospective independent operation. ⒉ electrician should grasp the basic knowledge of electricity safety and all equipment performance. ⒊ before the job as required to wear personal protective equipment. slightly....

- Q: 02J611-4 aluminum alloy color steel stainless steel sandwich panel door Atlas who made a thank you

- Generally 6 meters outside the scaffolding,This is not clear!

- Q: Color steel sandwich board on the price of how much?

- Solid wood particle board moisture-proof effect than the wood sandwich board moisture-proof effect is better than the solid wood particle board and wood sandwich board difference . solid wood particle board, is made of wood or other lignocellulosic material, after the application of adhesive Heat and pressure under the action of synthetic wood-based panel. Solid wood particle board as a new, high-grade environmentally friendly substrate. Solid wood particle plate inside the cross-scattered structure of the granular. So the nail force is good, you can nail round nails, screws. These machinability is significantly better than MDF. . solid wood particle density is higher, the board of wood fiber particles larger, more to retain the nature of natural wood, in the use of solid wood particles on the board content is generally less than 5%, better environmental protection. Solid wood grain plate warp deformation small, stable size, good, high strength, good stiffness, hanging heavy clothing is not easy to bend. At present in the European furniture market, the use of wood-based panel is also solid wood particle board. . wood sandwich panels inside and outside the two sides for the glass plate, sandwich layer waterproof plywood, the German vacuum technology from high pressure compound. Sandwich panel surface smooth, dirt can be easily removed, the entire panel colorful, with excellent light-blocking. . fiberglass plate surface has a layer of excellent performance gel coat, the atmosphere, water and the general concentration of acid, alkali, salt and other media has a good chemical stability; surface finish, excellent light retention, no discoloration, corrosion resistance , Anti-sun, anti-aging. The main application areas: dry cargo compartment, large span structure roof, wall, purification plant, high profile portfolio housing, container rooms and so on.

- Q: Color steel sandwich panels and synthetic resin tile which is more market

- Online shopping bar, do not go to the supermarkets to buy online shopping, then remember that can not be less than 250 points below the price of a sub-goods

- Q: Can the foam sandwich be used as a cleaning plate?

- According to the "construction of fasteners steel scaffolding safety technical specifications" JGJ

- Q: Steel structure workshop roof load is the number of specific Please thank you

- Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs The substrate of the color steel plate is a cold-rolled substrate, a hot-dip galvanizing substrate, and an electro-galvanized substrate Coating types can be divided into polyester, silicon modified polyester, polyvinylidene fluoride and plastic sol The surface condition of the color steel plate can be divided into coated board, embossed plate and printing plate The color steel plate is widely used in the construction of household appliances and transportation industry The construction industry is mainly used for steel industry, airport, warehouse and freezing industry Commercial buildings of the roof walls and doors, etc, civil buildings using less color plate

Send your message to us

FRP Honeycomb Sandwich Panels with Wooden PP Core

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords