Fiberglass Foam Sandwich Panels - EPS Sandwich Roof Panel for Hot Sell and Good Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Sandwich Panel

Sandwich panel is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials. Sandwich panel is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, Sandwich panel has features temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

2.Main Features of the Sandwich Panel

1) Our EPS sandwich panel has the following characteristics:light dead weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

2) The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3) It is easy to install and can be used many times over.

4) Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

5) Apart from EPS sandwich panels, Wiskind also offers rock wool sandwich panels, glass wool sandwich panels, PU sandwich panels, honeycomb sandwich panels.

6) These products have all passed ISO9001 and ISO14001 certification. Due to their high quality and low price, they are well received by our customers in Russia, Australia, Angola, Congo, and Korea, etc.

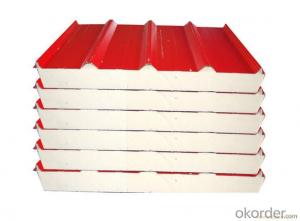

3. Sandwich Panel Images

4. Sandwich Panel l Specification

Effective width Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm

Length According to customer's request

Materials Polystyrene foam board(EPS), Color steel sheet

Structure Upper and lower layer: Color steel sheet

Middle: polystyrene foam board

Thickness Color steel sheet: 0.3-0.6mm

Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm

The polystyrene density 8-20kg/m3

Conventional color RAL standard

Character Light in weight, heat insulation, water resistant, green and environmental

Use various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

5.Advantages of Sandwich Panels

1) Heat and sound insulation: The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2) A degree inflaming retarding: This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3) Environment protection: By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4) Super-low heat conductivity: The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

5) Easily and quick installation

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

2) A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

3) How to guarantee the quality of the products?

4) We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5) How long can we receive the product after purchase?

6) In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I have a temporary pavement, the roof for the Caigang sandwich panels, north and west for the pure glass wall, south of four large area of plastic windows, east brick wall, an area of 150 square feet, 5 meters high. Summer sun good time when the house hot, temperature 35 degrees or more. Ask how the decoration, so that the temperature can come down, the cheaper the better the cost. (The ceiling has no effect, the role of large or small, there is no other way) Thank you, high score waiting. More

- (Including: Fluorocarbon metal paint, fluorocarbon solid paint, real stone paint, imitation stone paint, granite, relief supporting, imitation brick texture, texture matching, etc) and insulation materials series (including: XPS , EPS, PUR, phenolic board, rock wool board, ultra-thin insulation board), for the old and new concrete, steel structure, real brick wall, hollow brick wall, brick wall wall, combined with the company to install patent, Construction of the wall installation TDD insulation decorative board is not only suitable for the new building exterior insulation and decoration, but also for the old building of low-carbon energy-saving decorative transformation, and not affected by regional differences

- Q: What is the difference between the board and the core board? The The

- 024 (thermal conductivity of the lower insulation effect The better) Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation The cost is still lower than the infusion process

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- The wall is relatively smooth, the external wall insulation per square meter with the mortar 4-foot often end of the shop to the whole shop 6 kg foot; wall is the wall, more mortar, a square need 7-9 kg

- Q: Similar to the color steel tile, floor board, the roof of the push is how much ah

- (Polyurethane waterproof coating, asphalt, etc.); small gap, you can directly hit the silicone sealant; the same time, you can use the silicone sealant, Above all have to ensure that color steel plate fixed firmly, or if loose will damage the water

- Q: What is the quota of the demolition of the color steel plate?

- Answer: safety production laws and regulations, including safety in production (BE) A

- Q: What are the different types and uses of clean color steel plates?

- Playing glass glue, with a little better quality.

- Q: Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. They are lightweight, strong, and provide excellent insulation properties. Additionally, sandwich panels can be easily installed and offer a wide range of design options, making them a practical and efficient choice for train station construction.

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- Buy the quality of a little bit of what the material is no problem, although the price is more expensive, but the first safety is important

- Q: Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Color steel room is a color steel composite panels (also known as Caigang sandwich panels) for the wall to light steel structure for the skeleton built. The color galvanized steel coating to maintain a period of 10-15 years, so the theoretical life can be more than 10-15 years, but also with the environment, the use of materials, quality and maintenance methods.

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- The price of the foam board depends on its density, the higher the density, the more expensive the price

Send your message to us

Fiberglass Foam Sandwich Panels - EPS Sandwich Roof Panel for Hot Sell and Good Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords