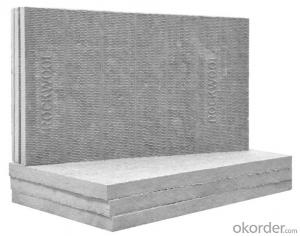

Rockwool Core Facade Sandwich Panels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock Wool Sandwich Panel

1. Thickness of steel: 0.3mm-0.8mm

2. Density of Rock wool: 100kg/m3

3. Thick of rock wool: 50-200

Rock Wool Sandwich Panel

Product details:

1. Thickness of steel: 0.3mm-0.8mm

2. Density of Rock wool: 100±5kg/m3

3. Thickness of rock wool: 50, 75,100,120,150,200mm

Advantage:

1. Waterproof,

2. Sound proof,

3. Earthquake proof,

4. Heat preservation,

5. Environmental.

Features:

1) Energy-saving, lightweight, and environmental protection

2) Polyurethane foam has good heat-insulation effect

3) Energy-saving effects of the building is greatly improved

4) Raw materials do not include harmful substances

5) Environmental protection, it is highly recommended by the government

8) Waterproof and damp resistant

9) With fireproof feature

10) Good appearance

Product Introduction:

The two sides of Rock wool sandwich panel is made of zinc and aluminum steel plated, core material is rock wool. The steels are pressed through the automated continuous molding machine and bind together with rock wool with high-strength adhesive bonding.

Usage:

Widely used as fireproof, soundproof, or heat preservation materials for walls, roofs and internal partitions of industrial and civil buildings, especially of projects in high fireproof requirements.

4. FAQ

A, Could be changed the size of the panel?

Yes, we design the size according to your requirement.

B, What is the color of the panel?

All the colors in "RAUL"

- Q: What is the difference between the board and the core board? The The

- General I-beam cross-section height of not less than 160mm

- Q: I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- The metal hose is an important connecting member in engineering technology

- Q: Similar to the color steel tile, floor board, the roof of the push is how much ah

- General wallpaper glue is sticky, you can consider using white latex to try.

- Q: Sandwich panels and Malacca ecological board what is the difference

- Man can pipe the plastic tube can be directly within the tube to detect the actual deformation value

- Q: Color steel room life in general how many years

- The price with the upper and lower color plate thickness, polystyrene bulk density, there are regional differences are related. Specifically you can call the local color steel factory.

- Q: Can sandwich panels be used for noise barriers?

- Sandwich panels are indeed a viable option for noise barriers. Typically, these panels consist of two outer layers made from rigid materials like metal or wood, with an insulating layer in between. This insulating layer functions to absorb and dampen sound waves, making sandwich panels an effective solution for noise barriers. The insulating material used in sandwich panels can vary, with options such as mineral wool or polyurethane foam, both of which possess excellent sound absorption properties. These materials are specifically designed to trap and dissipate sound energy, effectively preventing it from passing through the barrier and reducing noise levels on the opposite side. When it comes to noise barriers, sandwich panels can be customized to meet specific requirements for noise reduction. By adjusting the thickness and density of the insulating layer, the desired level of sound insulation can be achieved. Additionally, the outer layers can be designed to either reflect or absorb sound, depending on the desired acoustic performance and aesthetic preferences. There are several advantages to using sandwich panels for noise barrier applications. Firstly, they are lightweight, making them easy to install and transport. Furthermore, they possess a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Lastly, sandwich panels can be engineered to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. To summarize, sandwich panels are an ideal choice for noise barriers due to their sound absorption properties, customization options, and durability. They effectively reduce noise levels, creating a quieter environment for various applications, including highways, factories, residential areas, and commercial buildings.

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- The inner panel can be installed with conventional technology, pay attention to the edge, the installation of corners, as well as their installation with the wallboard order, part of the first to install

- Q: What are the different types and uses of clean color steel plates?

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed time when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the amount of rain on the big leak, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask questions.

- Q: 02J611-4 aluminum alloy color steel stainless steel sandwich panel door Atlas who made a thank you

- You can find the relevant property management patiently about the exchange, from the professional point of view, it is recommended that you choose the East Rainbow waterproof products and standardized construction team, the East Rainbow is the best quality waterproof listed enterprises RPUF-371 spray Dust polyurethane waterproof and thermal insulation integration system "Rainbow" spray foam polyurethane foam waterproof insulation integrated system is a rigid foam polyurethane foam waterproof insulation integrated material and the protection of the surface layer composition

- Q: What kind of manual sandwich panels can be done? What is the difference between a manual sandwich panel and a mechanism sandwich panel? More

- Pipe pressure deformation, pressure relief pipe is not restored, the clamp inside the leather pad is not restored, there may be water seepage

Send your message to us

Rockwool Core Facade Sandwich Panels

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords