Sandwich Panels Composites GI GL CR Corrugated Steel Sheet Color Steel Laminboard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy),with pallet |

| Delivery Detail: | 20-25 days after receiving the deposit |

Specifications

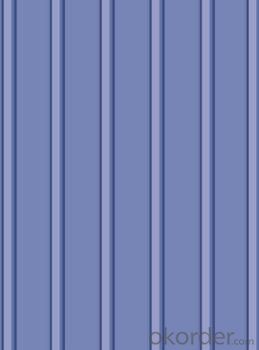

PPGI, PPGL , GI , GL, CR and Corrugated steel sheet

thickness : 0.12mm to 1.2mm,

width :600mm to 1500mm

zinc coat:30-275g

We can offer PPGI and GI in thickness available from 0.12mm to 1.2mm, width available from 600mm to 1500mm

Basic information

1: Size: 0.15-1.2mm*600-1250mm

2: Paint: Top side: 15-25um, Back side: 5-9um, or according to customer’s order.

3: Base material: Hot dipped galvanized steel coil, GL

4: Zinc coating: 30-275g.

5: Coil weight: 3-6tons

6: Coil ID: 508mm

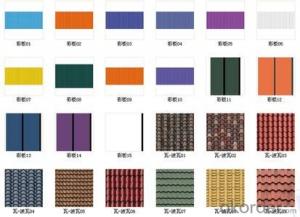

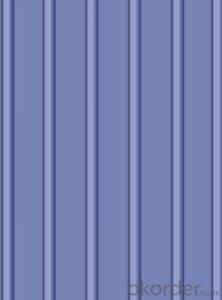

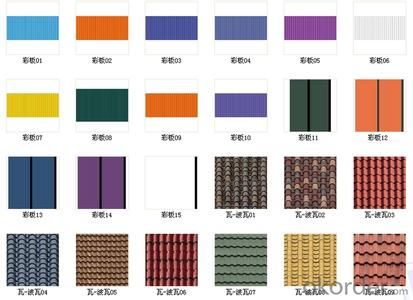

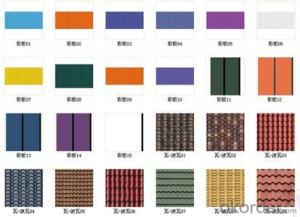

7: Color: Any color.

8: Standard: ASTM, GB, JIS

9:Grade: CGCC,CGCH,SGCC, DX51D and ASTM

10:Surface Treatments: skin passed, chromated, oiled and antifinger

11: Approved Certificate: SGS / ISO9001 / BV

12: Package Method: Vertical/Horizontal, full wrapped with anti-moist paper inside, iron sheet (sea worthy)

13: Payments terms: T/T ,L/C,etc.

Brief Introductionof product

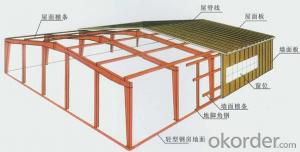

1. Color Coated steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for Color Coated Steel Coil consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of Color Coated Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Color Coated Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Color Coated Steel Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Mechanical Properties

1. Mechanical properties of base metals

Grade | Tensile Test | ||

Yield Strength MPa | Tensile Strength MPa | Elongation A80mm % ≥ | |

SGLCC | 140-350 | 270-500 | 22 |

SGLCD | 140-300 | 270-420 | 26 |

SGLCDD | 140-260 | 270-380 | 30 |

2. Common performance of front coating

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <3ΔE

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- On the basis of absorbing and studying the employee 's crisis consciousness and improving the desire, they summarize the ten ideas of self - improvement

- Q: General color steel foam sandwich panels. How much a square is flat

- Big core board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending strength than

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

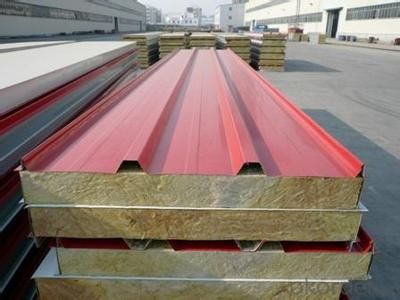

- Polyurethane sandwich panel insulation good insulation, good overall stiffness, high bearing capacity, suitable for clean room, warehouse, commercial buildings, indoor and outdoor gymnasium, cold storage, indoor partitions and so on. Rock wool sandwich panels fire superior performance, sound-absorbing effect is significant, thermal insulation slightly inferior to polyurethane, but the price is cheaper than polyurethane, suitable for steel structure plant, simple activities of the roof or wall, air clean room ceiling and partition The

- Q: Can sandwich panels be used for noise barriers?

- Sandwich panels are indeed a viable option for noise barriers. Typically, these panels consist of two outer layers made from rigid materials like metal or wood, with an insulating layer in between. This insulating layer functions to absorb and dampen sound waves, making sandwich panels an effective solution for noise barriers. The insulating material used in sandwich panels can vary, with options such as mineral wool or polyurethane foam, both of which possess excellent sound absorption properties. These materials are specifically designed to trap and dissipate sound energy, effectively preventing it from passing through the barrier and reducing noise levels on the opposite side. When it comes to noise barriers, sandwich panels can be customized to meet specific requirements for noise reduction. By adjusting the thickness and density of the insulating layer, the desired level of sound insulation can be achieved. Additionally, the outer layers can be designed to either reflect or absorb sound, depending on the desired acoustic performance and aesthetic preferences. There are several advantages to using sandwich panels for noise barrier applications. Firstly, they are lightweight, making them easy to install and transport. Furthermore, they possess a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Lastly, sandwich panels can be engineered to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. To summarize, sandwich panels are an ideal choice for noise barriers due to their sound absorption properties, customization options, and durability. They effectively reduce noise levels, creating a quieter environment for various applications, including highways, factories, residential areas, and commercial buildings.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient

- Q: Are sandwich panels suitable for train stations?

- Train stations can benefit from the use of sandwich panels, a construction material consisting of two outer layers and an insulating core. These panels offer excellent thermal insulation, fire resistance, and soundproofing properties, making them an ideal choice for train station applications. The insulation provided by sandwich panels helps to regulate the temperature inside the station, creating a comfortable environment for passengers and staff regardless of external weather conditions. This can result in reduced energy consumption and lower heating or cooling costs. Fire resistance is crucial in train stations, where the risk of fire is a major concern. Sandwich panels are highly fire-resistant, which can help contain and slow down the spread of fire. This provides valuable time for evacuation and firefighting efforts. Sandwich panels also offer excellent soundproofing capabilities, reducing noise transmission in train stations. This creates a more peaceful and comfortable atmosphere for passengers and staff. Furthermore, sandwich panels are lightweight, easy to install, and cost-effective. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are a suitable choice for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, benefiting both passengers and staff.

- Q: Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- Excavation works of earth and rock.The construction unit should prepare a special program

- Q: 02J611-4 aluminum alloy color steel stainless steel sandwich panel door Atlas who made a thank you

- Generally 6 meters outside the scaffolding,This is not clear!

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- The price of the foam board depends on its density, the higher the density, the more expensive the price

- Q: What kind of manual sandwich panels can be done? What is the difference between a manual sandwich panel and a mechanism sandwich panel? More

- Never use the insulation board as a noise board, sound into the cavity can be converted into heat, closed cavity sound waves can not I am the most expensive, because the problem is good, but the quality of your use is not known

Send your message to us

Sandwich Panels Composites GI GL CR Corrugated Steel Sheet Color Steel Laminboard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords