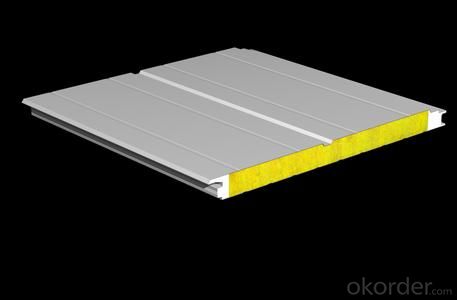

PUF Insulated EPS/XPS MgO Sandwich Panels, Structural Insulated Panel (SIP)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard wooden pallets or in bulk |

| Delivery Detail: | 15-25 days after confirm order |

Specifications

Mgo eps Sandwich Panels

1.No VOC's or Offgasing

2.Energy Effieient

3.Easy Construction

4.Movable

EPS/XPS MGO Sandwich Panels,Structural Insulated Panel(SIP)

Specification:

1. Core Material: EPS, XPS, PU; Surface Material: Magnesium Oxide Board ,calcium silicate board, fiber cement board

2. Thickness: 35~250mm, option is available

3. Max. Width: 1220mm, recommend 1150mm or 1100mm

4. Length: 2400mm, 2700mm, 3000mm, 3600mm, option is available

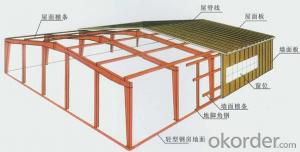

5. Application: Wall & ceiling, partition wall,

6. Widely applied in common steel structure, prefabricated house and etc, which comes from industrial plants, commercial buildings, hospitals and so on.

Characteristic:

1. Good performance of heat insulation and warm keeping

2. Superior fire rating with Class A MGO board and fire retardant EPS/XPS

3. Environment friendly with high quality glue and upon customers' decisions optional

4. Convenient installation, cutting is easy, size and thickness is custom-made, multiple joint methods optional

Usage:

1) Temporary offices, dormitories, warehouse and workshop in construction sites and in municipal works and residential resettlements

2) Temporary commercial housings in the cities, such as exhibition halls, shopping centers, offices and other housings for exhibition and sports

3) Holiday inns or container house, leisure villas and holiday homes in tourist spots.

4) Temporary houses used in large-scale fieldwork, such as exploiting energy sources and making tunnels, warehouse

5)Temporary houses in military field and temporary housings in earthquake, fire, hurricane and flood disaster-affected areas

6)large area suspended ceiling, separation of steel structure workshop, suspended ceiling, wall body and air purification room.

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. Sandwich panels are made up of two outer layers or skins with a lightweight core material in between, providing excellent strength and insulation properties. These panels are versatile and can be used for various applications, including building facades, partitions, and interior walls. In automotive showrooms, sandwich panels can be used for constructing walls, ceilings, and even floors. They offer several benefits that make them ideal for this environment. Firstly, sandwich panels provide excellent insulation, which helps maintain a comfortable temperature inside the showroom, regardless of the weather outside. This is crucial for creating a pleasant environment for both customers and staff. Additionally, sandwich panels are lightweight and easy to install, allowing for quick and efficient construction. This is beneficial for automotive showrooms, as they often have tight deadlines and need to be operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, allowing for flexibility in creating unique and attractive showroom layouts. Sandwich panels also offer good noise reduction properties, ensuring a quieter environment within the showroom. This is important for providing a comfortable atmosphere for customers and allowing them to focus on the vehicles on display. Furthermore, sandwich panels are durable and require minimal maintenance. They are resistant to corrosion, moisture, and fire, ensuring a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for branding and aesthetic preferences to be incorporated into the showroom design. Overall, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They provide a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: General color steel foam sandwich panels. How much a square is flat

- but generally do not choose the best

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- scaffolding must be set vertical and horizontal sweep longitudinal rod should be used at right angle fastener fixed at the bottom of the pipe at 200mm at the vertical pole should be fixed with fast nuts By the vertical pole pole

- Q: Own balcony capped, with the kind of sandwich panels better, EPS sandwich panels or rock wool sandwich panels, or other kind of sandwich panels?

- The greater the density. Strength is higher. But the thermal conductivity is the lower However, I do squeeze nail fan teeth both hands and pay only try to dig a thin plate of this line a little bit of time it is recommended that you still choose the high density of the thermal conductivity will be low, not much lower. Just some of the sales of the plate to the low density that means a good thing only.

- Q: How does the wall rock wool sandwich panel be installed?

- the basis for the preparation (the relevant laws and regulations, standards, construction drawings, computing software, etc

- Q: Can the foam sandwich be used as a cleaning plate?

- According to the "construction of fasteners steel scaffolding safety technical specifications" JGJ

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- Wood insulation effect can be, the smaller the density the better insulation, asbestos or glass wool will be better, but the price of your Kazakhstan

- Q: Steel structure workshop roof load is the number of specific Please thank you

- Contents The first chapter of the construction site safety technical information management of the main contents and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technical information Four sections of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (the second file box) third (The third file box) Section IV of the safety of the construction organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (sixth file Box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident (the tenth file box ) Section XI Safety signs (eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (the twelfth file box) thirteenth Machinery and equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union labor protection information

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- The price of the foam board depends on its density, the higher the density, the more expensive the price

- Q: What kind of manual sandwich panels can be done? What is the difference between a manual sandwich panel and a mechanism sandwich panel? More

- the bottom of each pole should be set at the bottom or pad

Send your message to us

PUF Insulated EPS/XPS MgO Sandwich Panels, Structural Insulated Panel (SIP)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords