Tata Sandwich Panels - Fiberglass FRP Reinforced PP Honeycomb Panel & FRP Sandwich Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | standard export pellet,with protective corner guard and film on the four sides |

| Delivery Detail: | 7DAYS |

Specifications

fiberglass honeycomb panel:

light weight&high strength

anti-impact insulation

chemical resistant

excellent thermal

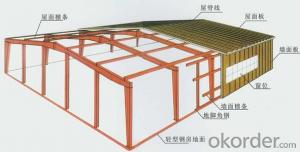

FRP PP Honeycomb Sandwich Panel

Thickness: | 8mm-120mm,according to your application |

Width: | up to 2600mm,standard size 1.22m |

Length: | 2440mm standard, can be customer specific |

Colours: | RAL-, NCS scale or customer-specific shades |

uv/weathering | Excellent protection |

Bonding preparation: | both side smooth or sanded; bonding with appropriate adhesives possible |

Typical Features:

1. Light-weight&high-intensity 2. fire resistant & insulation

3.anti-impact&scratch 4. Corrosion resistant

5.easy to clean & install 6. Anti-mildew, mould, moisture, resistant

7. Resilient to weathering and hail 8. Excellent thermal characteristics

Application:

1. Billboard/ Boat building

2. Indoor Partition /Product Showcase/ Advertising identification panels

3. Prefabricated houses/ dog kennels

4. Caravan industry/ Vehicle construction/container house

5. Building industry/ Airline industry

FRP Sandwich Panel can be widely used for

Truck body&RV Body:light and high strength; Easy processing and assembly,UV resistant..

Boat(Deck and Inside Wall):light and energy conservation,Good shock absorption,waterproof and resistant corrosion,sound insulation..

Moving Building Material(Wall Panel,Floor panel):Easy assembly and reusable,Good shock absorption,waterproof and resistant corrosion,sound insulation..

Foot Treadle&Platforms(Anti-slip with frp anti-slip sheet):Light weight And High strength...

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- Or the whole building with the framework of the masonry, or steel structure with masonry Steel structure with the concrete in the economy is very optimistic Just the structure is at least 30% higher than the concrete structure, because at present our steel is relatively small

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- On the basis of absorbing and studying the employee 's crisis consciousness and improving the desire, they summarize the ten ideas of self - improvement

- Q: Sandwich panels and Malacca ecological board what is the difference

- You can use the shear wall, and then hollow insulation can reduce the noise, but the cost of high

- Q: General color steel foam sandwich panels. How much a square is flat

- Big core board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending strength than

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- scaffolding must be set vertical and horizontal sweep longitudinal rod should be used at right angle fastener fixed at the bottom of the pipe at 200mm at the vertical pole should be fixed with fast nuts By the vertical pole pole

- Q: Can sandwich panels be used for noise barriers?

- Yes, sandwich panels can be used for noise barriers. Sandwich panels are typically made of two outer layers of rigid materials, such as metal or wood, with a layer of insulating material in between. This insulating layer helps to absorb and dampen sound waves, making sandwich panels an effective choice for noise barriers. The insulating material in sandwich panels can be made of various materials, such as mineral wool or polyurethane foam, which have excellent sound absorption properties. These materials are designed to trap and dissipate sound energy, preventing it from passing through the barrier and reducing the noise levels on the other side. Sandwich panels for noise barriers can be customized to meet specific noise reduction requirements. Different thicknesses and densities of the insulating layer can be used to achieve the desired level of sound insulation. Additionally, the outer layers can be designed to be reflective or absorptive, depending on the desired acoustic performance and aesthetic preferences. Sandwich panels offer several advantages for noise barrier applications. They are lightweight, making them easy to install and transport. They also have a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Furthermore, sandwich panels can be designed to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. In conclusion, sandwich panels are a suitable choice for noise barriers due to their sound absorption properties, customization options, and durability. They can effectively reduce noise levels and provide a quieter environment for various applications, such as highways, factories, residential areas, and commercial buildings.

- Q: Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. They are lightweight, strong, and provide excellent insulation properties. Additionally, sandwich panels can be easily installed and offer a wide range of design options, making them a practical and efficient choice for train station construction.

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

- Q: Steel structure workshop roof load is the number of specific Please thank you

- General color steel foam sandwich panels. Price in the 45 - 60 yuan / M ? or so.

- Q: The stove is dedicated to the plastic used for plastic paper

- It is best not to sleep so, first bubble is airtight! The skin is very bad, long-term will also affect the health

Send your message to us

Tata Sandwich Panels - Fiberglass FRP Reinforced PP Honeycomb Panel & FRP Sandwich Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords