Fiberglass FRP Reinforced PP Honeycomb Panel & FRP Sandwich Panel - Sandwich Panels Nz

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | standard export pellet,with protective corner guard and film on the four sides |

| Delivery Detail: | 7DAYS |

Specifications

fiberglass honeycomb panel:

light weight&high strength

anti-impact insulation

chemical resistant

excellent thermal

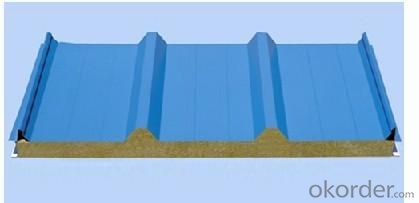

FRP PP Honeycomb Sandwich Panel

Thickness: | 8mm-120mm,according to your application |

Width: | up to 2600mm,standard size 1.22m |

Length: | 2440mm standard, can be customer specific |

Colours: | RAL-, NCS scale or customer-specific shades |

uv/weathering | Excellent protection |

Bonding preparation: | both side smooth or sanded; bonding with appropriate adhesives possible |

Typical Features:

1. Light-weight&high-intensity 2. fire resistant & insulation

3.anti-impact&scratch 4. Corrosion resistant

5.easy to clean & install 6. Anti-mildew, mould, moisture, resistant

7. Resilient to weathering and hail 8. Excellent thermal characteristics

Application:

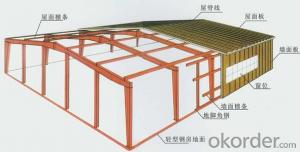

1. Billboard/ Boat building

2. Indoor Partition /Product Showcase/ Advertising identification panels

3. Prefabricated houses/ dog kennels

4. Caravan industry/ Vehicle construction/container house

5. Building industry/ Airline industry

FRP Sandwich Panel can be widely used for

Truck body&RV Body:light and high strength; Easy processing and assembly,UV resistant.

Boat(Deck and Inside Wall):light and energy conservation,Good shock absorption,waterproof and resistant corrosion,sound insulation...

Moving Building Material(Wall Panel,Floor panel):Easy assembly and reusable,Good shock absorption,waterproof and resistant corrosion,sound insulation

Foot Treadle&Platforms(Anti-slip with frp anti-slip sheet):Light weight And High strength.

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Foam benzene board capacity of not less than 18kg, other indicators in line with national regulations

- Q: I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- Easy to install, to prevent future loss is not tied

- Q: Similar to the color steel tile, floor board, the roof of the push is how much ah

- 5 cm, 10 cm, 15 cm and 25 cm The general material 5 cm price between 45 to 75 yuan; 75 cm price of 55 to 90 yuan range; 10 cm price of 70 to 100 yuan, Caigang Caigang purification plate thickness can also Custom So we must first understand their choice of materials and thickness, different scenes of the plate is not the same choice

- Q: Color steel sandwich panels and color steel plate What is the difference

- Excuse me, where are you in? Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The There is that you can use .7 inside the expansion screw, to the hardware store to find can match. You can also use welding, then a long screw, is also very simple.

- Q: Own balcony capped, with the kind of sandwich panels better, EPS sandwich panels or rock wool sandwich panels, or other kind of sandwich panels?

- Safety Management 2. Civilized construction. Fastener steel scaffold 4. Door steel scaffold 5. Bowl button steel pipe scaffolding 6. Socket type plate fastener type steel scaffolding 7. Full house scaffolding 8. Suspended scaffolding 9. Attachment lift scaffolding 10. High operating basket 11. Foundation Pit Engineering. Template holder 13. High work 14. Construction electricity 15. Material hoist 16. Construction lift 17. Tower crane 18. Lifting hoisting. Construction equipment

- Q: Can sandwich panels be used for noise barriers?

- Yes, sandwich panels can be used for noise barriers. Sandwich panels are often made of two outer layers of rigid materials with a core of insulating material, which helps in reducing noise transmission. These panels can effectively absorb and block noise, making them suitable for constructing noise barriers in various settings such as highways, construction sites, or industrial areas.

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- Wall insulation is an important part of the work of home insulation, divided into external wall insulation and internal wall insulation two, the amount of internal wall insulation works much smaller than the external wall insulation, Xiaobian today to share the advantages and disadvantages of various interior wall insulation materials The Polystyrene foam board polystyrene foam board is one of the three common wall insulation materials

- Q: What are the different types and uses of clean color steel plates?

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed time when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the amount of rain on the big leak, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask questions.

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- Expandable polystyrene foam board (referred to as polystyrene board, the EPS board). Polystyrene Biscuit Powder Kuba Kawakun Fung Mo foam products are processed intermediate products, with less investment, fast turnover, low energy consumption, occupation of production personnel less, the production of high profit products. At the same time the number of devices less simple operation, strong production flexibility, product quality has a reliable guarantee, and thus the project construction risk is small. EPS board is made of polystyrene (EPS) beads made by foam molding. Polystyrene is invented in the 1950s, polystyrene foam products is a new type of advanced insulation, noise insulation materials. It is light in quality, non-toxic and tasteless, without any pollution. Use is very wide, mainly used for refrigerators, trains, ships, limousines, mobile homes, housing insulation insulation. Instrumentation, porcelain, glass products, home appliances and other packaging. In the construction industry it is an alternative to moisture-proof powder, perlite, asbestos and other insulation materials, is a very wide range of new products, so far there is no one product to replace the market prospects are very broad.

Send your message to us

Fiberglass FRP Reinforced PP Honeycomb Panel & FRP Sandwich Panel - Sandwich Panels Nz

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords