POLYURETHANE FOAM sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Detailed Product Description

1. Heat and sound insulation. Temperature suitable for PU ranges from -200 centigrade to

150 centigrade.

2. Good chemical resistance, waterproof, anti-corrosion, insect-free etc.

3. Advanced Tech: Automatic rolling machines make the whole process of manufacture

effective.

4. Energy conservation, environmental protection, economical, heat insulting,

good structure,

easy-doing construction

5. Light weight enough to reduce building expense.

6. Time can be saved on a building project due to the simple installation

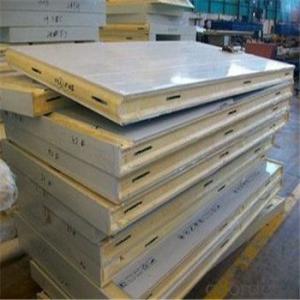

PU Sandwich panel (Polyurethane sandwiched panel )is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials.

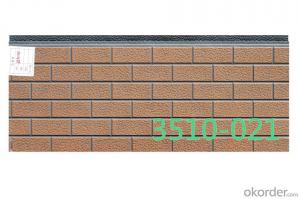

It is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, which features

temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

PU insulation sandwich panel

PU board adopts quality raw material from BASF which guarantees the qualtiy of foamed boards.

The board is formed in one time by pressure injection machine with color steel sheet or stainless steel sheet on both sides.

The polyurethane inside is spread evenly which guarantees a high efficiency in thermal insulation and lowers cold

consumption, thus, the customers operation cost is

pu panel sandwich

PU Sandwich Panel(Width 1000mm,100mm)

1, the quality of light weight per square meter of less than 24kg, can reduce the cost of the structure.

2, quick installation of light weight, splicing, installation and can be arbitrarily cutting characteristics, determine its

installation is simple, can improve efficiency, save the time.

3, fire, Caigang composite plate core surface materials and insulation materials for the non-fuel or burning material, can meet the requirements for fire protection.

4, refractory, with a special coating color steel plate and the new 10-15 years, after every ten years spraying anti-corrosion coating, sheet life over 35 years

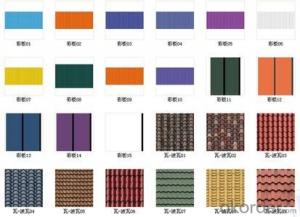

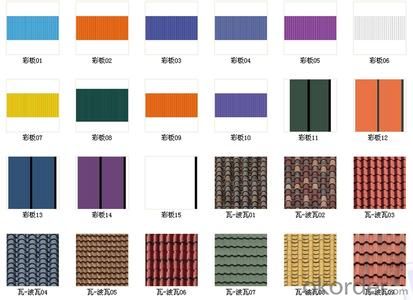

5, beautiful, pressure plate clear lines of dozens of kinds of colors, can be matched with any style of the building takes

6, insulation insulation material commonly used are: rock wool glass fiber, cotton, polystyrene, polyurethane, low thermal

conductivity, good thermal insulation effect.

7, environmental noise prevention, composite board insulation strength up to 40-50 dB, is very effective sound insulation materials.

8, strong plasticity sheet steel can be cut, enough to meet the special design needs.

9, high strength with high strength steel plate as a substrate, the tensile strength of 5600 ( kg / cm2 ), plus on the most advanced design and roll forming, and has excellent structural properties

Applications:

1) sandwich panel used in large industrial plants, warehouses, supermarkets, hospitals, stadiums, cold storage, activities

room, buildings plus layer, clean workshop and heat insulation fire place.

2) sandwich plate appearance, bright color, good overall effect, it sets the bearing, thermal insulation, fireproof, waterproof

in one, and no two decoration, is a widely used, especially in the construction site of the temporary facilities such as office,

warehouse, walls, but also embodies the modern construction site civilization construction,

3) in the fast installation and put into use, the assembly and disassembly, material turnover multiplexing index, have

obvious advantages, greatly reducing the construction site temporary facilities, will be indispensable new lightweight

construction materials

This kind of pu sandwich panel has characters as follows:

Material:

1. steel strip:up/bottom 0.3- 1.2mm colourcoated steel panel/zinc plate,hot galvanized plate/stainless steel plate

2. core material: density of PU:30-80kg/m3

Specification:

1.T he applicable width of interface;950mm,1150mm

2. thichness:40mm-250mm

3. no length limit.

product perfomance: light and durable,easy to install, large usage

Fire-resistance rating:B

Usage: This kind of sandwich panel can be used in steel structure workshop,easy building and air clean room as walls

,ceilings. Especially for cold storage

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Extrusion board is different from the foam board, bulk density can not be arbitrarily changed, the technical units to do relatively light But not less than 30kg / cubic meter is generally 35kg / m3 or so manufacturers and manufacturers different

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. Sandwich panels are made up of two outer layers or skins with a lightweight core material in between, providing excellent strength and insulation properties. These panels are versatile and can be used for various applications, including building facades, partitions, and interior walls. In automotive showrooms, sandwich panels can be used for constructing walls, ceilings, and even floors. They offer several benefits that make them ideal for this environment. Firstly, sandwich panels provide excellent insulation, which helps maintain a comfortable temperature inside the showroom, regardless of the weather outside. This is crucial for creating a pleasant environment for both customers and staff. Additionally, sandwich panels are lightweight and easy to install, allowing for quick and efficient construction. This is beneficial for automotive showrooms, as they often have tight deadlines and need to be operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, allowing for flexibility in creating unique and attractive showroom layouts. Sandwich panels also offer good noise reduction properties, ensuring a quieter environment within the showroom. This is important for providing a comfortable atmosphere for customers and allowing them to focus on the vehicles on display. Furthermore, sandwich panels are durable and require minimal maintenance. They are resistant to corrosion, moisture, and fire, ensuring a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for branding and aesthetic preferences to be incorporated into the showroom design. Overall, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They provide a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- The wall is relatively smooth, the external wall insulation per square meter with the mortar 4-foot often end of the shop to the whole shop 6 kg foot; wall is the wall, more mortar, a square need 7-9 kg

- Q: Color steel sandwich panels and color steel plate What is the difference

- Color steel sandwich panels are divided into rock wool sandwich panels, foam sandwich panels, rock wool color steel sandwich panels

- Q: Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- Polyurethane sandwich panel insulation good insulation, good overall stiffness, high bearing capacity, suitable for clean room, warehouse, commercial buildings, indoor and outdoor gymnasium, cold storage, indoor partitions and so on. Rock wool sandwich panels fire superior performance, sound-absorbing effect is significant, thermal insulation slightly inferior to polyurethane, but the price is cheaper than polyurethane, suitable for steel structure plant, simple activities of the roof or wall, air clean room ceiling and partition The

- Q: Are sandwich panels suitable for train stations?

- Train stations can benefit from the use of sandwich panels, a construction material consisting of two outer layers and an insulating core. These panels offer excellent thermal insulation, fire resistance, and soundproofing properties, making them an ideal choice for train station applications. The insulation provided by sandwich panels helps to regulate the temperature inside the station, creating a comfortable environment for passengers and staff regardless of external weather conditions. This can result in reduced energy consumption and lower heating or cooling costs. Fire resistance is crucial in train stations, where the risk of fire is a major concern. Sandwich panels are highly fire-resistant, which can help contain and slow down the spread of fire. This provides valuable time for evacuation and firefighting efforts. Sandwich panels also offer excellent soundproofing capabilities, reducing noise transmission in train stations. This creates a more peaceful and comfortable atmosphere for passengers and staff. Furthermore, sandwich panels are lightweight, easy to install, and cost-effective. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are a suitable choice for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, benefiting both passengers and staff.

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- First of all, the tempered glass can no longer be drilled high and the ancient antecedant for the short hole, will certainly be broken, and do not make the edge of the local force, but also fragile (so use a few bumps to block it The method is not good) should be tempered glass as a whole embedded in a slot, you can in the low side of the welding of a corner, the length of the glass and the same edge, play a block of the role, in addition, usually the tempered glass is not easy to be deformed Damage, but can not make it too much force

- Q: Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Q: Consult the requirements of the flame retardant 0 standard from which the standard standard, and then ask the next level 0 flame retardant standard self-extinguishing time is how much. More

- Clamp material, and pressure ah, a little bit of deformation of the clamp will lead to the next time the use of water leakage; some clamp is sealed with rubber ring, pressure, the rubber ring is not fully restored, will lead to Leakage of water; some cases in the pressure, the pipeline to the development of the process of training, but also lead to tight hoop tightly

- Q: Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- That depends on the savvy! Way more than difficult!

Send your message to us

POLYURETHANE FOAM sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords