Arcelormittal Durable Anti-Poisoning Fiberglass XPS Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Protective film on each panel, panels into standard seaworthy pallet, foam protection, special corner protective material for Fiberglass XPS Sandwich Panel |

| Delivery Detail: | upon deposit at stock or 7days after deposit for products |

Specifications

Sandwich Panel 1.Light Weight

2.Impact Resistance

3.Thermal Insulation

4.Corrosion Resistant

5.Anti-UV

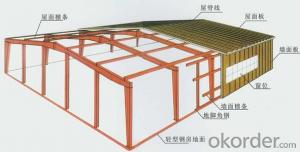

Durable Anti-poisoning Fiberglass XPS Sandwich Panel

Description:

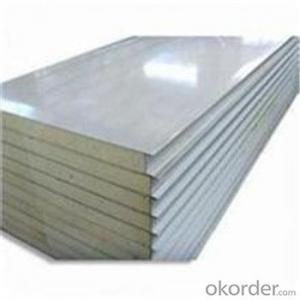

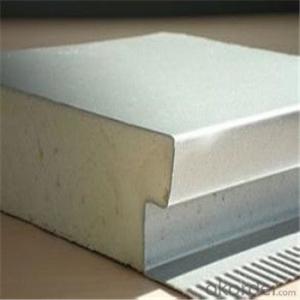

Fiberglass Reinforced Plastic (FRP) sheet as surface panel at both sides, Polystyrene (XPS also called Extrusion board) as core. They are compounded from high pressure and vacuum, guaranteeing the strength and stability.

The manufacturing process involves the bonding of two outer faces or high gloss FRP flat sheet under pressure to an inner core of insulation material being High density EPS/XPS/PU foam. Using Daison FRP produces sandwich panels with excellent physical attributes including flexible strength, high rigidity, column strength and high impact resistance.

Specification:

Effective width | Wall panel: 950mm 1150mm 1200mm; Roof panel: 950mm 980mm |

Length | According to customer's request |

Materials | Extruded Polystyrene Foam (XPS), fiberglass reinforced plastic (FRP) |

Structure | Upper and lower layer: FRP sheet |

Middle: XPS/EPS/PU foam board | |

Thickness | FRP sheet: 0.8-6mm |

Density of XPS | 30-65kg/m3 |

Color | Ral-scale or customer specific |

Features | Light in weight, heat insulation, water resistant, green and environmental |

Application | Hatchery & incubation equipment, compartments and external walls of building and truck body, cleaning workshops,etc. |

- Q: Will the Yanmian sandwich panels do external wall insulation wall can paste tiles? Do A-class insulation of the external wall insulation materials can be posted what kind of it?

- What are the best companies (including imported products) in China?

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- I have a veteran to sell, because I just bought a new Taiwan, the price of ..

- Q: This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- There is no harm have to brush your teeth ah ~ Do not you do not brush it? You are so powerful

- Q: What are the different types and uses of clean color steel plates?

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed time when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the amount of rain on the big leak, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask!

- Q: 02J611-4 aluminum alloy color steel stainless steel sandwich panel door Atlas who made a thank you

- You can find the relevant property management patiently about the exchange, from the professional point of view, it is recommended that you choose the East Rainbow waterproof products and standardized construction team, the East Rainbow is the best quality waterproof listed enterprises RPUF-371 spray Dust polyurethane waterproof and thermal insulation integration system "Rainbow" spray foam polyurethane foam waterproof insulation integrated system is a rigid foam polyurethane foam waterproof insulation integrated material and the protection of the surface layer composition

- Q: Can the foam sandwich be used as a cleaning plate?

- According to the "construction of fasteners steel scaffolding safety technical specifications" JGJ

- Q: Are sandwich panels suitable for retail outlets?

- Yes, sandwich panels are suitable for retail outlets. They offer excellent insulation, durability, and aesthetic appeal, making them an ideal choice for creating a comfortable and visually appealing environment for customers. Additionally, sandwich panels can be easily customized to meet specific design requirements and can be installed quickly, minimizing downtime during construction or renovation projects.

- Q: Consult the requirements of the flame retardant 0 standard from which the standard standard, and then ask the next level 0 flame retardant standard self-extinguishing time is how much. More

- Steel pipe is a steel pipe bowl buckle is the connection point like a bowl button is the connection point is a disk above a lot of hole pin is not a national standard thing is not recommended to use

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- When the top of the ventilation tube can not be extended out of the roof, the following ventilation can be used: ①, set the side wall ventilation tube ②, by setting the confluence of the ventilation pipe after the extension of the side wall to extend above the roof ③, set up self-circulation ventilation pipeline system , the following circumstances should be set up ventilation riser: ①, when the drainage pipe to take the sanitary equipment drainage design flow than in Table 449 only set the top of the drainage pipe drainage pipe maximum design drainage capacity ②, the building standards require a high multi-storey residential and public buildings, 10-storey and 10-storey high-rise building life drainage riser , the following drainage pipe should be set up annular ventilation pipe: ①, connecting four and more than four sanitary ware and the length of more than 12m of the drainage pipe ②, connecting 6 and 6 or more toilet toilet cross pipe ③, do not exceed the above provisions, but the nature of the building is important, the use of high requirements or set the device when the ventilation tube , the health, quiet requirements of the building, the living drainage pipe should be set to ventilator tube , the drainage pipe at all levels of the building shall be provided with an annular ventilation pipe, and shall be provided with a main ventilation riser or a secondary ventilation riser for the connection of the layers , ventilation riser shall not accept the equipment of sewage, waste water and rain; not connected with the duct and flue

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- Expandable polystyrene foam board (referred to as polystyrene board, the EPS board). Polystyrene Biscuit Powder Kuba Kawakun Fung Mo foam products are processed intermediate products, with less investment, fast turnover, low energy consumption, occupation of production personnel less, the production of high profit products. At the same time the number of devices less simple operation, strong production flexibility, product quality has a reliable guarantee, and thus the project construction risk is small. EPS board is made of polystyrene (EPS) beads made by foam molding. Polystyrene is invented in the 1950s, polystyrene foam products is a new type of advanced insulation, noise insulation materials. It is light in quality, non-toxic and tasteless, without any pollution. Use is very wide, mainly used for refrigerators, trains, ships, limousines, mobile homes, housing insulation insulation. Instrumentation, porcelain, glass products, home appliances and other packaging. In the construction industry it is an alternative to moisture-proof powder, perlite, asbestos and other insulation materials, is a very wide range of new products, so far there is no one product to replace the market prospects are very broad.

Send your message to us

Arcelormittal Durable Anti-Poisoning Fiberglass XPS Sandwich Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords