Frequency Inverter Single-phase 220V class 75KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

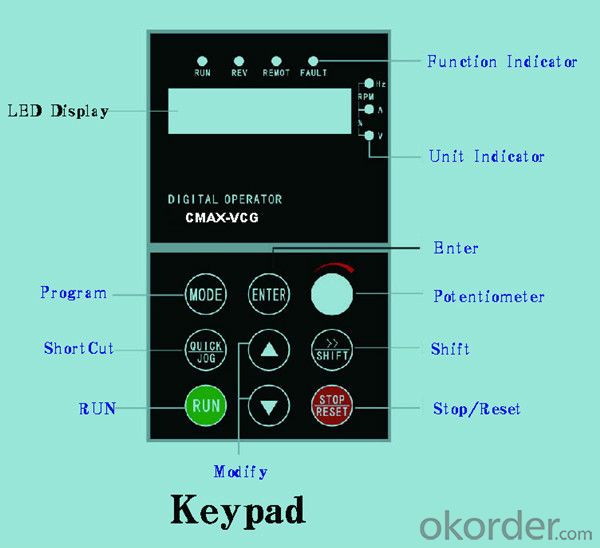

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: What's the frequency converter for? What does it look like?

- AC motor stepless speed regulation can save energy in some occasionsThe appearance of the basic manufacturers are one of the same

- Q: When the inverter is running at full 50HZ, the output voltage decreases and the output current becomes smaller. What is the reason?

- However, when the frequency is raised, the current will decrease if the load is not large, especially when the motor is idle. The magnitude of the current is determined by the load. If you can add some load, you will see the current rise. Speaking of principles, can be understood as the motor is a big inductance, when the power frequency increases, the motor impedance Z will become larger, the impedance is large, the voltage is constant, the flow of the current will naturally be small,

- Q: Knowledge, principle and operation method of frequency converter.

- The three major parts of the working principle of frequency converter:This is how the inverter works, but how does it work? Mainly composed of three components. (1) convert the power frequency power to the rectifier of the DC power: it transforms the power frequency power into the DC power supply. A reversible converter can also be constructed using two sets of transistor converters, which can be regenerated for their reversible power direction. (2) absorption in the converter and inverter voltage generated by the pulsating "flat wave circuit" in the rectifier DC voltage is rectified, ripple voltage with power frequency 6 times, in addition the pulsating current generated by the inverter to the DC voltage fluctuation. (3) the DC power conversion for AC power rectifier with "inverter": instead, the inverter is DC power converter for AC power required frequency, to the time the 6 switch off, you can get 3 phase AC output.

- Q: What are the key points of frequency converter maintenance?

- Frequency converter daily patrolDo the inverter daily inspection and inspection work, inspection contents mainly include: ambient temperature, humidity is required, ventilation windows is good; the inverter air inlet and outlet is blocked by dust or too much dust; inverter operation parameter is normal, there is no alarm; cabinet fan the operation is normal; if there is abnormal sound or vibration transducer; capacitor whether overheat.

- Q: Not to say that the inverter speed is mainly down frequency, how can I see the frequency rise to 60HZ, so that the three-phase motor is not more than the rated speed?

- Frequency rising problem of frequency converter;Voltage matching; the rated voltage of the converter is in line with the rated voltage of the load.Current matching; ordinary centrifugal pump, the rated current of the converter is in line with the rated current of the motor. For special loads, such as deep water pumps, it is necessary to refer to the motor performance parameters and determine the current and overload capacity of the inverter with maximum current.Torque matching; this situation may occur when a constant torque load or a deceleration device.

- Q: What is a frequency converter?

- The frequency converter is the electric energy control device that transforms the power frequency power to another frequency by the on-off function of the power semiconductor device. The frequency converter is mainly composed of rectifier (AC DC converter), filter, inverter (DC AC converter), brake unit, drive unit, detection unit, micro processing unit and so on.

- Q: 5.5KW frequency converter with 4.5KW deep water pump, pressure regulator by conveying signal to frequency converter start normal, the pressure to reduce the frequency converter after the start, to about 30Hz in order to maintain the pressure about shocks, 30 seconds inverter over-current alarm. Can it be the fault of the frequency converter? How should I check it?

- overloadOverload faults include frequency overload and motor overload. It may be caused by the acceleration time is too short, the network voltage is too low and the load is too heavy. Generally by extending the acceleration time, extending the braking time, check the power grid voltage. Overload, the selected motor and inverter can not drag the load, or it may be caused by poor mechanical lubrication. Such as the former, you must replace the high-power motor and inverter; if the latter is to overhaul the production machinery.

- Q: Can a power converter be used in a motor with small power? Will it burn the motor?

- If it is overloaded with constant torque, the vector control or DTC, then not power motor inverter below 1/4, otherwise the inverter to motor "modeling" is not accurate, easy to control and protection of the disorder is not perfect.

- Q: Frequency converter OC alarm, what's the matter?

- The frequency at which the OC fault occurs in all faults of the inverter may be the highest and the most frequent. In the process of starting the alarm, in the process of stopping the alarm, alarm in operation, so that power on the alert, and even with other fault codes or currentIndirectly tell you that there is a OC fault in this inverter!

- Q: Which brand of converter is better?

- Supporting the use of Sinopec group, double coin group and other national key projects, the quality of product quality and good customer service service won the praise of users!

Send your message to us

Frequency Inverter Single-phase 220V class 75KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords