Frequency Inverter Single-phase 380V class 275KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

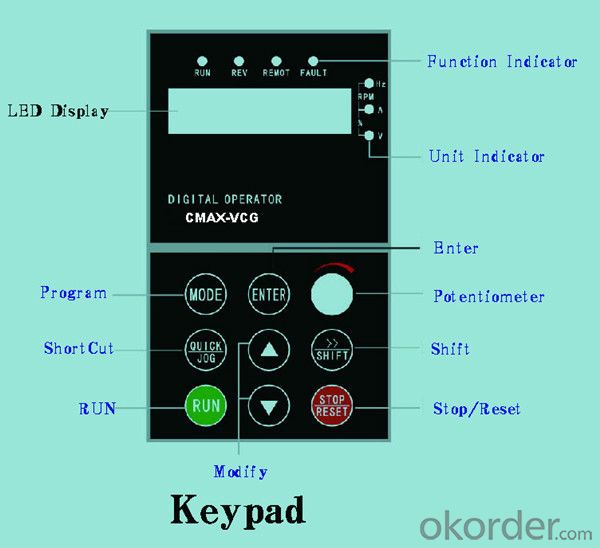

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: The frequency converter is in use suddenly the speed reduces, then the debugging is out of control, how to do?

- Overvoltage prevention measures: due to over-voltage causes are different, so the countermeasures are not the same. For overvoltage in parking, if there is no special requirement for parking time or position, it can be solved by using extended frequency converter, deceleration time or free parking. The so-called free parking, that is, the frequency converter will switch off the main switch, so that the motor free sliding stop. If the parking time or parking position have certain requirements, then the DC brake (DC brake) function can be used

- Q: What is the difference between frequency converter and servo driver?

- The difference between servomotor and frequency conversion motor:Servo system is a closed-loop control system, the inverter usually works in open-loop control, so in terms of speed and accuracy, and can not be compared to the servo drive.The frequency conversion is only one part of the servo, and the servo controls the closed loop precisely on the basis of frequency conversion so as to achieve better results.

- Q: What does Ro1c mean on a converter?

- RO1C is the common terminal and the RO1A is normally closed, and the RO1B is normally open. The set of contacts is the output signal that is ready to run. That is, the self-test of the converter is completed and the output signal of the relay can be operated.

- Q: What are the precautions for frequency converter wiring installation?

- First understand the instructions, do not take the control line wrong, power line into the wire outlet is connected, you can debug it

- Q: What is the frequency converter through function?

- Inverter through function refers to:The converter can temporary loss of power in the power grid when using mechanical transducer can keep running, as long as the rotation of the motor and the inverter to provide energy, although the speed will decrease, but the converter will run normally (power mode), and if the grid connected inverter in state grid voltage recovery after the inverter can be immediately put into normal electric state.

- Q: How can I control the frequency converter with a computer?

- The commonly used PLC and DCS control system in industrial area are applicable to the conditions of inverter interface control module, can realize the closed-loop converter convenient automatic control in the control system, widely used in large and medium. The control device for some smallexperimental device and embedded processor in inverter control, generally also need to deal with the keyboard input, display, data acquisition and other work such as process control, this control is more suitable for single-chip control system as the core, and uses PLC and operation panel, it can achieve the function but the cost is too high. Should not be used.

- Q: What are the benefits of installing economizer in industrial enterprises?

- According to the frequency above 3 disadvantages, we developed and produced for Saver series under different conditions, based on frequency conversion technology, according to the field of electricity, increase control cabinet, electric / power conversion system, load detection and control system, input and output filter, DC reactor device etc.. The economizer has 4 advantages over the inverter:

- Q: I do mining equipment, recently I used ABB frequency converter to put into our equipment, but the problem of interference really gives me a headache! We have two pieces of equipment of SIEMENS S7-200 PLC, and is used in point to point protocol communication with each other, when the converter work PLC communication interference! There are monitoring equipment, converter work, there are a large number of snowflakes on the screen, simply do not see! Not even an internal phone! I've done well in grounding, but I still can't do it! Is there any master who can teach me a trick?

- You can try using the following methods:Solution of interference caused by circuit coupling:The PLC and monitoring equipment are powered by isolated transformers.

- Q: Frequency converter OC alarm, what's the matter?

- Description of the OC fault in the inverter manual, following several explanations: the load side short-circuit current greater than OC, run jump failure is two times; the output of the inverter module circuit; current transducer; overload; acceleration and deceleration time is too shortEtc.. Some models do not use OC to mark such faults. They are explained by load side short circuit, frequency converter overload, serious ground fault and so on. This is of course the alias of OC fault.

- Q: How to choose frequency converter?

- 1. the power of the inverter is selected according to the load power. How many power motors should be chosen for a multi power motor?. Size one is ok.2. frequency converter model, different uses, choose different frequency converter. For example, there are general frequency converter, fan, water pump dedicated inverter, a machine tool spindle dedicated inverter. Wait。

Send your message to us

Frequency Inverter Single-phase 380V class 275KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords