AC Driver China Best Selling VFD Frequency Drive 3 phase 380V 11kw

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

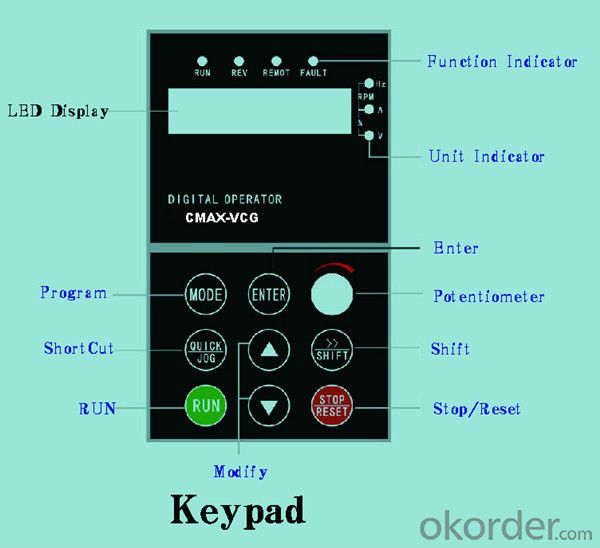

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

- Q: Schneider 303 4KW frequency converter F 013 trouble shooting method

- According to the ATV303 user manual,The F013 is a motor overload fault and is triggered by excessive motor current.Suggest:1. monitor the running condition of the converter with the panel (whether the actual running current exceeds the limit)2. check the motor thermal protection settings and motor load (such as motor drive chain bearings, reducer, etc.).

- Q: 1, the frequency converter to the motor cable should be shielded cable? 2, whether there are specifications?

- Do not use shielded cables have several conditions: the first is from the inverter to motor wear long steel pipe laying cable. Second is the frequency converter to the motor cable line routing (cable bridge, cable ditch), there is no analog signal cable or other weak signal cable. Otherwise, from the debug runtime, if the inverter cable cable line motor and analog signal very close, even if the analog signal shielded cable control cable when the motor running is still very obvious interference of analog signals, especially large power motor.

- Q: What is frequency conversion? What is the function of frequency converter?

- Theoretically, the inverter can be used in all mechanical equipment with electric motor, the motor starts, 5-6 times higher than the rated current, will not only affect the motor service life and consume more power. In the design of the system in the motor selection will leave some margin, the speed of the motor is fixed the same, but in actual use, sometimes running at low or high speed, so the frequency transformation is very necessary. Transducer can realize soft starting and compensating power factor of motor

- Q: PT100 temperature patrol instrument, when the converter is not open, the measurement is normal. Once opened, it shows completely disorder, and sometimes there are puzzling characters. How can I solve this problem? Please enlighten master!

- In the complex electromagnetic environment, AnyWay advocates the idea of digital front end, that is, in the vicinity of being measured, the signal will be digitized, and then the uploaded information will be uploaded to the host computer through digital communication. Digital transmission is much better than analog transmission in anti-interference ability. If the electromagnetic interference is very large, the transmission line can be changed into optical fiber transmission. In this way, the transmission link can completely avoid interference.

- Q: How can I control the frequency converter with a computer?

- Variable frequency speed control has been applied in the industrial field as the main means of AC motor speed control is very extensive, it has a wide speed range, steady speed and high precision fast dynamic response for a wide range of technical performance and reliable operation, has gradually replaced the DC motor speed control system. There are three main control modes of inverter: 1. through inverter panel operation, that is through the operation panel to change the output frequency and other operating parameters; 2. in the frequency converter analog input 0 ~ 10V or 4 ~ 20mA signal, by changing the size of input analog control of inverter output frequency converter; 3. through communication port (for RS485 control). The first method is generally used for manual adjustment and parameter setting on the spot, and the latter two are mostly used for automatic adjustment and remote control.

- Q: What does "frequency" in household appliances mean?

- The new inverter refrigerator not only the reduction of power consumption, realize mute, and the use of high-speed operation can achieve substantial rapid freezing; in the washing machine, used frequency variable speed control, improve washing performance, washing machine popular in addition to saving energy and silent, still ensure soft clothing washing and other aspects of the introduction of control new content;

- Q: Is the voltage low? The younger brother is bored to death, no problem with the wire drawing machine, the full load will jump off. Display frequency converter overload and acceleration operation overcurrent. Help me please.

- There are only three reasons for the POFF fault: (1) the DC bus voltage detected by the machine is seriously low. (2) lack of phase signal. (3) the voltage level parameter of 220V machine is wrong. [method] use the shift key on the keyboard or the mask to switch the display content to the display bus voltage status.

- Q: The frequency converter works with sharp noises. What's the process of converting electrical energy into mechanical energy?. The mechanism of sound making. Thank you

- There is no doubt that the sound we hear is the sound produced by mechanical vibrations. When the inverter is idle, just as upstairs, it says only a slight noise from the fan, but there is a squeal when loaded

- Q: I would like to ask, the inverter in use in the grid is very high?

- In the process of using inverter, grid voltage fluctuation requirements is not high, the general phase is to allow + 20% fluctuations, three-phase is allowed 15% fluctuations, so most of the grid voltage can be satisfied, unless it is in the countryside, or more remote areas, the voltage change will exceed the allowable value. In addition, the frequency converter on the power grid harmonics also have requirements, if the harmonic content of more than 20%, will lead to frequency converter misoperation, false alarm, more serious circumstances, will lead to inverter out of control, or damage. However, most of the current harmonics will not happen, unless a large number of individual factories use frequency converters, servo, intermediate frequency furnace, welding machine and other equipment.

- Q: What do you mean by the capacity of the inverter and the capacity of the motor?

- That's not the case at all"Capacity" and "power" are essentially different. Usually we say that a large transformer capacity is how much KVA, but not to say how much KW, because the two are not the same thing

Send your message to us

AC Driver China Best Selling VFD Frequency Drive 3 phase 380V 11kw

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords