China VFD Frequency Inverter 3 phase input 3 phase output 220V /380V

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

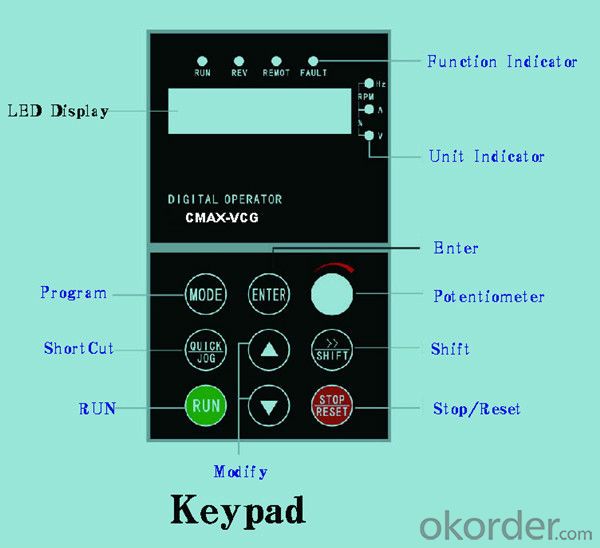

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: That is, some parameters of the inverter, such as torque, current, frequency, etc., are displayed on the Kingview software interface, but not through the PLC. The idea that the MODBUS protocol between SIEMENS and 200PLC has never been successful before, so that's the idea of the ABB. If it can be achieved,Is it necessary to write the script program on the Kingview, and what problems should I pay attention to when using the MODBUS protocol in Kingview software?The problem is a little bit more, I hope the experts teach me this rookie! Thank you

- 1, requires two communications. The PLC and the Kingview use a communication port individually, and the PLC and the inverter use a communication port alone. 2, Kingview and PLC communication time, Kingview is the master station, PLC is from the station; and PLC and converter communication, PLC is the master station, frequency converter is from the station. 3, frequency converter control, do not use communication, use digital point output and analog output. 4, PLC and inverter as the slave station using Kingview configuration; Wang put the data to the PLC, let PLC run the program, go to the PLC of the configuration parameters of the inverter control read out, and then sent directly from the Kingview converter.

- Q: How does the frequency converter fit the brake unit and the brake resistor?!

- Calculate the motor energy, as to choose how much resistance, another factor is the braking time. If a short time braking, requires relatively large resistance, on the other hand, can choose small resistance. This depends on the mechanical requirements.

- Q: Which country invented the inverter?

- The frequency converter is not developed by a certain individual, it is the research result of a large number of scientific research workers.The background of inverter technology is the wide demand of AC motor stepless speed regulation. The traditional DC speed regulation technology is limited because of its large size and high failure rate.

- Q: How does the PLC process the inverter output signal?

- 1. The analog signals of the converter (such as the 4~20mA signal) are received in the analog input module of the PLC (for example, the EM235 module)2, the input signal processing (32000 digital quantity into 50HZ frequency signal)3. Compare the resulting frequency signals with their own internal settings

- Q: What are the differences between the two quadrant and the four quadrant of the inverter?

- For a motor alone, the so-called four quadrant refers to its operating mechanical characteristics curve, on the mathematical axis of the four quadrants can run. The first quadrant is in the positive electric state, the second quadrant feedback braking state, the third quadrant reversing electric state, and the fourth quadrant reverse braking state. A frequency converter that makes the motor work in the four quadrant is called the four quadrant converter.

- Q: How to deal with the fault Yaskawa inverter GF

- Inverter display "GF" fault information for ground fault (i.e. the output current exceeds the rated current of the inverter 50%), a power module is reported for G5 damage, may also be a driving circuit, running the report "GF" (the external load is a good case), G5 is PC929 damage. With current detection circuit,

- Q: How can I control the frequency converter with a computer?

- The use of single-chip to control the inverter can choose the last two kinds of methods, the use of communication control, the utility model has the advantages of full control function, suitable for inverter through the level conversion circuit form of communication (RS484/RS232/CAN), you can communicate with the inverter hardware is simple, the number of connections between the two less convenient connection. The disadvantage is that we need to understand the communication protocol of frequency converter to control programming, and the software design is complicated. The inverter communication interface and communication protocol of different brands are different, there is no uniform standard, only for a converter for development, narrowing the selection range of the frequency converter varieties, the applicability is limited. As for the analog input control, can support almost all of the inverter is, although the function is relatively simple, but the main function can realize speed, can meet the use requirements of the majority of occasions, universal.

- Q: What is the difference between SIEMENS inverter and built-in filter?

- The filter is used for electromagnetic interference protection. Not only for the protection of electrical equipment, but also for the use of environmental protection. Inverter application environment is very extensive. Industry, light industry, commerce, civil, etc.. So the level of electromagnetic protection is also different.By the way。 If you disconnect the converter. See a coil on a board. That's the built-in filter. If you don't have it, you don't have that coil.

- Q: What are the contents of frequency converter maintenance?

- Operators must be familiar with the basic principles of inverter, functional features, with basic knowledge of electrical operations. Before checking and maintaining the frequency converter, the total power supply of the equipment must be cut off, and the inverter Chang lamp will be completely extinguished.

- Q: What do you mean by the capacity of the inverter and the capacity of the motor?

- That's not the case at all"Capacity" and "power" are essentially different. Usually we say that a large transformer capacity is how much KVA, but not to say how much KW, because the two are not the same thing

Send your message to us

China VFD Frequency Inverter 3 phase input 3 phase output 220V /380V

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords