Frequency Inverter Single-phase 220V class 0.75KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

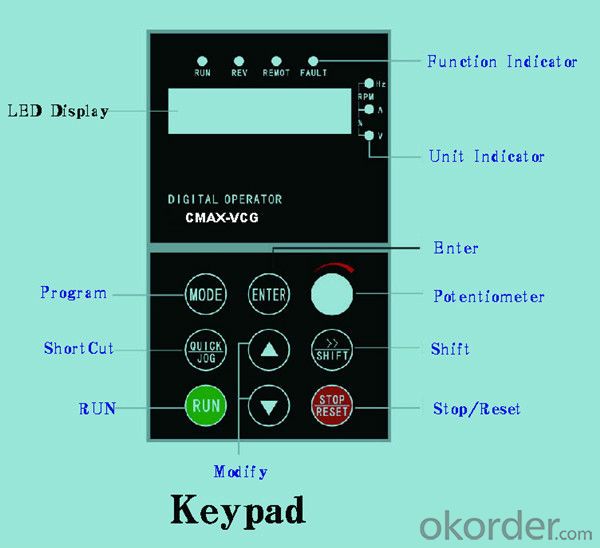

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: At the base block Yaskawa inverter is what reason?

- For example: when you put the inverter to stop, there will be a signal to the inverter, then the converter will base the blockade, cut off the output, the motor will no longer work; when you need a converter work, there will be a signal to the inverter, inverter will cancel the locks on the base, and the normal work,This function is only equivalent to one protection.

- Q: High-voltage converterGeneral inverterPump frequency converterEngineering frequency converterCould you tell me some frequency converter according to the class?

- Specific answer to your question: 1, high voltage inverter: This is based on the input voltage level terms. Generally speaking, 10KV is more than 6KV voltage high voltage frequency converter, 1140V, 3300V in general is medium (some people also called it the high voltage level of 380V, 660V), 480V, commonly called the low-voltage inverter; 2, pump inverter: This is according to the type of application in terms of. Fan pump inverter mainly refers to the frequency converter used to drag fans, pump load, the main feature is light load, simple application.

- Q: What are the key points of frequency converter maintenance?

- 1., regular cleaningAlways check the frequency converter regularly and keep the environment clean and dry. It is strictly prohibited to place sundries near the frequency converter, and someone should regularly clean the frequency converter, blow it out, keep the cleanliness of the converter and the ventilation of the air duct.2. treatment methodsIf it is found within the inverter or radiator plate dust and debris falling into, should promptly use compressed air to blow off. Clean air filter, cooling air duct and interior dust. When it is found that the conductor and insulator have corrosion, it should be promptly cleaned with alcohol.For continuously running inverters, the running state can be visually checked from outside. Periodically inspect the converter and check if there is any abnormality when the converter is running. The following tests should normally be carried out:

- Q: Not to say that the inverter speed is mainly down frequency, how can I see the frequency rise to 60HZ, so that the three-phase motor is not more than the rated speed?

- When the high speed motor is driven by a transducer, the higher the higher harmonic is, the higher the output current value is due to the small reactance of the high speed motor. Therefore, the type selection of frequency converter used in high speed motor is slightly larger than the selection of ordinary motor.And if you want a long cable converter operation, this time to take measures to curb the influence of long cable on the coupling capacitor, to avoid the shortage of inverter output, so in this case, the frequency converter to enlarge the capacity of a file or install the output reactor in the inverter output.And for some special applications, such as high temperature, high altitude, at this time will cause the inverter derating, frequency converter to enlarge the capacity of a block.

- Q: What is the function of a frequency converter on an electric motor?

- Through the frequency converter, the motor can be adjusted speed, so as to obtain the speed required by itself, and also can reduce the motor running current and save energy and reduce consumption.

- Q: Ask, what is the ratio of frequency converter?

- Connect the air switch, the power supply, check the wiring is correct, close the air switch, turn on the frequency converter, and the digital tube shows 0.Turn off the power, the power indicator light is extinguished, then connect the motor, on-off switch, tone potentiometer, trimmer potentiometer, inching button, frequency meter (0 ~ 10V voltage meter), three sets of inverter and motor proportion of joint operation, the inverter and the motor grounding terminal reliable grounding, and carefully check.

- Q: What does Ro1c mean on a converter?

- Relay output converter dry contact signal, RO1C is the common end and RO1A is closed, RO1B is normally open, this set of contacts is prepared to run the factory setting output signal, power on self-test is completed can run the relay output signal. It can be modified to the output point of the signal such as fault and operation in the twenty-fourth set of parameters.

- Q: What is the frequency converter through function?

- The default power loss time is 5S.Using DSU's high-power inverters, you need to set the time delay in DSU software to activate this function.The power down function is unique across some converter functions. In the power plant, semiconductor, petrochemical and other industries has been widely used to solve the power problem recurring and electricity, the massive economic losses caused momentary loss of power equipment downtime caused by continuous production. To protect the user to the greatest extent.

- Q: Heating inverter commissioning steps

- The no-load connection test of the frequency converter will connect the grounding terminal of the frequency converter to the ground 1. 2 the power input terminal of the frequency converter is connected to the power supply through the leakage protection switch. 3 check the frequency converter display window factory display is normal, if not correct, should reset, or request exchange. 4 familiar with the operation key of frequency converter. The inverter has run in general (RUN) and stop (STOP), programming (PROG), P (DATAPENTER), the data confirm the increased (UP, 3), reduce (DOWN, 6) and other key definitions of different inverter operation keys are basically the same. In addition, some inverters also monitor (MONITORPDISPLAY), reset (RESET), inch movement (JOG), shift (SHIFT) and other functional keys.

- Q: I would like to ask, the inverter in use in the grid is very high?

- In the process of using inverter, grid voltage fluctuation requirements is not high, the general phase is to allow + 20% fluctuations, three-phase is allowed 15% fluctuations, so most of the grid voltage can be satisfied, unless it is in the countryside, or more remote areas, the voltage change will exceed the allowable value. In addition, the frequency converter on the power grid harmonics also have requirements, if the harmonic content of more than 20%, will lead to frequency converter misoperation, false alarm, more serious circumstances, will lead to inverter out of control, or damage. However, most of the current harmonics will not happen, unless a large number of individual factories use frequency converters, servo, intermediate frequency furnace, welding machine and other equipment.

Send your message to us

Frequency Inverter Single-phase 220V class 0.75KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords