China best selling VFD Frequency Drive 3 phase 380V 55KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

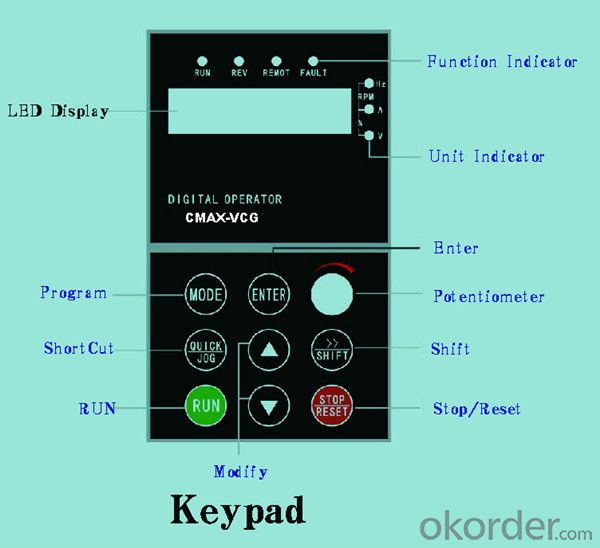

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: What is the difference between a frequency converter and a servo controller?

- The speed of an asynchronous motor is =60f/p.f, the frequency of alternating current, P is the pole, and the logarithm.60 is the number of seconds in a minute. As can be seen from the form, the number of poles has been fixed. The speed of the asynchronous motor is proportional to the frequency of the power supply. The frequency of the asynchronous motor is changed by changing the frequency of the power supply. This is the principle of variable frequency speed regulation

- Q: Surface grinder can add frequency converter, what are the advantages and disadvantages?

- The use of variable frequency speed control, you can simplify the gear, gearbox and other complex mechanical drag mechanism, high degree of automation, simple operation, easy maintenance.The frequency converter adopts the external terminal control, and the DC 0-10V signal issued by the numerical control system is fed into the frequency converter through the VI ACM terminal of the frequency converter, and the digital setting speed is controlled to the analog variable frequency output. The motor speed is controlled by the size of the voltage signal produced by the numerical control system.The frequency converter has voltage (DC0 - 10V), current analog input interface, and can be well matched with the control signal of CNC system.

- Q: Schneider 303 4KW frequency converter F 013 trouble shooting method

- According to the ATV303 user manual,The F013 is a motor overload fault and is triggered by excessive motor current.Suggest:1. monitor the running condition of the converter with the panel (whether the actual running current exceeds the limit)2. check the motor thermal protection settings and motor load (such as motor drive chain bearings, reducer, etc.).

- Q: What does 0L1 stand for?

- Inverter 0L1 stands for frequency converter fault code: OL1: motor overload (OL1) fault for the output current exceeds the overload capacity of the motor, then need to reduce the load.

- Q: What does Ro1c mean on a converter?

- Relay output converter dry contact signal, RO1C is the common end and RO1A is closed, RO1B is normally open, this set of contacts is prepared to run the factory setting output signal, power on self-test is completed can run the relay output signal. It can be modified to the output point of the signal such as fault and operation in the twenty-fourth set of parameters.

- Q: What is a frequency converter?

- Frequency conversion technology is born with the need of AC motor stepless speed regulation. After 1960s, the power electronic devices through SCR (SCR), GTO (gate turn off thyristor (BJT), bipolar power transistor), MOSFET (metal oxide semiconductor field effect transistor), SIT (static induction transistor), SITH (static induction thyristor (MGT), MOS control MCT (MOS) transistor, thyristor controlled), IGBT (insulated gate bipolar transistor), HVIGBT (high voltage insulated gate bipolar transistor) device to update the development process, to promote the continuous development of power electronics technology. The beginning of 1970s, PWM VVVF (PWMVVVF) control has aroused great attention. In 1980s, PWM mode optimization, as the core of frequency conversion technology, attracted people's interest and obtained many optimization models, among which the saddle wave PWM model was the best. Since the latter half of the 1980s, the VVVF inverters in developed countries such as the United States, Japan, Germany, Britain and other developed countries have already been put into the market and have been widely used.

- Q: What is the frequency converter through function?

- Frequency converter is an ideal motor stepless speed regulating device. It is mainly used in three-phase and two-phase asynchronous motors. It has the advantages of small start-up current, smooth operation and complete protection facilities. The utility model is suitable for stepless speed regulation of various equipment.

- Q: I do mining equipment, recently I used ABB frequency converter to put into our equipment, but the problem of interference really gives me a headache! We have two pieces of equipment of SIEMENS S7-200 PLC, and is used in point to point protocol communication with each other, when the converter work PLC communication interference! There are monitoring equipment, converter work, there are a large number of snowflakes on the screen, simply do not see! Not even an internal phone! I've done well in grounding, but I still can't do it! Is there any master who can teach me a trick?

- Solutions to interference caused by electromagnetic radiation:1. access reactor2., the correct grounding - grounding wire as close as possible to the frequency converter, the principle of power lines, frequency converter for the ground wire must be usedThe ground wire is separated from the other equipment, and the earthing of all the equipment must be avoided before grounding.The earthing terminal of the frequency converter can not be connected with the zero line.3. access filter.4. reduce carrier frequency.

- Q: How do you set the frequency with panels?. What are the specific steps?

- The parameter 700 is the starting signal, the 1 is a panel key starting, and the 2 is an external signal starting;The parameter 1000 is the frequency setting value, and the 1 is a panel lifting key, and the frequency is changed, and 2 is changed by the external analog signal.Your problem, the start signal is set up, finished, the parameter 1000 should be 1, so that the panel set frequency, and then set the parameter 1031 to 1, so that it automatically save the frequency changes after the value

- Q: Which brand of converter is better?

- Shanghai international shipping center Yangshan deep water port project, Shanghai Pudong Airport, Shanghai Hongqiao Airport, the Three Gorges project, Gansu satellite launch center, the south to North Water Diversion, the west east gas transmission, China Petroleum group,

Send your message to us

China best selling VFD Frequency Drive 3 phase 380V 55KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords