Frequency Inverter Single-phase 380V class 200KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

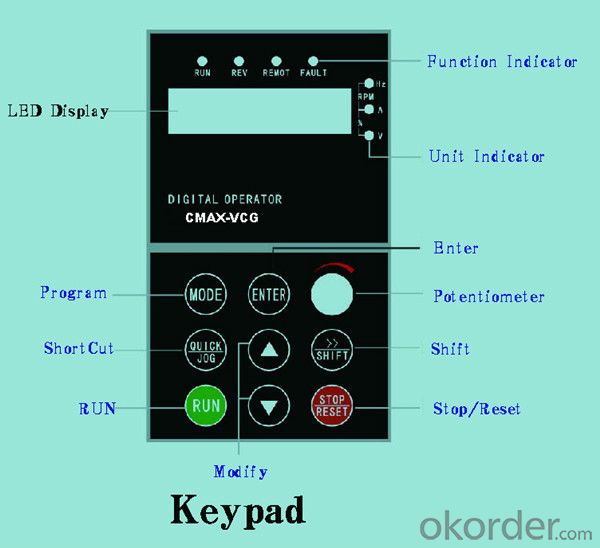

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: That is, some parameters of the inverter, such as torque, current, frequency, etc., are displayed on the Kingview software interface, but not through the PLC. The idea that the MODBUS protocol between SIEMENS and 200PLC has never been successful before, so that's the idea of the ABB. If it can be achieved,Is it necessary to write the script program on the Kingview, and what problems should I pay attention to when using the MODBUS protocol in Kingview software?The problem is a little bit more, I hope the experts teach me this rookie! Thank you

- As long as there are 485 communications can be, the frequency converter manual on the MODBUS protocol, the address of each parameter, in the king view on the link can do, and I hope to adopt.

- Q: What does the base frequency 60Hz represent in the inverter?

- How to set the frequency converter: inverter frequency parameter should be set to the rated frequency of the motor is set up, and not according to the load characteristic set, even if the selection is not suitable for motor load characteristics or parameters must also try to follow the motor, easy over-current or overload.

- Q: There is a feed and send system. Now due to the severity of the material is not the same as the two converters often change speed, the workers do not understand their own, often by, often bad now how to use the best way you can use a potentiometer or other method, control of the two frequency converter, synchronous operation. Is to adjust one, and the other also with the kind of frequency, so that you can let the workers themselves to open, and the two inverters, the same manufacturer, the same model, the same load,

- Two start with frequency conversion. The frequency converter is controlled by a potentiometer, and the analog output signal (AO.GND) is sent into the converter and connected to the AI.GND port of the converter. If the pulse port can also be connected to the pulse port.

- Q: The difference between soft starter and converter

- The soft starter is during the start-up of the equipment to take blood pressure or other ways to reduce the starting current of the inverter machine, the device is in operation according to the equipment load by changing the size of the power frequency and regulating equipment output.

- Q: How do two inverters synchronize?

- First of all, to determine whether the speed of the two conveyor is very strict (there is strict relative position requirements), if not, can use the following program:1. use a double potentiometer to tune two inverters simultaneously, one with a potentiometer to adjust the ratio between the two.

- Q: How can I control the frequency converter with a computer?

- RS232 communication can be used to control the frequency converter and other equipment, but there are several problems to be solved:1, frequency converter is generally two wire communication (422/485), so there must be 485/232 or 485/USB conversion.2, software problems, you can use VB, C, and with any of their own familiar with the method of preparation of a control interface, and in accordance with the frequency converter communication protocol written.3, also can buy ready-made configuration software, that saves the trouble of programming and debugging program.4, with computer communication with PLC (currently popular), and then use PLC and frequency converter communication (program is more simple and practical than using VB).

- Q: What are the possible causes of frequency hopping overload?

- The meaning of inverter overload protection is that the output current of the inverter continues to exceed the rated current, but it has not exceeded the transient flow point, and the general duration is defined as 1min. The general overload constant torque converter is 150% 1min, variable torque converter is generally 110%120%/1min.

- Q: What are the basis of the frequency converter to choose?

- According to the applied industry.The application of inverter industry RGB field is widely used, the main products are: SAJ-S simple ultra small, SAJ-M mini, SAJ-G universal, SAJ-F type, SAJ-P type wind pump, SAJ-Y injection molding machine type, SAJ-Z type, heavy machine industry, naked personalized products, high performance vector inverter S350.

- Q: How do you set the frequency with panels?. What are the specific steps?

- Concrete steps are:1, the parameter 700 is the starting signal, the 1 is the panel button starting, and the 2 is the external signal starting;2, the parameter 1000 is the frequency setting value, and the 1 is the panel lifting mark key to change the frequency, and 2 is the external analog signal change.3, the starting signal is set automatically, then the parameter 1000 is 1, the panel is set frequency, and the parameter 1031 is set to 1 so that the frequency value after the change is saved automatically.

- Q: What is the main harmonic produced by a transducer? How about the degree?

- Indirect frequency conversion has three different structure forms: (1) using controllable rectifier to change voltage, frequency conversion with inverter, voltage regulation and frequency modulation are carried out in two aspects respectively, and the two should coordinate with each other in control circuit. (2) with uncontrolled rectifier rectifier chopper inverter transformer, inverter, filter the inverter rectifier, voltage with pulse width (3) with uncontrolled rectifier rectifier, PWM inverter and inverter, this inverter device fully controlled only by controlled shutdown (such as IGBT) can output waveform is very realistic sine wave.

Send your message to us

Frequency Inverter Single-phase 380V class 200KW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords