China Best Selling VFD Frequency Drive Three Phase 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.220V Single Phase Variable Frequency Drive 2.2KW

2.Advanced control technology

3.Easy to operate

220V Single Phase Variable Frequency Drive 2.2KW

General

CNBM frequency inverter is a high-quality, multi-function,

low-noise variable frequency drive which is designed, developed and manufactured according to international standards.

It can meet different needs of industrial conditions.

The inverter applies advanced control technology of space voltage vector PWM, with functions of constant voltage control, power-off restart, dead zone compensation, automatic torque compensation, online modification parameter, high-speed impulse input, simple PLC and traverse.

Product Name:CMAX-VCG15/P18.5T3 ~ CMAX-VCG18.5/P22T3

Application

Textile: coarse spinner, spinning frame, wrap-knitting machine, loom, knitting machine, silk-spinning machine, etc.

Plastic: extruder, hauling machine, decorating machine, etc.

Pharmacy: mixer, roaster, etc.

Woodworking: engraving machine, sander, veneer peeling lathe, etc.

Papermaking: single type papermaking machine, etc.

Machine tool: non-core grinding machine, optical lens grinding machine, cutting mill, etc.

Printing: cloth-washing machine, dye vat, etc.

Cement: feeder, air blower, rotary furnace, mixer, crusher, etc

Fan and pump: kinds of fans, blowers and pumps

Specification

Item | Specification | |

Input | Input voltage | 220/380V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~input voltage |

Output frequency | 0~600Hz | |

Peripheral interface characteristics | Programmable digital input | 4 switch input, 1 high-speed impulse input |

Programmable analog input | AI1: 0~10V input AI2: 0~10V input or 0~20mA input, | |

Programmable open collector output | 2 Output (3.7kW and above: 1 Open collector output) | |

Relay Output | 1 Output (3.7kW and above: 2 Relay output) | |

Analog output | 2 Output, one is 0~10V, another is 0~20mA or 0~10V | |

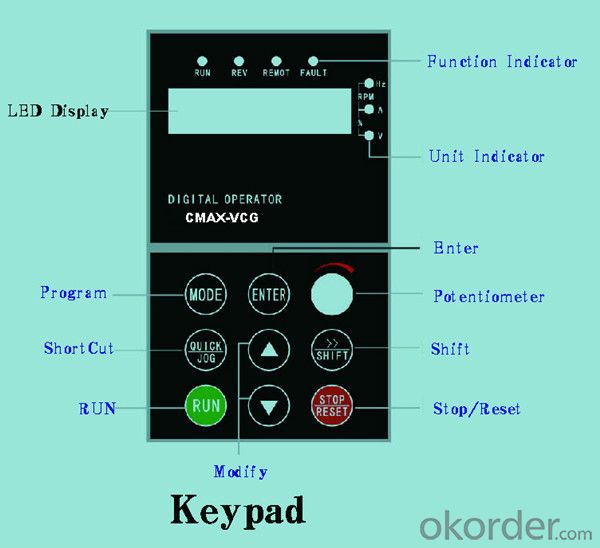

Keypad | Display:5-digit 8-section LED (Red), 2 indicators; parameter setting: 8 keys (including multi-function hot key ), 1 potentiometer | |

Technical performance characteristics | Control mode | All digital space voltage vector SVPWM algorism |

Overload capacity | G purpose: 150% rated current 60s P purpose: 120% rated current 60s | |

Speed ratio | 1: 100 | |

Carrier frequency | 1.0~10.0kHz | |

Torque compensation | Linear, multi-point, 1.3th power, 1.7th power, 2.0th power reduced torque; Compensation voltage range: automatic compensation and manual compensation 0.1~10% | |

Automatic voltage adjustment | It can automatically maintain output voltage constant when grid voltage fluctuates. | |

Automatic current adjustment | When the current is over current limit, under clocking automatically limits output current. | |

Function characteristics | Frequency setting mode | Keypad digital analog input, keypad potentiometer, impulse frequency, communication, multi-step speed and simple PLC, PID setting and so on, switch-over of setting modes. |

Simple PLC, multi-step speed control | 16-step speed control | |

Special function | Traverse control, length control, time control | |

QUICK/JOG key | User-defined multi-function hot key | |

Protection function | Over-current, Over voltage, under-voltage, over-heat, phase failure, over-load and motor over-load | |

Working condition | Installation site | Indoor, altitude of less than 1km, dust free, non-corrosive gases, no direct sunlight |

Application environment | -10°C~+40°C, 20~90%RH (no dew) | |

Vibration | Less than 0.5g | |

Storage temperature | -25°C~+65°C | |

Installation type | Wall-mounted type, floor cabinet type | |

Cooling mode | Air-forced cooling | |

- Q: Application of ABB frequency converter

- When the motor is powered by an industrial frequency power supply, the current increases when the voltage drops; for the inverter, if the voltage drops when the frequency drops, then does the current increase?When the frequency drops (low speed), if the output is the same power, the current increases, but the current remains almost constant under a certain torque.

- Q: What's the use of switching frequency of converter?

- The chopper device also has switching life, the higher the switching frequency, the shorter the life of the inverter, and will reduce the inverter output current and power. The smaller the chopping frequency, the higher harmonic content and the more serious harmonic pollution.

- Q: At the base block Yaskawa inverter is what reason?

- Garbage in Yaskawa signal board on the small line contact oxidation, look good, this is a kind of weak signal, and for safety relay is not the safety loop at high levels in a small line short circuit, 1000 Yaskawa A factory is shorted for a long time have blocked the oxidation base

- Q: How does the frequency converter change the voltage and change the speed of the motor?

- In reducing the power frequency, the frequency converter must be reduced at the same time the power supply voltage, this is because, for the asynchronous motor, the phase voltage is proportional to the product of frequency and magnetic flux, when the frequency is reduced, if the voltage is constant, the flux will increase, it is easy to cause the magnetic saturation, excitation current surge, causing the motor to burn.The general frequency converter will automatically adjust the output voltage at the same time as the frequency is changed. What do you need to do without additional operation?.

- Q: The frequency converter is in use suddenly the speed reduces, then the debugging is out of control, how to do?

- The average DC voltage Ud=1.35U line =513V is calculated by the 380V line voltage. When the overvoltage occurs, the energy storage capacitor on the DC bus will be charged, and when the voltage rises to about 700V, due to different models, the converter will protect the voltage. There are two main causes of over voltage: over voltage and over voltage.

- Q: The difference between soft starter and converter

- The soft starter is during the start-up of the equipment to take blood pressure or other ways to reduce the starting current of the inverter machine, the device is in operation according to the equipment load by changing the size of the power frequency and regulating equipment output.

- Q: There is much dust and moisture in my workshop. Many brands are not durable.

- ABB inverter is of high quality, but it requires a lot of environment, such as dust and humidity in your workshop. It is too bad for ABB inverters. You can try to use the seal of inverter, it is designed according to the use environment of inverter in various industries, mainly considering China's current converter relatively harsh environment (water vapor, dust, oil, metal powder, corrosive gas), in CNC lathe, grinding machine chemical plant, reaction kettle, blender, textile machinery, printing and dyeing equipment, water pump, industrial washing machine, dehydration machine where the effect is very good.

- Q: If you don't plug in the PG card, do you use PLC's PID control?Plug in the PG card and the PLC PID control, which is reliable and precise?

- If there is a PLC encoder as a speed sensor signal, you can access the PLCPLC analog output (or communication) as a given value of the inverterUse PLC's PID instruction to complete the speed closed loop control of the converter.Note: if you are not using vector control of the inverter, you can.For example: horizontal transmission of non vector control or pump fan class.

- Q: What is the main harmonic produced by a transducer? How about the degree?

- The main hazards are:(1) the possibility of resonance in the power grid is increased, thereby causing high overvoltages or overvoltages to cause the risk of accidents.(2) increasing additional losses, efficiency of transmission and electrical equipment, and utilization of equipment.(3) make the electrical equipment (rotating motor, capacitor, transformer, etc.) run abnormally, accelerate the insulation aging, and shorten their service life.

- Q: What do you mean by the capacity of the inverter and the capacity of the motor?

- That's not the case at all"Capacity" and "power" are essentially different. Usually we say that a large transformer capacity is how much KVA, but not to say how much KW, because the two are not the same thing

Send your message to us

China Best Selling VFD Frequency Drive Three Phase 380V

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches