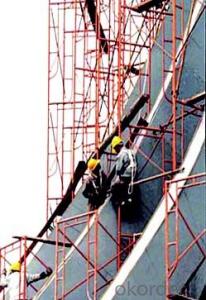

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

- Q: What safety measures should be taken when using steel frame formwork?

- To ensure workers' well-being and prevent accidents or injuries, it is essential to implement various safety precautions when utilizing steel frame formwork. Here are some important measures to consider: 1. Personal Protective Equipment (PPE): All workers must wear suitable PPE, such as hard hats, safety goggles, gloves, and steel-toed boots, to protect against potential hazards like falling objects and sharp edges. 2. Training and Competency: Workers should receive adequate training and demonstrate competence in using the steel frame formwork system. This includes understanding assembly, dismantling, and usage procedures, as well as safe handling techniques, load limits, and proper tool and equipment usage. 3. Inspection and Maintenance: Regular inspections and maintenance of the steel frame formwork are crucial to identify any defects or damage that could compromise its structural integrity. This includes checking for cracks, rust, misalignments, loose or missing components, and signs of wear and tear. Prompt repairs or replacements should be carried out for damaged or faulty parts. 4. Proper Assembly and Dismantling: The steel frame formwork must be assembled and dismantled correctly, following the manufacturer's instructions and guidelines. Experienced and trained personnel should undertake these tasks to ensure stability and prevent accidents. Adequate bracing and support should be implemented during assembly to prevent collapse or movement. 5. Secure Fixing: The steel frame formwork should be securely fastened to the structure using appropriate clamps, bolts, or other fastening mechanisms. This will prevent any movement or displacement during concrete pouring or other construction activities. 6. Load Limits: Adhering to the load limits specified by the manufacturer is crucial. Overloading the steel frame formwork can result in structural failures or collapse. Therefore, the weight of the concrete, construction materials, and workers should be carefully calculated and monitored to avoid exceeding the maximum load capacity. 7. Fall Protection: Proper fall protection systems, such as guardrails, safety nets, or personal fall arrest systems, should be in place to prevent falls from heights. This is particularly important when workers are operating on elevated platforms or platforms with openings. 8. Communication and Coordination: Clear communication and coordination among workers are essential to creating a safe working environment. This includes providing instructions, warnings, and signals to prevent accidents and ensure a smooth workflow. By implementing these safety measures, the risk of accidents, injuries, and structural failures can be significantly reduced when using steel frame formwork. Prioritizing safety and providing ongoing training and supervision to all personnel involved in the construction process are crucial aspects to consider.

- Q: How does steel frame formwork ensure proper alignment and positioning of concrete structures?

- Steel frame formwork ensures proper alignment and positioning of concrete structures through its strong and rigid construction. The steel frames are designed to be sturdy and stable, providing a reliable support system for the concrete during the pouring and curing process. Firstly, steel frame formwork is assembled in a way that allows for accurate and precise measurements. The frames are typically pre-fabricated and can be easily adjusted and aligned to meet the required dimensions of the structure. This ensures that the concrete will be poured and set in the correct position, preventing any misalignment or deviations from the intended design. Additionally, steel frame formwork provides a level and smooth surface for the concrete to be poured onto. The frames are designed to be flat and even, ensuring that the concrete will be evenly distributed and not settle in any particular area. This helps to maintain the overall integrity and strength of the structure, as well as prevent any potential issues that may arise from uneven pouring. Furthermore, steel frame formwork offers a stable and secure support system for the concrete. The frames are typically reinforced with bracing and tie rods, which help to hold everything in place during the pouring and curing process. This prevents any shifting or movement of the concrete, ensuring that it sets and cures in the desired position. Overall, steel frame formwork plays a crucial role in ensuring the proper alignment and positioning of concrete structures. Its strong and rigid construction, accurate measurements, level surface, and stable support system all contribute to a successful and well-built concrete structure.

- Q: How does steel frame formwork handle the placement of landscaping and outdoor features within the concrete structure?

- Steel frame formwork is a versatile system that can easily accommodate the placement of landscaping and outdoor features within the concrete structure. With its flexible design and adjustable panels, the formwork can be customized to create openings or voids for trees, plants, or other elements to be integrated seamlessly. Additionally, the steel frame provides excellent support and stability, ensuring that the landscaping and outdoor features are securely embedded in the concrete structure.

- Q: What safety precautions should be taken when using steel frame formwork?

- When using steel frame formwork, it is important to ensure the following safety precautions are taken: 1. Properly train all workers on the correct handling and installation of steel frame formwork to avoid accidents and injuries. 2. Wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and steel-toed boots to protect against potential hazards. 3. Inspect the steel frame formwork for any defects or damage before use, and repair or replace any compromised components. 4. Securely anchor the formwork to prevent any movement or collapse during concrete pouring or other construction activities. 5. Regularly inspect and maintain the formwork to ensure its stability and structural integrity. 6. Implement proper fall protection measures such as guardrails, safety nets, or harnesses when working at heights. 7. Communicate and coordinate with other workers on the construction site to ensure everyone is aware of the formwork and any potential risks associated with its use. 8. Follow all manufacturer's instructions and guidelines for the safe use of steel frame formwork. By following these safety precautions, the risk of accidents, injuries, and structural failures can be minimized when using steel frame formwork.

- Q: Can steel frame formwork be used in tight construction spaces?

- Yes, steel frame formwork can be used in tight construction spaces. Steel frame formwork is highly versatile and can be easily adjusted or modified to fit into narrow or limited spaces. Its compact design allows for efficient use of space, making it suitable for tight construction areas where traditional formwork may not be feasible.

- Q: How is steel frame formwork assembled and disassembled?

- Steel frame formwork is assembled by first constructing the steel frames and securing them in place using connectors and fasteners. Next, plywood or other formwork material is attached to the frames. Once the concrete pouring is complete and the concrete has cured, the formwork is disassembled by removing the plywood panels and detaching the connectors and fasteners. The steel frames can then be dismantled and reused for future construction projects.

- Q: How does steel frame formwork accommodate for different concrete mix designs?

- Steel frame formwork can accommodate for different concrete mix designs by allowing for easy adjustment of the formwork panels. This means that the size and shape of the formwork can be modified to accommodate variations in the concrete mix design, such as different slump levels or aggregate sizes. Additionally, the steel frame formwork provides stability and strength, ensuring that it can withstand the pressure exerted by different concrete mix designs during pouring and curing.

- Q: Are there any restrictions on the thickness of the concrete that can be poured using steel frame formwork?

- Yes, there are restrictions on the thickness of concrete that can be poured using steel frame formwork. The thickness usually depends on the design and specifications of the steel formwork system being used. It is important to consult the manufacturer or design engineer to determine the maximum recommended thickness for pouring concrete using steel frame formwork.

- Q: Can steel frame formwork be used for both reinforced and non-reinforced concrete?

- Yes, steel frame formwork can be used for both reinforced and non-reinforced concrete. Steel frame formwork is a versatile and durable system that can be easily adjusted and reused for various concrete structures. The steel frames provide strong support and stability, allowing for the pouring and shaping of both reinforced and non-reinforced concrete. This type of formwork system is commonly used in construction projects that require different types of concrete structures, such as foundations, walls, columns, and beams. The flexibility and strength of steel frame formwork make it suitable for accommodating the specific requirements of reinforced and non-reinforced concrete construction.

- Q: How does steel frame formwork handle the removal of formwork after concrete curing?

- In the construction industry, steel frame formwork is highly favored due to its durability and strength. When it comes to removing formwork after concrete has cured, steel frame formwork offers numerous benefits. To begin with, steel frame formwork is designed for easy disassembly and removal. The formwork system comprises interconnected steel frames that utilize various fastening mechanisms like clamps or bolts. This facilitates a swift and efficient dismantling process, minimizing downtime and labor costs. Furthermore, steel frame formwork boasts exceptional load-bearing capacity. It can support the weight of the concrete during the curing process, eliminating the need for additional supports. Consequently, removing the formwork is relatively straightforward as the steel frames can be safely lifted and detached without compromising the integrity of the concrete structure. Moreover, steel frame formwork is reusable, making it a cost-effective option. Once the formwork is removed, it can be cleaned, inspected, and prepared for future projects. This not only reduces material waste but also saves money on purchasing new formwork for each construction project. Additionally, steel frame formwork ensures a smooth and even finish on the concrete surface. The rigid and stable design of the steel frames guarantees that the concrete retains its shape and structure throughout the curing process. This results in a high-quality finish, reducing the need for additional surface treatments or repairs after removing the formwork. Overall, steel frame formwork is a dependable and efficient solution for handling formwork removal after concrete has cured. Its ease of disassembly, load-bearing capacity, reusability, and ability to produce a smooth finish make it the preferred choice for construction projects.

Send your message to us

Frame Scaffolding Formwork Thickness of Scaffolding Pipe Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords