Frame Connected Economical Efficiency Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

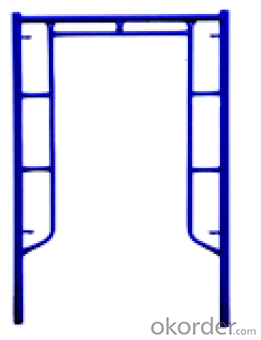

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Images

4. Specification

Maximum breaking load: 22.2t

Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel tube couplers be used in scaffolding projects with limited access to lifting equipment?

- Yes, steel tube couplers can be used in scaffolding projects with limited access to lifting equipment. Steel tube couplers are designed to securely connect scaffolding tubes without the need for welding or additional lifting equipment. They provide a strong and reliable connection, making them suitable for scaffolding projects in areas where lifting equipment may not be readily available or accessible.

- Q: What are the common warranty terms for steel tube couplers in scaffolding?

- The common warranty terms for steel tube couplers in scaffolding typically include a warranty period of one year from the date of purchase. During this period, the couplers are warranted to be free from defects in material and workmanship. However, the warranty does not cover damage caused by misuse, improper installation, or normal wear and tear. It is important to read and understand the specific warranty terms provided by the manufacturer or supplier of the steel tube couplers.

- Q: Are steel tube couplers compatible with scaffolding projects involving multiple levels?

- Yes, steel tube couplers are compatible with scaffolding projects involving multiple levels. Steel tube couplers are used to connect and secure steel tubes in scaffolding structures. They are designed to provide a strong and reliable connection, ensuring the stability and safety of the scaffolding system. Whether it is a single-level or multi-level scaffold, steel tube couplers can be used to create a secure and durable structure. Additionally, steel tube couplers offer flexibility in terms of adjusting the height and configuration of the scaffold, making them suitable for projects involving multiple levels. Overall, steel tube couplers are a versatile and compatible component for scaffolding projects of any scale or complexity.

- Q: Are steel tube couplers reusable or designed for single-use only?

- Steel tube couplers have been specifically engineered for reusability. These couplers are commonly employed in a wide range of applications, including scaffolding, construction, and engineering projects, to effectively join steel tubes together. They are manufactured using robust materials like steel and are adept at withstanding heavy loads while providing a dependable connection between tubes. The cost-effectiveness and practicality of steel tube couplers lie in their ability to be reused multiple times. Unlike certain other couplers or connectors that are intended for single-use only, steel tube couplers can be easily dismantled and reinstalled whenever necessary. This adaptability facilitates efficient assembly and disassembly of structures, making them particularly advantageous for temporary or adjustable installations. Additionally, the durability of steel tube couplers guarantees that they can endure repeated usage without compromising their performance or safety. This attribute is especially significant in industries wherein structures need to be frequently constructed and dismantled, or where adjustments and modifications are required. Nevertheless, it is crucial to emphasize the importance of proper inspection and maintenance when reusing steel tube couplers. Regular examinations must be carried out to identify any indications of wear, corrosion, or damage that could jeopardize their integrity. If any issues are detected, it is imperative to replace the couplers to ensure the safety of the structure. In conclusion, steel tube couplers have been designed with reusability in mind and can offer a secure and dependable connection between steel tubes. Their durability, flexibility, and cost-effectiveness render them an excellent choice for various applications that necessitate frequent assembly and disassembly of structures.

- Q: Are steel tube couplers compatible with different scaffold tube sizes?

- Yes, steel tube couplers are designed to be compatible with different scaffold tube sizes. They are adjustable and can be used to connect tubes of varying diameters securely and safely.

- Q: Are steel tube couplers compatible with different types of scaffolding planks or platforms?

- Different types of scaffolding planks or platforms can be connected using steel tube couplers. These couplers are versatile and can be used to join various components of the scaffold structure, such as planks or platforms. Their purpose is to securely fasten the planks or platforms to the scaffold tubes, ensuring stability and safety during construction or maintenance activities. Steel tube couplers can be used to connect planks or platforms made of wood, aluminum, or other materials to the scaffolding system. This compatibility has made steel tube couplers a popular choice for scaffolding applications because they provide a reliable and flexible solution for working at height.

- Q: Are there any specific maintenance requirements for steel tube couplers in scaffolding?

- Yes, there are specific maintenance requirements for steel tube couplers in scaffolding. These couplers should be regularly inspected for any signs of damage, such as cracks or corrosion. They should also be cleaned and lubricated to ensure smooth functioning and prevent rusting. Additionally, it is important to follow the manufacturer's guidelines for load capacities and proper usage to maintain the safety and integrity of the scaffolding structure.

- Q: Are steel tube couplers suitable for scaffolding applications in extreme weather conditions?

- Yes, steel tube couplers are suitable for scaffolding applications in extreme weather conditions. Steel is known for its strength and durability, making it highly reliable even in harsh weather conditions such as heavy rain, strong winds, or extreme temperatures. Steel tube couplers provide a secure and stable connection between scaffold tubes, ensuring the safety and stability of the scaffolding structure even in challenging weather conditions.

- Q: Can steel tube couplers be used for scaffolding systems that require high resistance to impact?

- Yes, steel tube couplers can be used for scaffolding systems that require high resistance to impact. Steel is a strong and durable material, making it suitable for withstanding impact and providing a secure connection between scaffolding tubes. Additionally, steel tube couplers are designed to meet specific safety standards and regulations, ensuring their reliability in high-impact environments.

- Q: they cover the side walk and have like metal bars on the edge facing the street

- They are called sidewalk sheds or sidewalk bridges and are used to protect pedestrians from falling debris. Usually this is a construction site, but can be where the building is in bad shape and inherently dangerous.

Send your message to us

Frame Connected Economical Efficiency Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches