Frame-Connected Scaffolding of Massive Power and Resouce Saving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

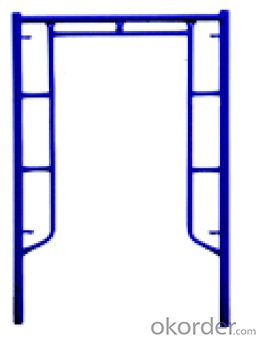

1. Structure of Frame-Connected Scaffolding

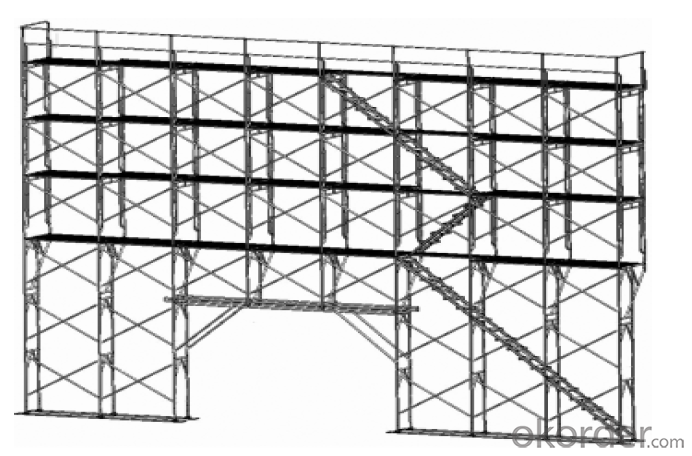

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

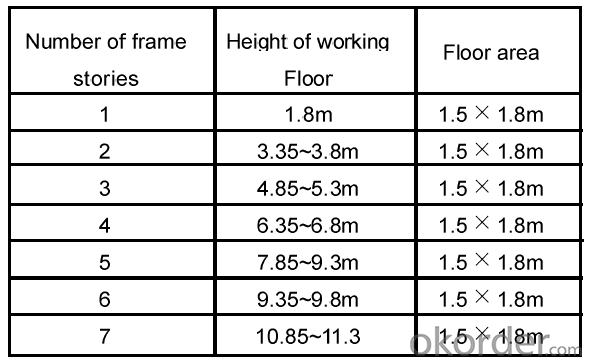

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Are steel tube couplers adjustable for different angles in scaffolding with limited headroom?

- Yes, steel tube couplers are adjustable for different angles in scaffolding with limited headroom. Steel tube couplers are designed to connect scaffolding tubes at various angles, allowing for flexibility in scaffolding configurations. These couplers typically have a swivel or adjustable mechanism that allows for easy adjustment of the angle while maintaining stability and strength. This feature is particularly useful in situations where there is limited headroom, as it enables scaffolding to be erected in tight spaces or under low ceilings. By adjusting the angle of the couplers, scaffolding can be set up to fit the specific requirements of the job site, ensuring safety and efficiency in the construction or maintenance project.

- Q: What are the potential risks or hazards associated with using steel tube couplers in scaffolding?

- Using steel tube couplers in scaffolding can be associated with several potential risks or hazards. One primary risk is the possibility of structural failure. If the couplers are not installed properly or if they exceed their recommended weight capacity, they may fail, leading to the collapse of the scaffolding structure. Such an event can cause severe injuries or even fatalities for workers or those nearby. Another risk is the potential for coupler slippage. If the couplers are not securely tightened, there is a chance that they may slip or become loose, resulting in instability in the scaffolding. This can cause workers to lose their balance and fall from heights, resulting in severe injuries. Improper use of steel tube couplers can also be hazardous for workers. If the couplers are not used in accordance with the manufacturer's instructions or industry standards, it can compromise the stability and integrity of the scaffolding system. This can create an unsafe working environment and increase the likelihood of accidents or injuries. Moreover, there is a risk of electrocution if steel tube couplers come into contact with live electrical wires or power sources. This can occur if the scaffolding is not adequately insulated or if workers accidentally make contact with electrical hazards while assembling or disassembling the scaffolding structure. Furthermore, the weight and bulkiness of steel tube couplers can make them difficult to handle and maneuver, especially when working at heights. If not handled properly, they can cause strain or injury to workers, leading to musculoskeletal disorders or accidents. To mitigate these risks, it is vital to ensure correct installation of all steel tube couplers, regular inspection for any signs of wear or damage, and adherence to specified weight capacities. Workers should receive training on the proper assembly and disassembly of scaffolding structures, as well as the safe handling of steel tube couplers. Regular safety inspections and maintenance should be conducted to ensure the integrity of the scaffolding system and minimize the risk of accidents or hazards.

- Q: What is the maximum load capacity of steel tube couplers?

- The maximum load capacity of steel tube couplers depends on various factors such as the size and design of the coupler, the type of steel used, and the specific application it is being used for. It is recommended to consult the manufacturer or refer to the product specifications to determine the exact maximum load capacity of a particular steel tube coupler.

- Q: A 67.0kg- painter is on a uniform 23kg- scaffold supported from above by ropes. There is a 3.6kg- pail of paint to one side, as shown .

- Painter Scaffold

- Q: Can steel tube couplers be used in temporary scaffolding structures?

- Yes, steel tube couplers can be used in temporary scaffolding structures. Steel tube couplers are commonly used in scaffolding systems to securely connect steel tubes together, ensuring the stability and strength of the scaffolding structure. These couplers are designed to provide a reliable and durable connection, making them suitable for temporary scaffolding structures.

- Q: A JGJ130-2011 "construction of fastener-type steel scaffold safety technical specifications" and a hungry hunger thirsty leek tortoise feathers JGJ59-2011 "construction enterprises to check the scoring standard" extremely grateful! E-mail: more

- Wxtjtsy has been sent, please adopt it promptly, thanks

- Q: Can steel tube couplers be used in scaffolding projects with curved or inclined structures?

- Yes, steel tube couplers can be used in scaffolding projects with curved or inclined structures. These couplers are designed to connect steel tubes at various angles, allowing for flexibility and adaptability in scaffolding systems. They provide a secure and reliable connection, ensuring the stability and safety of the scaffolding structure, even in curved or inclined configurations.

- Q: Can steel tube couplers be used in conjunction with other scaffolding accessories?

- Yes, steel tube couplers can be used in conjunction with other scaffolding accessories. They are designed to connect and secure steel tubes together, allowing for the construction of versatile scaffolding structures.

- Q: Are steel tube couplers resistant to vibration or shaking?

- Steel tube couplers are known for their resistance to vibration and shaking in general. With its strength and durability, steel is capable of enduring various forces, including vibrations and shaking. These couplers are specifically designed to securely connect steel tubes, ensuring a stable and trustworthy connection. They find extensive use in construction, engineering, and manufacturing industries, where stability and resistance to vibrations are crucial. Nevertheless, it is worth noting that the level of resistance may differ based on the particular design and quality of the steel tube couplers employed.

- Q: Can steel tube couplers be used for both straight and angled connections in scaffolding?

- Steel tube couplers have the capability to be utilized for both straight and angled connections in scaffolding. They possess versatility and enable the joining of steel tubes at different angles, thereby facilitating the construction of multi-directional scaffolding structures. These couplers are specifically engineered to establish a steadfast and dependable connection, guaranteeing the stability and safety of the scaffolding system. Regardless of whether it is for straight or angled connections, steel tube couplers are a prevalent and extensively employed element in the construction of scaffolding.

Send your message to us

Frame-Connected Scaffolding of Massive Power and Resouce Saving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches