Frame-Connected Reasonable and Practical Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

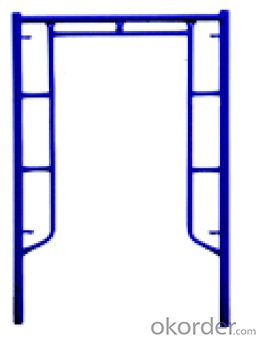

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

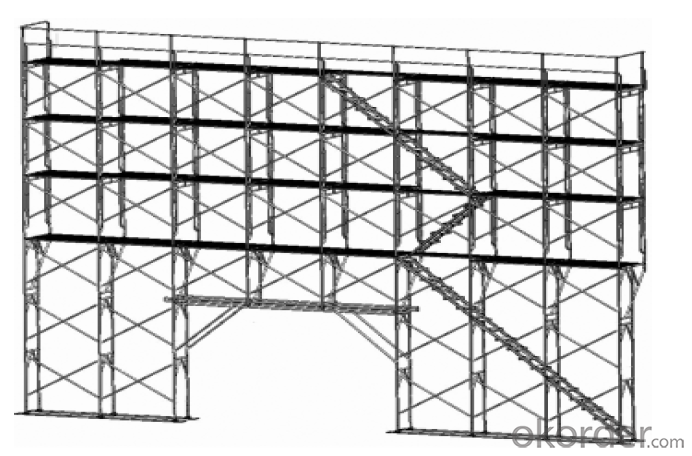

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

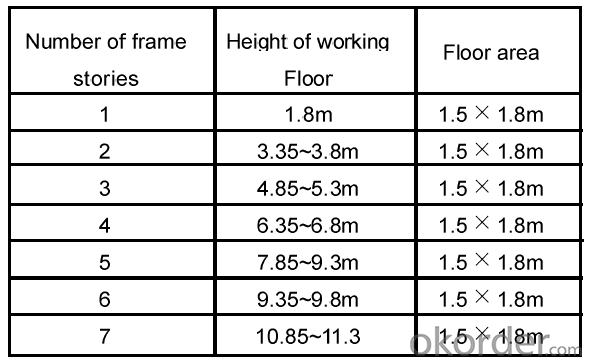

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel tube couplers be used for scaffolding projects that involve working in confined spaces?

- Yes, steel tube couplers can be used for scaffolding projects that involve working in confined spaces. Steel tube couplers are commonly used in scaffolding systems as they provide a strong and secure connection between tubes, ensuring the stability and safety of the construction. Their compact size makes them suitable for use in confined spaces where larger couplers may not fit. However, it is essential to consider all safety regulations and guidelines specific to working in confined spaces to ensure the overall safety of the project.

- Q: How do steel tube couplers ensure proper load distribution and stability in scaffolding structures with irregular or unbalanced loads?

- Steel tube couplers play a crucial role in ensuring proper load distribution and stability in scaffolding structures, even when dealing with irregular or unbalanced loads. These couplers are specifically designed to connect and secure steel tubes, creating a strong and reliable framework. One way steel tube couplers ensure load distribution is by evenly distributing the weight across multiple tubes. Irregular or unbalanced loads can exert different forces on the scaffolding structure, which may cause instability if not properly distributed. By connecting the tubes with couplers, the load is spread out and shared between the tubes, preventing any one tube from bearing an excessive amount of weight. Additionally, steel tube couplers provide stability by effectively transferring forces and loads between the tubes. When irregular or unbalanced loads are applied to the scaffolding structure, there is a risk of twisting or bending that can compromise its stability. However, by using couplers, the forces and loads are transmitted between the tubes, ensuring that the structure remains stable and secure. Moreover, steel tube couplers offer versatility in accommodating different configurations and angles. In scaffolding structures with irregular or unbalanced loads, it may be necessary to connect tubes at various angles or positions. Couplers allow for flexibility in connecting these tubes together, enabling the scaffolding to adapt to the specific load requirements and maintain stability. Lastly, the strength and durability of steel tube couplers play a significant role in ensuring proper load distribution and stability. These couplers are typically made from high-quality steel, which provides the necessary strength and rigidity to withstand heavy loads and maintain structural integrity. The secure connection between the tubes, facilitated by the couplers, prevents any shifting or movement that could compromise the stability of the scaffolding structure. In conclusion, steel tube couplers ensure proper load distribution and stability in scaffolding structures with irregular or unbalanced loads by evenly distributing the weight, transferring forces between tubes, accommodating different configurations, and providing strength and durability. These couplers are essential components that contribute to the safety and reliability of scaffolding systems, allowing them to withstand challenging load conditions.

- Q: I'm thinking about getting my scaffold pierced but I've been researching and quite a few people have said that they had trouble with bleeding, also how much does it hurt? I have already had my ears done 3 times, my tragus, rook, lower cartilage, nose (with a gun), belly and tongue (all without freezing), how much does it hurt in comparisson?? thanks x

- Mine did bleed considerably more than any of my other piercings, including my microdermal. This said, it was mainly the second piercing I had trouble with, and it stopped after about a week, I think it mainly as when the second hole is pierced there is already increased blood flow to the ear due to the first hole. It bleeds a fair bit but not so much you need to stay indoors with a bandage on it or anything. Mine hurt a lot less than my rook, it was comparable to my tragus, but there's two piercing. The second one potentially hurt slightly more than the first, but it was only minor pain. good luck :)

- Q: Are steel tube couplers compatible with scaffolding edge protection systems for inclined surfaces?

- Yes, steel tube couplers are compatible with scaffolding edge protection systems for inclined surfaces. They can be easily attached to the scaffolding structure to provide a secure and safe edge protection solution, even on inclined surfaces.

- Q: Can steel tube couplers be used in confined spaces scaffolding projects?

- Yes, steel tube couplers can be used in confined spaces scaffolding projects. Steel tube couplers are commonly used in scaffolding systems to securely connect tubes and provide stability. They are versatile and can be used in various project environments, including confined spaces, as long as they are properly installed and meet safety regulations.

- Q: Can steel tube couplers be used in scaffolding projects with delicate surfaces?

- Steel tube couplers can be used in scaffolding projects with delicate surfaces, but precautions should be taken to protect the surface from any potential damage. One way to do this is by using protective materials such as rubber or foam padding on the couplers or any contact points between the scaffolding and the delicate surface. Additionally, it is important to ensure that the scaffolding is properly erected and stabilized to minimize any movement or vibration that could cause damage. Regular inspections should also be conducted to identify and address any potential issues or damage to the delicate surface. Overall, while steel tube couplers can be used in these projects, it is important to take extra care to protect the delicate surfaces and prevent any damage.

- Q: What are the potential consequences of using damaged or faulty steel tube couplers in scaffolding?

- Using damaged or faulty steel tube couplers in scaffolding can have serious consequences. Firstly, there is a risk of structural collapse. Steel tube couplers are an essential component in scaffolding, as they connect and support the tubes, forming a stable structure. If these couplers are damaged or faulty, they may not provide the necessary strength and stability, leading to a potential collapse of the scaffolding. This can result in injuries or even fatalities for workers or anyone nearby. Secondly, there is an increased risk of accidents and falls. When the couplers are not functioning properly, they may not securely hold the tubes together. This can cause instability in the scaffolding, making it more likely for workers to slip, trip, or fall from heights. Falls from scaffolding can lead to severe injuries, such as broken bones, head trauma, or spinal cord damage. Furthermore, using damaged or faulty steel tube couplers can compromise the overall integrity of the scaffolding system. The couplers play a crucial role in distributing the weight and load across the structure. If these couplers are not in good condition, the weight distribution may become uneven, causing certain areas of the scaffolding to bear excessive weight. This can lead to the failure of specific sections, further increasing the risk of collapse. Moreover, damaged or faulty couplers can affect the stability and balance of the scaffolding. Uneven or loose connections can cause the scaffolding to become wobbly or sway, making it unsafe for workers to move around or perform their tasks. This instability can also make it difficult to safely transport materials and equipment on the scaffolding, increasing the likelihood of accidents or injuries. Lastly, using damaged or faulty steel tube couplers can result in legal and financial consequences. Regulatory bodies, such as occupational health and safety organizations, have strict guidelines and regulations regarding the use of scaffolding equipment. If it is found that damaged or faulty couplers were used, the responsible parties may face penalties, fines, or legal actions. Additionally, the cost of potential injuries, property damages, or lawsuits can have a significant financial impact on the individuals or companies involved. In conclusion, using damaged or faulty steel tube couplers in scaffolding can have severe consequences. It can result in structural collapse, accidents, falls, compromised integrity, instability, and legal or financial repercussions. It is crucial to regularly inspect and maintain the scaffolding equipment to ensure the safety of workers and the surrounding environment.

- Q: who invented the scaffold?

- Like paper [meaning wood pulp based paper, not papyrus], blackpowder, and many other things, I would guess it is the Chinese. To this day they don't bother with metal for scaffolding, they use bamboo--even when building skyscrapers.

- Q: What are the potential drawbacks or limitations of using steel tube couplers in scaffolding?

- Some potential drawbacks or limitations of using steel tube couplers in scaffolding include: 1. Weight: Steel tube couplers can add significant weight to the overall scaffolding structure, making it more difficult to transport and set up. 2. Cost: Steel tube couplers can be expensive compared to other types of scaffolding connectors, increasing the overall cost of scaffolding projects. 3. Corrosion: Steel is susceptible to corrosion, especially in outdoor or humid environments. Regular maintenance and proper coating are necessary to prevent rust and ensure the longevity of the scaffolding structure. 4. Rigidity: Steel tube couplers can be rigid, limiting the flexibility and adaptability of the scaffolding system. This can be a drawback when working on uneven surfaces or complex structures. 5. Safety: If not properly installed or maintained, steel tube couplers may pose a safety risk. Structural failures, such as coupler slippage or detachment, can result in accidents or injuries. Overall, while steel tube couplers are widely used in scaffolding due to their strength and durability, it is important to consider these potential drawbacks and limitations before choosing them for a specific project. Alternatives like aluminum or plastic couplers may be more suitable in certain situations.

- Q: How do steel tube couplers prevent scaffolding tubes from separating or disconnecting under load?

- Steel tube couplers prevent scaffolding tubes from separating or disconnecting under load by providing a secure and reliable connection between the tubes. They are designed to grip and hold the tubes firmly together, ensuring that they remain connected even when subjected to heavy loads or external forces. The couplers typically have internal teeth or gripping mechanisms that engage with the surface of the tubes, creating a strong and stable joint. This prevents any movement or slipping between the tubes, thus ensuring the structural integrity and safety of the scaffolding system.

Send your message to us

Frame-Connected Reasonable and Practical Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches