Frame-Connected Adjustable and Safety Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

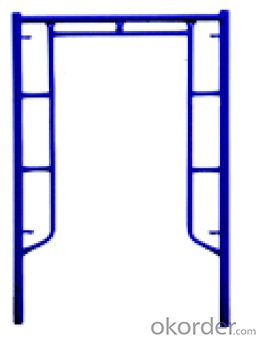

1. Structure of Frame-Connected Scaffolding

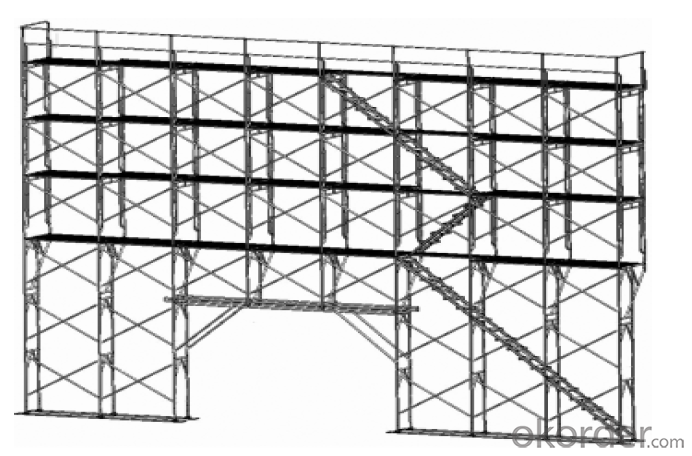

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

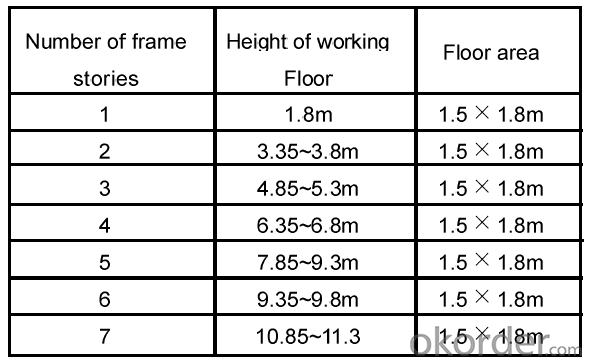

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How do steel tube couplers contribute to the overall durability of a scaffolding structure?

- Steel tube couplers are an essential component in scaffolding structures, contributing significantly to their overall durability. These couplers are designed to securely connect steel tubes together, forming a rigid and stable framework that can withstand heavy loads and adverse weather conditions. One way in which steel tube couplers enhance the durability of a scaffolding structure is through their exceptional strength and load-bearing capabilities. These couplers are typically made from high-quality steel, which provides superior strength and resilience. When properly tightened, they create a strong and rigid connection between the tubes, ensuring the stability and integrity of the entire structure. This ability to withstand substantial loads is crucial in scaffolding, as it ensures the safety of workers and the overall stability of the platform. Furthermore, steel tube couplers offer excellent resistance to corrosion and rust. Scaffolding structures are often exposed to various environmental elements, such as rain, humidity, and exposure to chemicals. Over time, these factors can cause rust and corrosion, which weaken the structure and compromise its durability. However, steel tube couplers are typically galvanized or coated with protective layers, making them highly resistant to corrosion. This added protection significantly increases the lifespan of the scaffolding structure, reducing maintenance requirements and ensuring long-term durability. Another important aspect of steel tube couplers is their versatility and adaptability. These couplers come in various types and designs, allowing for easy assembly and disassembly of the scaffolding structure. Their quick and efficient installation process ensures that the structure can be erected and dismantled with ease, reducing downtime and increasing productivity. This versatility also enables scaffolding structures to be customized and adjusted to different heights and configurations, making them suitable for various construction projects. In conclusion, steel tube couplers are integral to the overall durability of a scaffolding structure. Their strength, resistance to corrosion, and versatility contribute significantly to the stability and longevity of the scaffolding, ensuring the safety of workers and the structural integrity of the platform.

- Q: Can steel tube couplers be used for both internal and external scaffolding applications?

- Steel tube couplers have the ability to be utilized for both internal and external scaffolding purposes. These couplers are highly adaptable and can establish connections between steel tubes in diverse arrangements, resulting in the creation of scaffolding structures. Whether the intention is to construct a temporary platform within a building or to build a scaffold around the exterior of a structure, steel tube couplers are an exceedingly dependable and frequently employed component. By offering a secure and inflexible linkage between steel tubes, they guarantee the stability and safety of the scaffolding system.

- Q: Can steel tube couplers be used in combination with other scaffolding connection methods?

- Yes, steel tube couplers can be used in combination with other scaffolding connection methods. Steel tube couplers provide a strong and secure connection between scaffolding tubes, and they can be used alongside other connection methods such as bolts, clamps, or wedges to create a versatile and sturdy scaffolding structure. This allows for flexibility in designing scaffolding systems that meet specific project requirements.

- Q: Are steel tube couplers reusable or disposable?

- Steel tube couplers are generally reusable. These couplers are designed to securely connect two steel tubes together, providing a strong and reliable joint. Due to their durable construction and ability to withstand high loads and pressures, they can be used multiple times, making them a cost-effective choice for many construction and engineering applications. However, it is important to note that the reusability of steel tube couplers may depend on various factors such as the specific design, quality, and condition of the coupler, as well as the type of application and the level of stress it experiences. Regular inspection and maintenance can help ensure the continued reusability of these couplers, allowing them to be used in multiple projects or installations.

- Q: Are steel tube couplers compatible with scaffolding systems from different manufacturers?

- Steel tube couplers are typically designed to be compatible with most scaffolding systems from different manufacturers. This is because steel tube couplers follow standard dimensions and specifications set by industry organizations such as the National Access and Scaffolding Confederation (NASC) and the Occupational Safety and Health Administration (OSHA). These standards ensure that steel tube couplers can be used interchangeably with scaffolding systems from different manufacturers, as long as they meet the same industry standards. However, it is always recommended to consult the specific manufacturer's guidelines and specifications to ensure proper compatibility and safety.

- Q: Are steel tube couplers compatible with scaffolding systems that require specialized accessories, such as scaffold hoists or pulleys?

- Scaffold hoists or pulleys can be safely and effectively integrated into scaffolding systems that require specialized accessories such as steel tube couplers. These couplers are designed to securely connect scaffolding tubes, providing stability and support for various applications. They are versatile and can accommodate different types of accessories, including scaffold hoists or pulleys. Following the manufacturer's guidelines and using the appropriate couplers ensures the safe integration of these accessories. This compatibility enhances functionality and efficiency in construction or other industries that rely on specialized accessories.

- Q: What is the minimum spacing between the crossbar and the pole spacing of the scaffold?

- According to JGJ130-2011 "construction of fastener type steel pipe scaffold safety technical specifications" is just that should not exceed 50 meters. Did not explain the restrictions on workers to shelve construction. May be specific to a more specific program scaffolding calculation book to calculate. Should be and step, span, even wall pieces, scissors, and other specific size settings associated.

- Q: How are steel tube couplers secured to the scaffolding structure?

- Steel tube couplers are secured to the scaffolding structure through a combination of tightening bolts and nuts, ensuring a secure and stable connection between the coupler and the scaffold tube.

- Q: I heard this song today where this guy is singing about a scaffold of lighters... what the heck is that? I know what a scaffold is and I know what lighters are but a scaffold of lighters???

- It's lighters by Bruno mars and he's saying 'a sky full of lighters'

- Q: In the town to invest fastener steel scaffolding rental needs of how large

- The specification is to build the site configuration of the reference book, the higher authorities to check when you check the specification configuration is complete, so the specification is to buy from the bookstore, can not use the electronic version of theThe first part of the civil engineering construction national standards 1

Send your message to us

Frame-Connected Adjustable and Safety Scaffolding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches