Frame-Connected Scaffolding with Resonable Structure

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

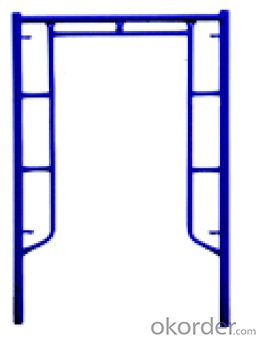

1. Structure of Frame-Connected Scaffolding

Presented like a shape of door , Frame-connected Scaffolding includes main frame, horizontal frame, cross brace, stage board and adjustable base. In order to display frame with couple system enough, good performance of stability ,firm structure of the whole, easy and fast to assemble and dismantle without any tools, safe working at height especially, and it is ideal material for construction engineering.

It can be widely used for industrial and civil construction and maintenance, such as workshop, large gymnasium, conference& exhibition center conversation, billboard, market, dock, tunnel, subways, etc. used for mobile working platform installation of electrical & mechanical engineering, ship repair and other decoration engineering, for building temporary stand ,with simple roof frame, frame-connected Scaffolding can from temporary dormitory, depot and work shed.

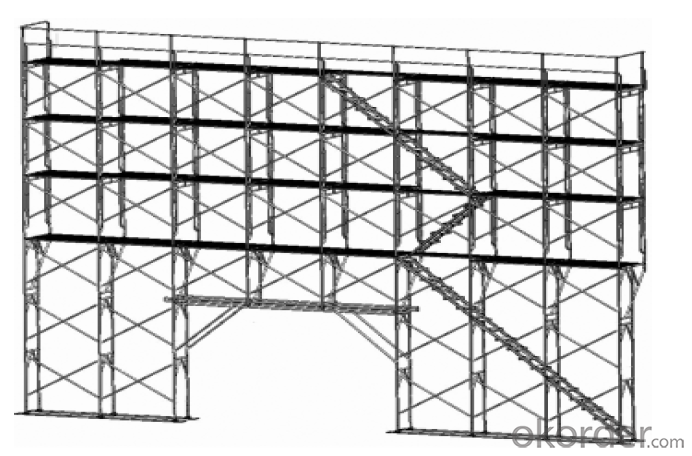

2. Main Features of Frame-Connected Scaffolding

.Reasonable structure, simple assembly, quick operation, safety& reliability.

.Easy to transport and knock down, high efficiently, save massive manpower and resource

.Easy to carry and operate with the weight about 20kg/p

.Assembly& disassembly with hands only to improve the efficiency highly, frame-connected scaffolding of assembly &disassembly saves half of the time than fasten steel-pipe scaffolding, and two third of the time than bamboo scaffolding.

.Widely usage, reasonable and practical, low aggregate cost.

3. Frame-Connected Scaffolding Images

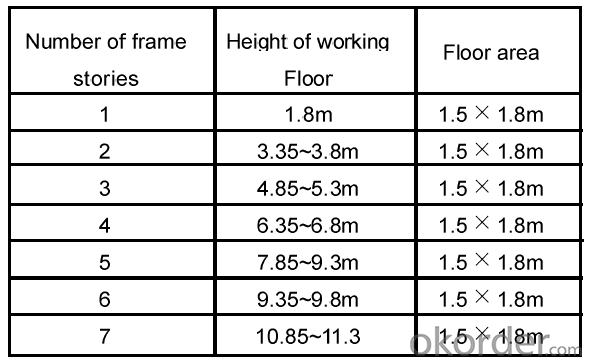

4. Frame-Connected Scaffolding Specification

.Maximum breaking load: 22.2t

.Safe working loads on jack components(safety factor:3.5)

5. FAQ of Frame-Connected Scaffolding

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Frame-Connected Scaffolding, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Frame-Connected Scaffolding cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Frame-Connected Scaffolding, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Can steel tube couplers be used to connect diagonal braces in scaffolding?

- Yes, steel tube couplers can be used to connect diagonal braces in scaffolding. Steel tube couplers are commonly used in scaffolding construction to connect different components together, including diagonal braces. These couplers provide a strong and secure connection between the tubes, ensuring stability and safety in the scaffolding structure. They are designed to be easily installed and removed, allowing for flexibility and adjustment in the scaffolding system. Overall, steel tube couplers are an effective and reliable solution for connecting diagonal braces in scaffolding.

- Q: What is the typical maintenance routine for steel tube couplers in scaffolding?

- The typical maintenance routine for steel tube couplers in scaffolding involves regular inspections to check for any signs of wear, damage, or corrosion. These inspections should be done before and after each use of the scaffolding system. Additionally, the couplers should be cleaned and lubricated regularly to ensure smooth operation and prevent rust formation. If any issues are detected during the inspections, the couplers should be replaced or repaired immediately to maintain the safety and integrity of the scaffolding structure.

- Q: 6 meters high outside the wall to be maintenance, scaffolding how to count

- Polystyrene foam board polystyrene Foam board is one of the three common wall insulation materials

- Q: Are there any specific standards or regulations for steel tube couplers used in scaffolding?

- Yes, there are specific standards and regulations for steel tube couplers used in scaffolding. In many countries, including the United States, the United Kingdom, and Australia, these standards and regulations are enforced to ensure the safety and integrity of scaffolding structures. One of the most widely recognized standards for scaffolding couplers is the EN 74 standard, which is used in Europe and other parts of the world. This standard provides specifications and requirements for couplers, including their dimensions, materials, and mechanical properties. It also covers testing methods and procedures to ensure compliance with safety standards. In the United States, the Occupational Safety and Health Administration (OSHA) regulates scaffolding safety, including the use of couplers. OSHA standards require scaffolding components, including couplers, to meet specific requirements for strength, durability, and load capacity. These standards also outline the proper installation and use of couplers to ensure worker safety. Similarly, in the United Kingdom, the Health and Safety Executive (HSE) provides regulations and guidance on scaffolding safety. The NASC (National Access and Scaffolding Confederation) also provides industry-specific guidance and recommendations for scaffolding couplers. These guidelines outline the minimum requirements for coupler materials, dimensions, and load capacity, as well as the proper installation and inspection procedures. It is important for scaffolding companies and workers to adhere to these standards and regulations to ensure the safety of the scaffolding structure and the individuals working on or around it. Regular inspection and maintenance of couplers are also essential to identify any potential issues or defects that may compromise their performance. Overall, the use of steel tube couplers in scaffolding is subject to specific standards and regulations in various countries to ensure the safety and integrity of scaffolding structures. Compliance with these standards is crucial for maintaining a safe working environment in the construction industry.

- Q: Can steel tube couplers be used in scaffolding systems that need to accommodate special access requirements?

- Indeed, steel tube couplers are capable of being utilized in scaffolding systems that necessitate the accommodation of distinctive access prerequisites. These versatile steel tube couplers possess the ability to connect scaffolding tubes at diverse angles and positions, thereby enabling the creation of customized scaffolding structures. This adaptability renders them suitable for scaffolding systems that require adjustment to cater to exceptional access requirements, including facilitating entry into irregularly shaped or difficult-to-reach areas. Moreover, the strength and dependability of steel tube couplers are well-regarded, guaranteeing the stability and safety of the scaffolding system, even when confronted with special access demands.

- Q: What are the typical installation methods for steel tube couplers in scaffolding structures?

- Steel tube couplers in scaffolding structures can be installed using different methods. One common approach is the "putlog" or "single coupler" installation. Here, a spanner or wrench is used to tighten the coupler securely onto a single scaffold tube, establishing a connection that contributes to the stability of the scaffold. Alternatively, the "double coupler" installation involves connecting two scaffold tubes with two steel tube couplers, one on each side. By tightening the couplers, a strong connection is formed between the tubes, enhancing the overall stability of the scaffold. The "swivel coupler" installation is another widely used method. This type of coupler permits a 360-degree rotation, allowing the scaffolding to be set up at different angles and configurations. Swivel couplers are particularly useful in situations where adaptability and flexibility are necessary. Lastly, the "sleeve coupler" installation method entails sliding a steel tube through a sleeve coupler, which is then tightened to secure the connection. This method is typically employed when joining two tubes end-to-end to create longer scaffold spans. In summary, the installation of steel tube couplers in scaffolding structures involves securely tightening the couplers onto scaffold tubes to establish strong and stable connections. These methods guarantee the safety and reliability of the scaffolding structure during construction or maintenance projects.

- Q: Are steel tube couplers resistant to wear and tear?

- Steel tube couplers possess a remarkable resistance to wear and tear. Thanks to its durability and strength, steel is an optimal material option for tube couplers. These couplers are specifically designed to endure heavy loads and withstand various environmental conditions. Consequently, they are frequently utilized in construction projects where they are frequently exposed to rigorous use and harsh elements. Steel tube couplers boast an extended lifespan and can withstand the repetitive stress and strain associated with joining and disconnecting tubes. Moreover, they exhibit resistance to corrosion, which further enhances their longevity. All in all, steel tube couplers are an enduring and dependable solution that can withstand the effects of wear and tear over time.

- Q: How do you dismantle and remove steel tube couplers from scaffolding?

- In order to dismantle and eliminate steel tube couplers from scaffolding, a systematic approach and a few tools are required. The steps involved are as follows: 1. Gather the necessary tools: Make sure to have a hammer, a wrench, and a scaffold spanner. It is important to ensure that the sizes of these tools match the couplers being worked with. 2. Evaluate the scaffolding structure: Prior to commencing the dismantling process, assess the scaffolding structure to identify the couplers that need to be removed. Take note of their positions and understand their connections to the tubes. 3. Loosen the coupler nuts: Use a scaffold spanner or wrench to loosen the nuts that secure the couplers to the tubes. Turn them in a counterclockwise direction to release their grip. In cases where the nuts are stuck or rusted, tapping the spanner gently with a hammer may be necessary to loosen them. 4. Remove the coupler nuts: Once the nuts are loosened, carefully unscrew them completely and set them aside. Exercise caution to avoid dropping them, as they could be lost or cause injury if they fall from a height. 5. Separate the scaffolding tubes: With the nuts removed, the scaffolding tubes can now be separated by pulling them apart. It may be necessary to wiggle or twist the tubes slightly to overcome any residual friction. 6. Extract the couplers: After separating the tubes, the couplers can now be removed from the scaffolding structure. Firmly grasp the coupler and gently tap it from the side or underneath with a hammer to dislodge it. If required, use a pair of pliers to provide additional leverage. 7. Repeat the process: Repeat this process for each coupler that needs to be removed from the scaffolding structure. Take your time to ensure that each step is executed safely and efficiently. 8. Inspect and replace: After removing the couplers, inspect them for any damage or signs of wear. If any couplers are broken or show deterioration, they should be replaced before reassembling the scaffolding. It is important to prioritize safety when working with scaffolding. Ensure that the structure is stable and secure, wear appropriate personal protective equipment, and adhere to any specific guidelines provided by the manufacturer or your supervisor.

- Q: Can steel tube couplers be used for scaffolding projects with unique architectural requirements?

- Yes, steel tube couplers can be used for scaffolding projects with unique architectural requirements. Steel tube couplers are versatile and can be easily adjusted to fit different angles and configurations, making them suitable for accommodating unique architectural designs. They provide a strong and reliable connection between steel tubes, ensuring the stability and safety of the scaffolding structure. Additionally, steel tube couplers are highly durable and can withstand heavy loads, making them ideal for supporting the weight of scaffolding in complex architectural projects. Overall, steel tube couplers are a flexible and practical choice for scaffolding projects with unique architectural requirements.

- Q: im getting it done

- Top of the ear is a bit tougher than the side (presuming that're the direction you're going), but it's not too bad.

Send your message to us

Frame-Connected Scaffolding with Resonable Structure

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches