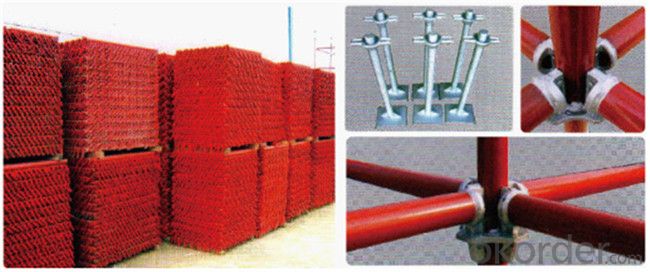

Pulley-clip Scaffolding

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pulley-clip Scaffolding

Features:

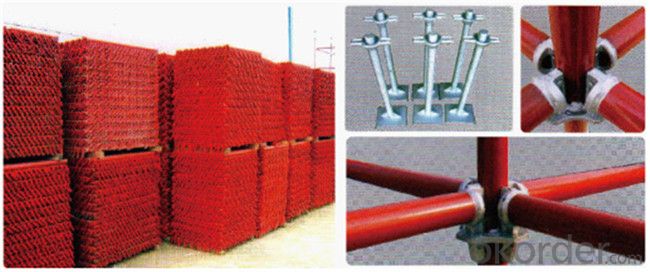

①Safe & Stable The pulley-clip scaffold has perfect mechanical properties:The theoretical data of the eccentric distance of the vertical pole joints of pulley-clip scaffold is zero,which improves the axial compressive strength of the vertical poles,plays the mechanical properties of the material and impressive entire stability.Furthermore,the tensile forces and pressures on each joint of the pulley-clip scaffold in operation are in reasonable distribution state,which ensures the pulley-clip scaffold has perfect rigidity and entire stability.

②Efficient & Economic By the statistics,the connecting and dismounting efficiency of pulley-clip scaffold is 6-8 tines higher than coupler scaffold,5-7 times higher than frame scaffold,3-4 times higher than cup-lock scaffolding.The steel tube scaffold does not have any special locking part structurally, which greatly improves the locking reliability..The connecting and dismounting speed is fast with distinct effect in high rise and high altitude operation.Simple process saves construction time and effort,and reduces labor intensity.

③Ultra-low Loss Realize that the steel scaffold does not have moving spare parts strcturally and solve the easy loss,

Easy damage and uneasy transportation problems of the spare parts of the scaffold. The building and dismounting are safer with more distinct role in high-rise and high altitude operations. The lost and stolen rate is below 0.5%.

④Wide Application It adapts to the technical characteristics and economic characteristics of the engineering, can be used independently and solves the problem of joint use with the cup lock scaffold, which provides convenience in technology and economic benefit for the building site which has used cup lock scaffold in large amount to use pulley-clip scaffold.

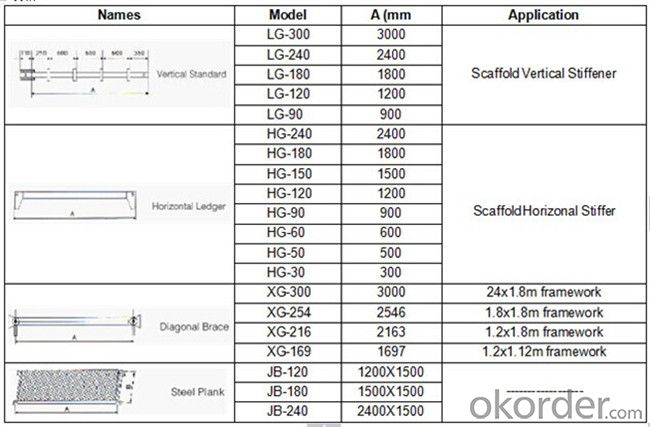

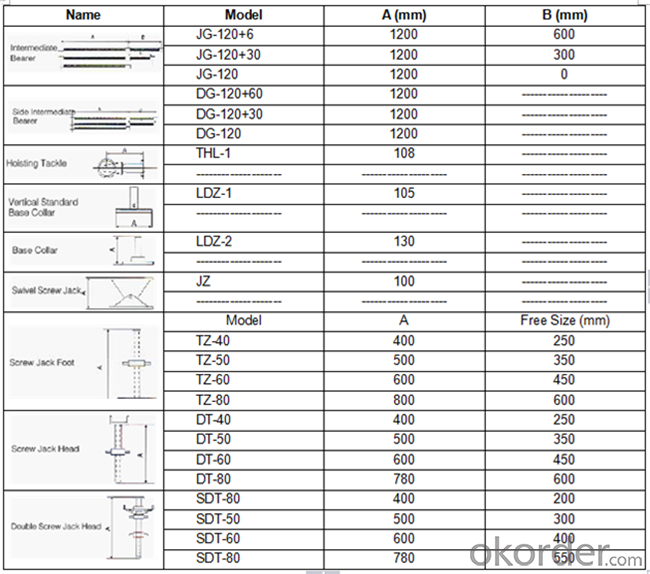

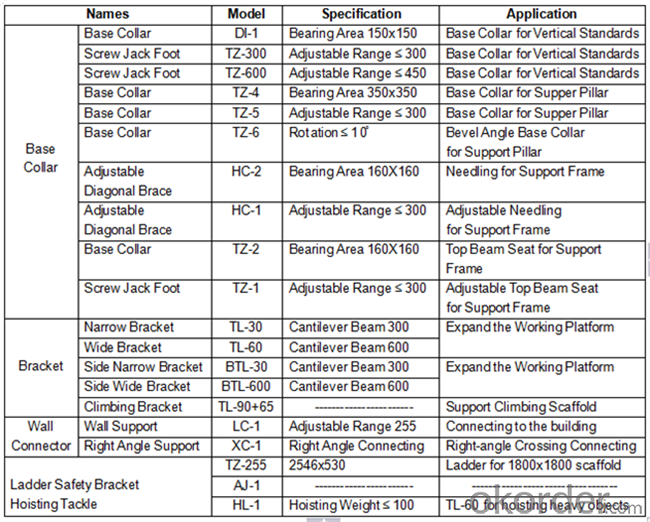

Parameters:

- Q: Can steel tube couplers be used in scaffolding projects with limited foundation support?

- Yes, steel tube couplers can be used in scaffolding projects with limited foundation support. Steel tube couplers are widely used in scaffolding systems to connect steel tubes together, providing a strong and secure structure. They are designed to withstand heavy loads and are commonly used in construction projects where safety is a top priority. In scaffolding projects with limited foundation support, steel tube couplers can be especially beneficial. They allow for versatile and flexible scaffolding designs, as they can be easily adjusted and repositioned to accommodate different ground conditions. This flexibility helps in redistributing the load across multiple points of support, minimizing the impact on the limited foundation support available. Furthermore, steel tube couplers are known for their durability and strength. They can provide a stable and secure connection between scaffolding components, ensuring the safety of workers and materials. This is particularly important in projects with limited foundation support, as it is crucial to have a reliable and sturdy scaffolding structure. However, it is always recommended to consult with a structural engineer or scaffolding expert before using steel tube couplers in projects with limited foundation support. They can assess the specific site conditions and provide guidance on the proper design and use of scaffolding systems to ensure safety and compliance with local regulations.

- Q: What is the maximum load capacity of steel tube couplers?

- The maximum load capacity of steel tube couplers depends on various factors such as the size and design of the coupler, the type of steel used, and the specific application it is being used for. It is recommended to consult the manufacturer or refer to the product specifications to determine the exact maximum load capacity of a particular steel tube coupler.

- Q: What are the typical material specifications for steel tube couplers used in scaffolding?

- The typical material specifications for steel tube couplers used in scaffolding are usually made of high-quality steel, with a minimum tensile strength of 350 MPa and a minimum yield strength of 235 MPa. They are typically galvanized to provide corrosion resistance and have a standard diameter of 48.3 mm to fit standard scaffolding tubes. Additionally, they should comply with relevant industry standards and regulations, such as EN 74 and ANSI/SSFI SC100-5/05.

- Q: Can steel tube couplers be used for creating cantilevered or suspended scaffolding structures?

- Yes, steel tube couplers can be used for creating cantilevered or suspended scaffolding structures. Steel tube couplers are commonly used in scaffolding systems to connect tubes together, providing a secure and stable framework for construction work. Cantilevered or suspended scaffolding structures require additional support and stability due to their unique design, and steel tube couplers can effectively meet these requirements. By securely connecting the steel tubes, the couplers ensure that the scaffolding structure remains strong and safe for workers. Additionally, steel tube couplers are versatile and can be easily adjusted or repositioned to accommodate the specific needs of a cantilevered or suspended scaffolding structure. Overall, steel tube couplers are a reliable and suitable choice for creating such scaffolding structures.

- Q: Can steel tube couplers be used in both temporary and permanent scaffolding structures?

- Yes, steel tube couplers can be used in both temporary and permanent scaffolding structures. Steel tube couplers are versatile and reliable components that are commonly used in scaffolding systems to connect steel tubes together. These couplers provide a secure and efficient way to join the tubes, ensuring the stability and integrity of the structure. Whether it is for a temporary scaffolding structure that will be dismantled after use or a permanent scaffolding structure that will remain in place for an extended period of time, steel tube couplers can be used with confidence. They are designed to withstand the loads and forces exerted on the scaffolding, providing a safe working platform for construction workers.

- Q: How do steel tube couplers ensure the vertical alignment of scaffolding poles?

- To guarantee the vertical alignment of scaffolding poles, steel tube couplers are purposefully designed. Made of high-quality steel, these couplers possess a firm grip on the tubes, ensuring a secure connection. The unique design of steel tube couplers serves as a primary method for achieving vertical alignment. Typically equipped with multiple bolts or clamps, these couplers can be tightened to securely hold the tubes in position. This design allows for precise adjustments, guaranteeing perfect vertical alignment of the scaffolding poles. Furthermore, the construction of steel tube couplers is rugged and durable, enhancing their ability to maintain vertical alignment. The steel material used in their production is renowned for its strength and stability, enabling the couplers to endure the weight and pressure exerted on the scaffolding. By firmly securing the tubes together, steel tube couplers eliminate any potential movement or shifting between the poles. This eliminates the risk of the scaffolding structure leaning or tilting, ensuring its stability and safety. In conclusion, steel tube couplers are vital in upholding the vertical alignment of scaffolding poles. Their strong grip, precise adjustments, and sturdy construction guarantee the security and stability of the scaffolding structure, providing a dependable platform for workers to carry out their tasks safely.

- Q: Can steel tube couplers be used for angled or sloped scaffolding structures?

- Indeed, angled or sloped scaffolding structures can make use of steel tube couplers. These couplers, being versatile connectors, are specifically engineered to link scaffold tubes at varying angles, enabling the construction of diverse scaffolding arrangements. By employing these couplers, one can create scaffolding structures that possess varying slopes or angles, thereby catering to the unique demands of any construction endeavor. Consequently, the utilization of steel tube couplers guarantees a dependable and steadfast junction between the tubes, ultimately lending robustness and stability to the scaffolding structure.

- Q: Can steel tube couplers be used for curved scaffolding structures?

- Indeed, curved scaffolding structures can utilize steel tube couplers. These couplers possess great versatility, enabling the connection of steel tubes at different angles and positions. This adaptability facilitates the construction of curved scaffolding structures. By employing various coupler types, such as swivel or adjustable couplers, the steel tubes can be connected and manipulated to achieve the desired curved configuration. Consequently, steel tube couplers prove to be an optimal selection for erecting scaffolding structures that demand curved or unconventional shapes.

- Q: Are steel tube couplers suitable for scaffolding projects with specific load-bearing requirements?

- Yes, steel tube couplers are suitable for scaffolding projects with specific load-bearing requirements. Steel tube couplers are strong, durable, and reliable, making them ideal for supporting heavy loads in scaffolding structures. They provide a secure connection between steel tubes, ensuring stability and safety in construction projects that have specific load-bearing requirements.

- Q: How do steel tube couplers ensure the stability and safety of a scaffolding structure?

- The stability and safety of a scaffolding structure heavily rely on steel tube couplers. These couplers have a vital role in connecting and securing the steel tubes that form the framework of the scaffolding. Primarily, steel tube couplers establish a firm and inflexible connection between the steel tubes. Equipped with bolts, nuts, and pins, they ensure that the tubes remain fixed in position, even when subjected to heavy loads or external forces. By preserving the structural integrity of the scaffolding, the couplers contribute to its stability and prevent any potential collapse or failure. Additionally, steel tube couplers are specifically designed to evenly distribute the load across the entire scaffolding structure. During use, workers and materials exert various forces on different parts of the structure. The couplers facilitate the transfer of these forces from one tube to another, resulting in a spread-out load and reduced stress on individual components. This uniform distribution of forces eliminates any localized weak points and guarantees the overall stability of the scaffolding. Furthermore, steel tube couplers offer flexibility and adjustability in scaffolding structures. They enable easy assembly and disassembly, allowing workers to modify the structure as necessary. With a secure and easily adjustable connection, the couplers ensure that the scaffolding remains stable and safe throughout its use. Apart from their structural advantages, steel tube couplers exhibit high resistance to corrosion and deterioration. This is particularly important for scaffolding structures exposed to outdoor elements or harsh working environments. By utilizing high-quality steel couplers, the risk of corrosion-related degradation or failure is minimized, further enhancing the safety and longevity of the scaffolding. In conclusion, steel tube couplers are indispensable components of scaffolding structures that guarantee stability and safety. They establish secure connections between steel tubes, distribute loads evenly, provide flexibility and adjustability, and offer resistance to corrosion. By incorporating these couplers into scaffolding designs, construction workers can confidently carry out tasks at elevated heights, knowing that the structure is dependable, stable, and safe.

Send your message to us

Pulley-clip Scaffolding

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords